Zoltek, A + Composites present novel CFRTP UD tape

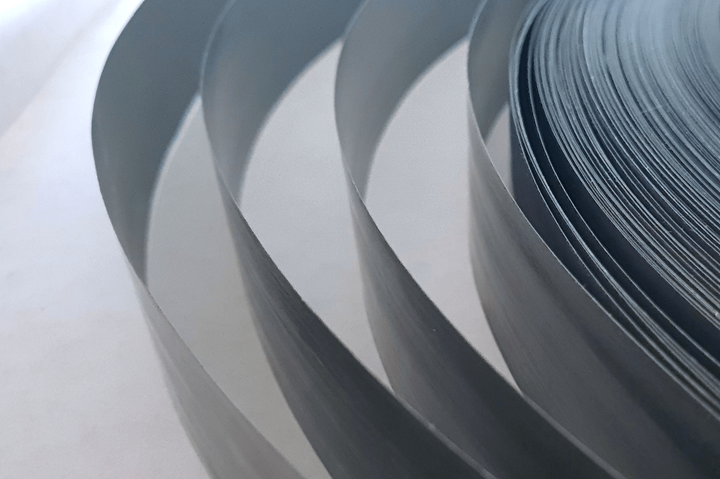

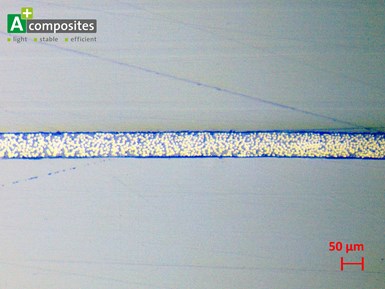

50K carbon fiber tow impregnated with polypropylene features 50 µm thickness, offers potential for weight savings and increased mechanical performance.

Share

Read Next

Industrial-grade carbon fiber company Zoltek Companies Inc. (St. Louis, Mo., U.S.) has partnered with A + Composites (Weselberg, Germany), a tailor-made fiber-reinforced composites manufacturer, to create a carbon fiber-reinforced polypropylene unidirectional (UD) tape.

According to both companies, the material possesses distinctive properties and features, including 50% fiber volume fraction (FVF); 50 µm thickness; 50K Zoltek PX35 carbon fiber tow; and 50 g/m² fiber aerial weight.

“This particular UD tape is unique because the 50K large-tow carbon fiber is fully impregnated with polypropylene, while remaining extremely thin at 50 µm. Comparable thicknesses have not been achieved for fully impregnated thermoplastic carbon UD tapes in the past, especially with large-tow carbon fiber,” Jakob Goerzen, A+ Composites, explains. “Therefore, this product is on par with regular tow applications for a fraction of the cost and at full availability of industrial carbon fibers.”

According to Tobias Potyra, director of Sales EU, Zoltek, this development shows the versatility and potential of Zoltek’s 50k PX35 carbon fiber tow and the technical expertise of the engineers at A+ Composites. “Thin tapes such as these offer potential for weight savings, increased mechanical performance and are particularly suited for aesthetic applications,” Potyra says. “In addition, very small bending radii can be realized, which means, winding applications with very small diameters and tighter radii in forming processes can be achieved.”

Related Content

-

Manufacturing the MFFD thermoplastic composite fuselage

Demonstrator’s upper, lower shells and assembly prove materials and new processes for lighter, cheaper and more sustainable high-rate future aircraft.

-

Optimizing a thermoplastic composite helicopter door hinge

9T Labs used Additive Fusion Technology to iterate CFRTP designs, fully exploit continuous fiber printing and outperform stainless steel and black metal designs in failure load and weight.

-

The potential for thermoplastic composite nacelles

Collins Aerospace draws on global team, decades of experience to demonstrate large, curved AFP and welded structures for the next generation of aircraft.