Zoltek Companies, Inc.

3101 McKelvey Rd.

Bridgeton, MO 63044 US

314-291-5110

sales@zoltek.com

zoltek.com

About Zoltek Companies, Inc.

IS THIS YOUR COMPANY?

As Seen On CompositesWorld

Zoltek Companies, Inc. Supplies the Following Products

- Carbon

- Carbon, Chopped strand

- Carbon, Milled fibers

- Carbon, Multiaxial

- Carbon, Other

- Carbon, PAN-based

- Carbon, Plain-weave

- Carbon, Stitched (knitted, nonwoven)

- Carbon, Twill

- Carbon, Yarns

- Carbon/carbon composites

- Pultrusion equipment, thermoplastics

- Pultrusion equipment, thermosets

Editorial, News, and Products

-

Novel woven UD fabrics are designed for versatility, reliability

CAMX 2024: Zoltek introduces PX35UD0300EPW and PX35UD0600EPW, carbon fiber fabrics providing easy handling that have the potential to meet the evolving needs of composite applications.

-

People in composites: May 2024

Take a look at this month’s new hires, promotions and company developments from Daher, Carbon ThreeSixty, Collins Aerospace, Toray Advanced Composites, Syensqo, Zoltek, Technical Fibre Products, Bedford and Mito.

-

Automation, winding equipment meet evolving composite needs

JEC World 2024: Engineering Technology Corp. is exhibiting offerings ranging from high-speed filament winding equipment to integrated robotic solutions, in addition to new standard line of tape wrappers.

-

Zoltek founder and carbon fiber visionary Zsolt Rumy passes away at 81

Founder, CEO and board member of Zoltek Companies leaves behind significant contributions to industrial-grade carbon fiber and cross-cultural promotion.

-

Tailor-made UD tapes target application versatility

CAMX 2023: Dynamic relationships with suppliers and customers drive A+ Composites’ ability to provide a variety of UD tapes designed to meet evolving industry needs.

-

JEC Composites Innovation Award 2023 winners

The JEC Group has announced the winner for each of the ten Innovation Award categories. Learn more about the winners, their projects and future expectations in person or via livestreaming at JEC World 2023.

-

JEC Composites presents 2023 Innovation Award finalists

This year’s 30 Innovation Award finalists representing 11 categories portray excellence in composites innovation and fruitful collaboration.

-

UniFORM: High-quality, high-complex EV battery enclosures at low cycle times, low tooling costs

Stellantis subsidiary CpK Interior Products Inc. recently completed a design challenge to prove out its vacuum-assisted wet compression molding process for CFRP battery trays.

-

Zoltek, A + Composites present novel CFRTP UD tape

50K carbon fiber tow impregnated with polypropylene features 50 µm thickness, offers potential for weight savings and increased mechanical performance.

-

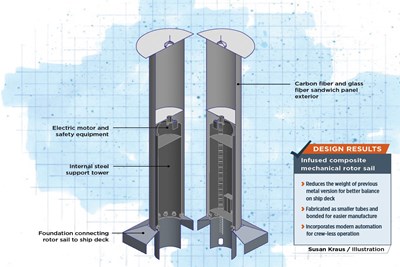

Modernizing the mechanical rotor sail

Composites are key for Norsepower’s award-winning redesign of a century-old rotor sail for reducing carbon emissions on passenger and cargo ships.

-

SMC material configurations tailored to automotive battery enclosure design

SMC battery cover offers various module configurations, levels of performance, mass and cost for electric vehicles.

-

The outlook for carbon fiber supply and demand

The picture painted at Carbon Fiber 2021 concerning the current supply and demand for carbon fiber indicates an in-flux, rapidly changing environment across a majority of end markets.

-

Zoltek to expand global large-tow carbon fiber capacity in 2023

To meet wind market demands, the 6,000-MT capacity expansion at the company’s Mexico facility will add up to 35,000 MT total global production capacity.

-

Thermoplastic tapes reinforced with textile-based PAN carbon fiber

IACMI project trials inline production of thermoplastic tapes reinforced with textile-based PAN carbon fiber.

-

Sky Advanced Materials fabrics win DNV-GL type approval

Certification for Hungary-based Sky Advanced Materials covers use of fabrics made with Zoltek PX35 50k tow carbon fiber combined with epoxy or vinyl ester.

-

"Green" carbon fiber: Renewable energy powers fiber production

Zoltek is first in the industry to use “green” electricity to produce a portion of its heavy-tow carbon fiber.

-

Composite catamaran hits high watermarks

Inspired by design elements found in racing catamarans and employing composite structures in innovative ways, Compmillennia has rolled out a fishing/excursion cat that uniquely combines high speed, great fuel economy and a smooth ride.

-

Split tow carbon fiber boosts SMC performance

Pre-spread, pre-scored tow band provides better fiber dispersion, wetout, molding properties.

-

JEC World 2019 Preview

The JEC World trade show and conference, the largest composites event in the world, will be held at the Paris Nord Villepinte Exhibition Center, March 12-14, 2019.

-

Overcoming barriers to adoption of structural autocomposites

Although much attention has been focused on material costs and development of high-rate, automated manufacturing processes for structural autocomposites, production of viable products depends on the ability to design and simulate the structures for these exciting new FRP applications.

-

Webinar: Utilizing Large Tow Textile Based Carbon Fiber for Sheet Moulding Compound

CompositesWorld is presenting a free Zoltek-sponsored webinar on Tuesday Sept. 18, at 2:00 pm EDT on carbon fiber sheet molding compound.

-

Teaming to define what automotive CFRP could be

Ford and Magna explore a high-volume chassis front subframe build from co-molded chopped fiber and noncrimp fabric SMC.

-

How is tow spread?

ITA characterizes tow spreading processes and parameters as it develops new technology to speed production (100 m/min) and reduce width variation (<1mm).

-

Rear wall reboot: One-stop, tow to tape to CFRP part

Audi and Voith Composites iterate the CFRP rear wall from R8 sports car to A8 luxury sedan via an automated production line able to output hundreds of parts per day.

-

The spread of spread tow

Advancing from “lighter and thinner” to boosting strength, stiffness, impact resistance and productivity, spread tow unlocks new applications and markets.

-

Zoltek to provide carbon fiber for Uniti electric cars

The two companies have signed a partnership agreement in which Zoltek will be the preferred supplier of carbon fiber for Uniti’s line of electric cars.

-

Zoltek expands carbon fiber operations at Hungarian facility

Zoltek will increase the plant’s production capacity by 50% to 15,000 tons produced annually.

-

Wind blade spar caps: Pultruded to perfection?

Introduced to the market about five years ago, pultruded, carbon fiber-reinforced spar caps, incorporated as the reinforcing member of wind turbine rotor blades, are a byproduct of the evolution and increasing technological sophistication of the global wind energy industry.

-

Voith unveils digital carbon fiber manufacturing line

Patented production line used to produce the carbon fiber reinforced plastic rear panel for the new Audi A8.

-

Automation, automotive, recycling and more from JEC World 2018

Mass production of automotive composites, recycling and composites in shipbuilding are just some of the themes from this year’s JEC.

-

Zoltek fiber in new electric car

Zoltek Corporation (St. Louis, MO, US), a producer of low-cost industrial grade carbon fiber, has its PX35 carbon fiber featured on the new Uniti electric car currently making waves in Sweden.

-

SMC: Old dog, more tricks

In the sheet molding compound renaissance, the advent of new resins and compounds are broadening the definition and application of this versatile family of composites.

-

SMC: Old dog, new tricks

A sheet molding compound renaissance highlights new reinforcements, new fillers, new matrices, new opportunities.

-

OOA composites in next-generation launch systems

As United Launch Alliance ULA replaces Atlas and Delta with next-generation launch rockets under the Vulcan name, supplier Ruag Space has been selected to provide lower cost/improved quality out-of-autoclave fabrication of Vulcan’s composite primary structures. Ruag will manufacture 5.4m payload fairings and 400-series interstage adapters for ULA’s Atlas V rocket.

-

Composites in Class A body panels: Evolution continues

Low-density SMCs lead the way as fiber-reinforced polymers make headway in auto components that must please the eye.

-

Aerospace growth climbs with carbon fiber

The business case for carbon fiber in narrowbodies has become a lot stronger now that these operational benefits are in evidence.

-

Carbon/epoxy Cadillac hood

Automated process for prepreg hood inner/outer cuts weight by 20% and yields Class A exterior out of the autoclave.

-

The composites super cycle — are we still living the dream?

Predicted before the 2008 recessionary crash, the super cycle’s foundations were to be built on an increasing use of composites in aircraft. How did it play out?

-

Materials & Processes: Fiber formats for composites

Fibers used to reinforce composites are supplied directly by fiber manufacturers and indirectly by converters in a number of different forms, which vary depending on the application. Here's a guide to what's available.

-

Supply and demand: Advanced fibers

Demand for advanced fiber, virgin and reclaimed, is on an upswing after a dip during the recent recession. Fiber suppliers are gearing up to meet an expected increase in demand as manufacturers in a number of composites end-markets scale up or start up part development and production programs

-

“Give us affordable carbon fiber!”

Guest columnist Dan Pichler, managing director of CarbConsult GmbH, suggests that the we need a sustained, cooperative effort in the carbon fiber supply chain. Partnering is the key.

-

Alternative precursor R&D: Lignin in the lightweighting limelight

This abundant, renewable resource shows promise as an alternative to PAN for low-cost, functional carbon fibers.

-

Carbon fiber as a replacement for glass fiber in D-LFT auto parts

Research progresses toward attainment of 80-90% of continuous carbon fiber tensile modulus in lighter parts molded from direct long fiber thermoplastic compounds.

-

Supply and demand: Advanced fibers (2015)

Demand for advanced fiber, virgin and reclaimed, is on an upswing after a dip during the recent recession. Fiber suppliers are gearing up to meet an expected increase in demand as manufacturers in a number of composites end-markets scale up or start up part development and production programs.

-

Fiber reinforcement forms

Fibers used to reinforce composites are supplied directly by fiber manufacturers and indirectly by converters in a number of different forms, which vary depending on the application. Here's a guide to what's available.

-

Pressure vessels for alternative fuels, 2014-2023

Lower fuel costs and escalating emissions standards are driving a 10 percent annual growth in alternative fuel pressure vessel sales.

-

2014 JEC Europe Review

The composites world met again in Paris, vibrant, stronger, and more forward-looking than ever before.

-

Composites the clear choice in telecom tower rehabs

Tower permit difficulties spur repairs/upgrades of aging steel structures.

-

Why are suppliers morphing into fabricators?

CT managing editor Mike Musselman asks the question and examines the forces at work to make it a compelling trend. Part I of II.

-

Designing pressure vessels for seawater desalination plants

Safe high-pressure service challenges manufacturers of composite pressure vessels.

-

IBEX 2013 Show Review

Evidence of a marine industry rebound and a trend toward supplier M&A as the world’s largest boatbuilding trade show looks ahead to smoother sailing … and Tampa.

-

Toray + Zoltek = potential game changer?

Consultant Dale Brosius, also president of Dayton, Ohio-based Quickstep Composites LLC, the U.S. subsidiary of Australia-based Quickstep Technologies (Bankstown Airport, New South Wales), sees the Toray buyout of Zoltek as a potential auto-industry game changer.

-

Toray makes waves with Zoltek purchase

Toray was already the largest carbon fiber maker in the world, and with Zoltek it not only gets bigger, but expands into new markets.

-

HPC's 20th Anniversary: Thanks to HPC’s charter advertisers

Every trade publication lives and dies by its advertisers, and those who had the gumption to ante up for HPC’s premier issue are listed here and those who are still with us (see page numbers below) are gratefully recognized with the HPC 20th Anniversary Medallion.

-

JEC Europe 2013 review

Snow in Paris slowed traffic to the show floor but did nothing to cool the enthusiasm of composites innovators in a broad range of markets.

-

Market Outlook: Surplus in carbon fiber's future?

Participants at CW’s Carbon Fiber 2012 Conference see one coming as early as 2016.

-

SPE ACCE 2012 Review

Bursting at the seams, the 12th annual Society of Plastic Engineers Automotive Composites Conference and Exhibition tops its previous bests.

-

2012 JEC Europe Highlights

JEC’s annual Paris exhibition reports impressive attendance figures as exhibitors tout big news.

-

What is carbon fiber's place in wind energy systems?

CW Conferences director Scott Stephenson shares insights fro the recent 2011 Carbon Fiber conference (Dec. 5-7, 2011, in Washington, D.C.) presented by Nirav Patel, senior lead engineer of GE Energy-Manufacturing Technology (Greenville, S.C.).

-

Automotive evolution or real revolution?

HPC's editor-in-chief Jeff Sloan asks, Are efforts by BMW and GM to put carbon composites in cars a harbinger of things to come, as we hope, or flashes in the pan?

-

2011 High-Performance Resins Highlights

Attendees reviewed the current state of advanced resin technology and the tests that lay ahead for expanding composites into new applications and markets.

-

WINDPOWER 2011 Report

Wind energy advocates, turbine builders and their suppliers, policy makers, and a growing number of wind-involved composites professionals gather where it all began.

-

Carbon fiber market: Cautious optimism

As the recession recedes, the demand for carbon fiber, and the supply to meet it, will exceed prerecession expectations.

-

Besting Big Ben: A Marvel in Makkah

Composite design makes possible the world’s largest clock and tallest clock tower.

-

Carbon Fiber: UP!

Despite 2008-2009 recession lows, prognosticators at CompositesWorld's recent Carbon Fiber Conference predict a decade of highs.

-

Corvette's carbon hood creates shock and awe

North America’s first mass-produced, all-CFRP hood raises the bar for production sports cars.

-

Wind Blade Manufacturing, Part I: M and P innovations optimize production

As demand for wind turbines reaches unprecedented levels, rotor blade manufacturers explore new production strategies, including automation and blade segmentation.

-

Building Bridges to Bridge and Building Rehab Markets

Despite a lack of standardization and education in the civil construction sector, these innovators use carbon and steel fibers to reinforce the business case for composites.

-

Friction products: Carbon fiber stopping power

Low weight, thermal shock resistance, and extreme strength drive growth of carbon-reinforced friction products and materials in brake applications.

-

Carbon fiber buys its way onboard

First used in one-off yacht and powerboat designs, where cost is no obstacle in the search for a performance edge in local regattas or around-the-world races, carbon fiber has since carved a niche in categories that were once the exclusive reserve of glass-reinforced composites, metals or wood. In applications as

-

Carbon Fiber in the Wind

Is there a market for carbon composites in wind turbine blade construction? Yes, but the real question is, how big will it be?

-

High Wind in China

China's renewable energy mandates motivate huge growth in its wind energy market, spurring production of composite components on the Chinese mainland.

-

JEC Composites 2007 Product Showcase

This year’s Parisian exhibition provides key evidence of the composites industry’s unprecedented breadth and technical sophistication.

-

Deepwater Oil Exploration Fuels Composite Production

As the price of oil on the world market continues to climb, and as untapped land and shallow offshore oil reserves become a rarity, oil exploration companies are striking out into deepwater, developing reserves beneath the ocean floor a mile or more below the water’s surface. As a result, demand for strong yet

-

JEC COMPOSITES 2007 Highlights

Advanced composites make notable marks not only in traditional aerospace apps, but in automotive, sport and infrastructure arenas as well.

-

Composites Alive And Well In Offshore Oil Applications

The petroleum industry is moving forward with many interesting projects that will increase composite demand.

-

Composites connect with the world of cabling

Composite cables prove they can handle high tension - on land, over water and under the sea.

-

Composite Wheels A First For ATV Racers

Tough, impact-resistant glass-/carbon-reinforced thermoplastic lasts longer and reduces unsprung weight for better handling.

-

COMPOSITES AND CONCRETE

The benefits of composite materials are well established in concrete reinforcement and construction.

-

A 2004 SAMPE Europe/JEC Composites Show post-show review

Paris Technical Conference marks SAMPE Europe's 25th Anniversary with myriad new developments.

-

Carbon fiber/epoxy wheels developed to replace metal wheels on large freight trailers

Semi-trailers roll lighter with Prins Dokkum's carbon fiber Dynawheels.

-

Are Hybrid Designs the Future for Composite Bridge Decks?

Teaming composites with traditional materials may be the future direction for cost-effective infrastructure replacement.

-

Carbon Composites for Sports Cars and Mass Market Cars

A confluence of market demand, new product development and competition among automakers fuels growth in use of carbon fiber composites.

-

SAMPE Wrap Up And Product Showcase

Exhibitions on both sides of the Atlantic spur optimism and spotlight innovative technology.

-

Towpreg Proves Cost-competitive For Wound Pressure Vessels

Design group's new winding option streamlines new pressure vessel development.

-

Isotruss offers amazing strength and material savings

The three-dimensional composite truss structure is the lightest and most efficient structural tube available.

-

Design Issues With Tendons

A composite tendon is essentially a rope made from small-diameter rods, which are pultruded with carbon fiber. Multiple rods are gathered together and twisted slightly to form a strand, using typical wire rope stranding methods. Depending on the performance requirements, 10 to 40 strands, about 2 to 3 inches/5

-

Composite Drill Pipe An Available Option

Lincoln has been producing flexible composite drill pipe for short-radius, horizontal drilling since 1991. Its nominal 2.375 inch /60.3 mm (OD), 30 ft/9m long pipe shaft is filament wound with 12K carbon fiber combined with glass fibers in epoxy resin over an elastomeric liner. Standard API rotary shoulder too