Dr. Andy West, Sonichem chief chemist. Source (All Images) | Sonichem

Sustainability has become an increasingly important topic for the composites industry, with increasing demand, especially from OEMs, for sustainable business practices. Sustainability includes many areas of focus with one important area being the use of biomaterials. In this installment of CW Talks, we interview Dr. Andy West, chief chemist with Sonichem, about the company’s innovative process for converting biomass into lignin, as well as other biomaterials of interest for composites manufacturing.

Read an excerpt from CW Talks Episode 44.

CW: Tell us about the kinds of products Sonichem produces.

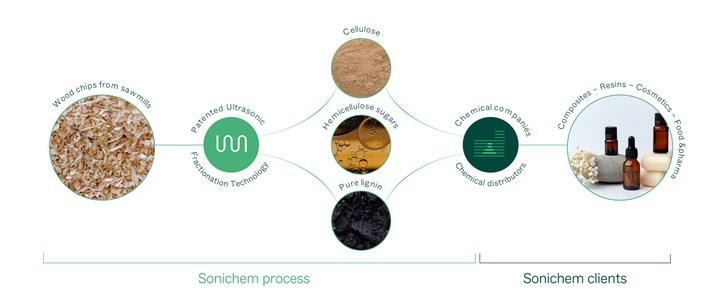

AW: We are a small company based in the Midlands in the heart of the United Kingdom, and we’re looking at converting woody biomass into platform chemicals. That sounds like a very grand ambition, but methods of doing this have been around for quite a long time. We’re using a novel patented process, which is based on ultrasound. Basically, it’s a very high frequency sound material that allows us to really target the energy input into our process to smash apart our wood into these platform chemicals. We use the analogy that this is a little bit like somebody standing outside of this tube and screaming at it. And the energy that is going into that pipe is then breaking down that woody biomass in a very efficient way into our chemicals, which in our case, are lignin, cellulose and hemicellulose, which is effectively a sugar soup.

What will we use those things for? Well, if you think about what a tree is, it’s basically the same as we might get out of the ground in a petrochemical. We can make practically everything that you get from crude oil from a tree, with the advantage, of course, that we’re cutting out millions of years of fossilization. And really importantly to our business, we’re making sure that we’re not releasing any of the carbon that's bound up in that tree into the atmosphere. So, we want to capture all the carbon that’s been captured by that tree in its growing cycle into a product without having to burn anything. And that’s really important to the ethos of our business.

Sonichem uses a novel process based on ultrasound to convert woody biomass into platform chemicals.

CW: One of the products you produce is lignin, which is of particular interest in use as a precursor for carbon fiber. Can you talk a bit about that process?

AW: I should talk a little bit about the lignin that we’re isolating, which is quite different from the material you would get from, say, the Kraft process. The Kraft process is all about making cellulose for making really good quality paper, and the lignin from that process is typically a waste product. That said, it is finding uses; it is a very valuable material in that it has a lot of carbon in there that can be used for valuable products. But, at the moment, Kraft lignin isn’t particularly useful for the chemical industry, because it has got a lot of sulfur in it, it’s generally very high in molecular weight so it’s not very soluble and it’s quite difficult to do any chemistry with it. If you were going to try and use that material in carbon fiber production, the sulfur content is way too high, so therefore, you’d need to do some chemistry on the Kraft lignin before you could use it for that application. The solubility is so low that it’s actually really difficult to incorporate it.

What’s really different about our lignin from the standard lignin you would commonly be able to get hold of, is that it has a very low molecular weight. So, it has really high solubility in a whole host of different organic solvents. It also dissolves very well in polymers. And that means that you could combine our lignin with a standard polymer, it would melt and form a fiber, and then you could make carbon fiber with it. You could also use our lignin dissolved in solvent and generated by direct electrospinning, and that is really unusual because most lignin isn't available to dissolve in that way.

So we’re part of the project with the National Manufacturing Institute of Scotland to look at how we can make carbon fiber with our lignin in a much more sustainable way, with the intention to try and replace as much petrochemical carbon as we possibly can with a bio-derived alternative.

CW: Can you talk a bit in detail about how lignin is produced using your ultrasonic process?

AW: The method of production of the lignin with our ultrasonic process means that we don’t isolate just lignin, we isolate cellulose and hemicellulose, with virtually no waste. And those three streams are fairly easy to isolate in our process, so we end up with a very pure lignin that isn’t contaminated with other things. That can then be used in a whole range of applications with the advantage of lignin being effectively the glue that holds a tree together. That means that we can then start either carrying out chemistry on that lignin, or using it as it is, into end applications including resins and coatings and paints, into composite materials, into alternative polymers; there’s a whole range of technology.

The reason that our lignin is finding all those applications is because of the unique way the ultrasound is allowing us to isolate that lignin, so it’s something that our technology has, that most of our competition doesn’t. It’s that targeted energy that allows us to isolate lignin that is low molecular weight and of a very high purity.

Related Content

Recycling hydrogen tanks to produce automotive structural components

Voith Composites and partners develop recycling solutions for hydrogen storage tanks and manufacturing methods to produce automotive parts from the recycled materials.

Read MoreJEC World 2023 highlights: Recyclable resins, renewable energy solutions, award-winning automotive

CW technical editor Hannah Mason recaps some of the technology on display at JEC World, including natural, bio-based or recyclable materials solutions, innovative automotive and renewable energy components and more.

Read MoreWatch: A practical view of sustainability in composites product development

Markus Beer of Forward Engineering addresses definitions of sustainability, how to approach sustainability goals, the role of life cycle analysis (LCA) and social, environmental and governmental driving forces. Watch his “CW Tech Days: Sustainability” presentation.

Read MoreHexagon Purus Westminster: Experience, growth, new developments in hydrogen storage

Hexagon Purus scales production of Type 4 composite tanks, discusses growth, recyclability, sensors and carbon fiber supply and sustainability.

Read MoreRead Next

Sonichem launches bio-based materials project for automotive

U.K. initiative, with the NCC, CPI, SHD Composites, Scott Bader and Polestar will work to convert biomass byproduct into lignin for automotive plastics, resins and composites.

Read MoreListen to CW Talks - the CompositesWorld Podcast

CW Talks: The Composites Podcast highlights the people and technologies shaping the world of composites. Interviews feature guests with expertise and insight about where composites have been and where they are headed.

Read MoreOn the radar: Biomaterials take center stage in composites manufacturing

CW provides examples of current developments and collaborations in sustainable fiber development, accessibility.

Read More