3A Composites Core Materials launches Engicore business line

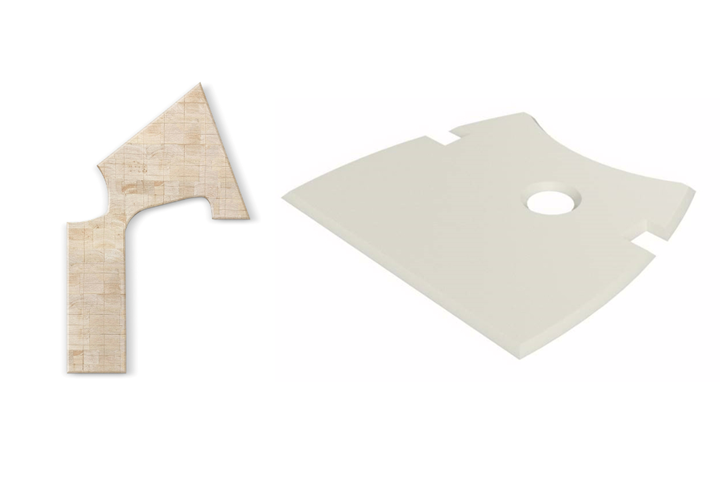

An expansion of Airex and Baltek brands, Engicore seeks to provide customers custom-shaped core solutions that are optimized for their specific manufacturing processes and standards.

At the end of 2022, 3A Composites Core Materials (Sins, Switzerland) launched the Engicore core materials product line for the North and South America markets. The portfolio expands the company’s offerings, and provides customers with custom-tailored core solutions that adapt and optimally function to their manufacturing process and standard needs. According to 3A Composites Core Materials, Engicore serves customers seeking innovation with an awareness of sustainable procurement.

The dedicated Engicore team at 3A Composites Core Materials strives for best-in-class quality management based on leading standards such as APQP and ISO certification with automated dimensional analysis processes. The goal is to provide solutions from the source and simplify the supply chain with cores that can be used directly in composite applications while maintaining material quality, properties and optimal use with the best customer service from start to finish.

Next-generation composites and design innovations meet customer needs with the right-shaped panels, an optimized focus on total cost of ownership and reduced cycle times. Green energy sources like wind and markets such as automotive, rail, aerospace, building and construction, marine and hobby, are reported to be equally served with Engicore-shaped core solutions made from Airex rigid foams and Baltek balsa wood.

Expansion of the new business line will be intensified in the Americas region in 2023, and it will be introduced to other global regions in the future.

Related Content

-

PEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

-

TU Munich develops cuboidal conformable tanks using carbon fiber composites for increased hydrogen storage

Flat tank enabling standard platform for BEV and FCEV uses thermoplastic and thermoset composites, overwrapped skeleton design in pursuit of 25% more H2 storage.

-

Sulapac introduces Sulapac Flow 1.7 to replace PLA, ABS and PP in FDM, FGF

Available as filament and granules for extrusion, new wood composite matches properties yet is compostable, eliminates microplastics and reduces carbon footprint.