AI-based production scheduling and IIoT increase productivity

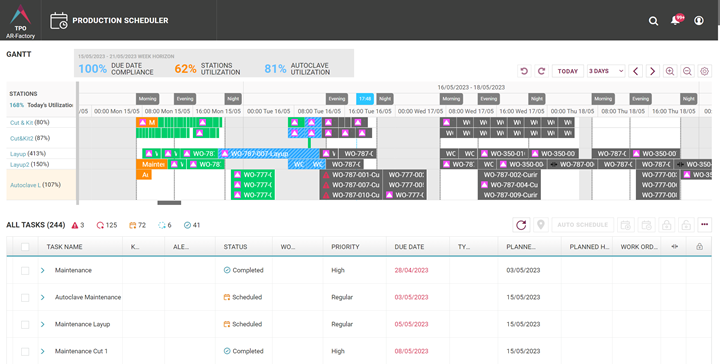

CAMX 2023: Plataine’s Production Scheduler is an intelligent and intuitive solution that combines advanced tools and algorithms for a dynamic production planning approach.

By combining the capabilities of artificial intelligence (AI), industrial internet of things (IIoT) and context-aware intelligent software in a suite of digital assistants, Plataine (Waltham, Mass., U.S.) maintains business continuity, increases throughput, and improves agility and responsiveness to market disruptions.

Plataine’s Production Scheduler is an intelligent and intuitive solution that combines advanced tools and algorithms to provide composite parts manufacturers with a dynamic approach to production planning, considering all relevant elements including human capacity, tool availability and autoclave optimization. With this information, Production Scheduler automatically generates optimized manufacturing schedules, leading to maximized capacity and throughput.

The ability to handle resource capacity is an essential feature of the new Scheduler version, according to Plataine, which enables the system to generate optimal plans while considering the availability of human and other factory resources. With the Production Scheduler, manufacturers are able to use their workforce efficiently while creating an optimized and feasible schedule. The tool support feature enables manufacturers to schedule and manage their tools, molds and resources effectively, ensuring that they are always in top condition and ready for use. The maintenance cycle monitoring also ensures that tools and machines are properly maintained, reducing downtime and increasing productivity. A new UX design is reported to be user friendly and intuitive, making it easier for planners to navigate and use the system effectively.

Plataine’s Scheduler overcomes bottlenecks in the production process, such as autoclave availability, and offers solutions to optimize production and autoclave runs. The Production Scheduler generates real-time reports that provide insights into the production process, enabling manufacturers to make data-driven decisions.

According to Plataine, its solution can quickly respond to unexpected events on the factory floor such as production delays, machine malfunctions or a shortage of staff. The automated solution reduces response time to an incident from days to minutes — the planner adjusts the schedule, approves it with the supervisor and distribute it to the floor in a few mouse clicks. This leads to higher throughput and an improved on-time delivery rate. In addition, end-to-end digitization enables enhanced productivity, quality and efficiency across industrial and business processes, allowing manufacturers to remain viable and sustainable.

Related Content

-

New Frontier Technologies launches digital twinning, high-fidelity simulation capability

3D imaging and analysis capability illustrates detailed, quality characterization and performance simulation of composites and other advanced materials that properly captures the as-manufactured component.

-

SAM XL demonstrates closed-loop digital methodologies via full-size aerocomposite parts development

PeneloPe Project’s modular, zero-defect manufacturing deliverables are being highlighted in an upcoming video that demonstrates the resulting aerospace pilot line’s feasibility.

-

Com&Sens presents workshop on fiber optic sensing for COPVs

Three-day hands-on workshop from June 11-13 in Leuven, Belgium, will equip participants with a better understanding of fiber optic sensing technology for digital manufacturing of composite tanks.