Aligned Vision brings CAD-like user interface to composites

A key feature of Align 4.0 is its CAD-like user interface, which the company claims is the only data-delivery and data-collection system for composite layup operators to use at the tool.

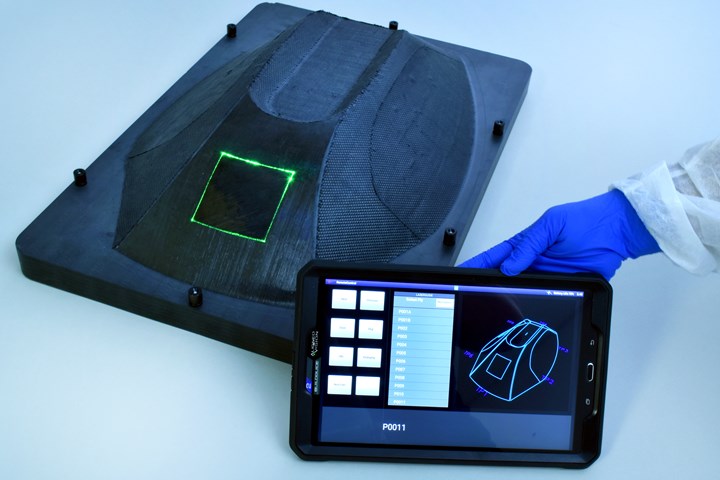

Aligned Vision (Chelmsford, Mass., U.S.) has launched its new control software, Align 4.0, an open-platform system that helps accelerate operator value-added tasks and enables Industry 4.0 connectivity for laser projection and automatic inspection processes. A key feature of Align 4.0 is its CAD-like user interface, which the company claims is a first for composites manufacturing and the only graphical interface available for use on smart mobile devices. Aligned Vision says this makes Align 4.0 the only data-delivery and data-collection system for composite layup operators to use at the tool.

New and enhanced features of Align 4.0 include 3D CAD images, a 3D ply viewer window, a PLC interface, a display of non-projected manufacturing operations and a smartview control of display screen to match operator’s view of the tool. In addition, Align 4.0 includes SystemAlign registration, which automatically registers all projectors when the first is registered. Align 4.0 supports Master.csv and multiple file formats; it also integrates of projection and inspection operations.

With the introduction of Align 4.0, the software development team at Aligned Vision is also implementing regular releases of version updates. The company says it intends to make Align 4.0 an evolving product designed to meet future requirements.

Related Content

-

Jeep all-composite roof receivers achieve steel performance at low mass

Ultrashort carbon fiber/PPA replaces steel on rooftop brackets to hold Jeep soft tops, hardtops.

-

The basics of composite drawing interpretation

Knowing the fundamentals for reading drawings — including master ply tables, ply definition diagrams and more — lays a foundation for proper composite design evaluation.

-

ASCEND program update: Designing next-gen, high-rate auto and aerospace composites

GKN Aerospace, McLaren Automotive and U.K.-based partners share goals and progress aiming at high-rate, Industry 4.0-enabled, sustainable materials and processes.