Armacell launches EPD-compliant ArmaPET Eco50 for energy-efficient construction

Armacell introduces a novel, low-density structural insulating foam based on 100% recycled PET, with improved life-cycle costs and carbon footprint.

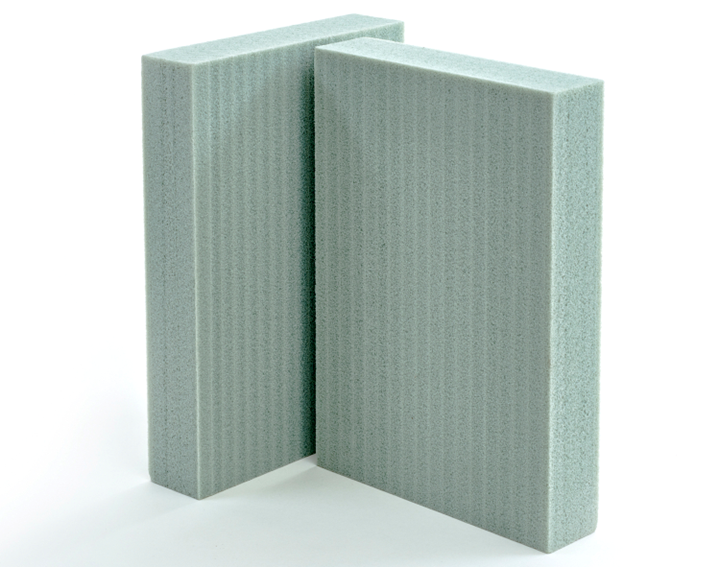

Photo Credit: Armacell

Armacell (Brampton, Ontario, Canada) a provider of engineered foams, has officially launched ArmaPET Eco50, the company’s new Environmental Product Declaration (EPD) certified solution for the structural insulation of building envelopes, roofs and floors, as well as for load-bearing applications such as under-slab insulation, both in the construction of new buildings and the renovation of older ones.

ArmaPET Eco50 is reported to be the first polymeric insulation based on 100% recycled PET (and can be recycled at end of life), combining an improved environmental profile with the stringent requirements of building construction. As part of the ArmaPET Eco range, Armacell’s low-density product is optimized for energy-efficient structural applications. It reportedly improves life-cycle costs and a building’s carbon footprint in combination with mechanical stability, low maintenance requirements, standard-compliant fire behavior and assured lifetime insulation performance.

Certified by the Institut für Bauen und Umwelt e.V. (IBU, Berlin, Germany), this EPD provides transparent, independent and reproducible analysis of the environmental impacts of ArmaPET Eco50. This includes data and figures on the extent to which the product contributes to the greenhouse effect, acidification, over-fertilization, smog and depletion of the ozone layer. The information provided is based on the international ISO 14025 standard and the European EN 15804 standard for construction products. The declaration is a cradle-to-gate EPD and registered on the IBU database system.

ArmaPET Eco50 features a density of 50 kg/m³, with insulating performance of 0.028 W/mK at 40°C. Water resistance and the foam’s closed-cell structure is said to ensure stable thermal conductivity. As these characteristics also prevent moisture penetration, mildew and rot, Armacell says they also provide long-term corrosion protection.

Additional benefits, which facilitate the installation of ArmaPET Eco50, are its broad range of thicknesses (up to 200 mm) and its flexible dimensions. In addition, it is lightweight, robust and highly compatible with organic and mineral adhesives, for fast and easy handling.

Primarily designed for building and construction applications, ArmaPET Eco50 can be used in any application requiring structural insulation, Armacell says. Armacell’s Henri Chapelle, sales and marketing manager, PET Foams, Armacell, lists applications like superstructures of refrigerated and recreational vehicles to industrial halls and food trolleys.

Related Content

-

Bio-based acrylonitrile for carbon fiber manufacture

The quest for a sustainable source of acrylonitrile for carbon fiber manufacture has made the leap from the lab to the market.

-

Plant tour: Middle River Aerostructure Systems, Baltimore, Md., U.S.

The historic Martin Aircraft factory is advancing digitized automation for more sustainable production of composite aerostructures.

-

Microwave heating for more sustainable carbon fiber

Skeptics say it won’t work — Osaka-based Microwave Chemical Co. says it already has — and continues to advance its simulation-based technology to slash energy use and emissions in manufacturing.