CAMX 2019 exhibit preview: ZwickRoell

Zwick Roell will highlight its latest developments in composites testing: the Amsler HIT 600F drop weight tester and the AllroundLine testing machine at CAMX 2019.

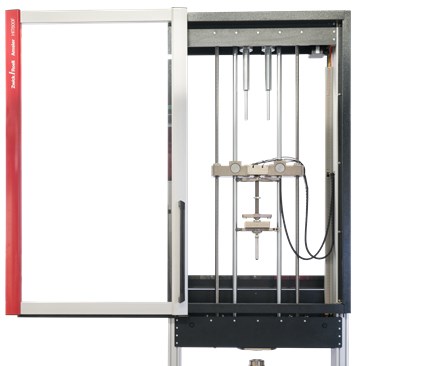

Zwick Roell (Ulm, Germany) will present flexible solutions for composites testing at CAMX 2019 to be held in Anaheim, Calif., September 23-26. Experts will be on hand to discuss the company’s latest developments in composites testing: the Amsler HIT 600F drop weight tester and the AllroundLine testing machine with grips and alignment fixtures ideal for every composites application.

The AllroundLine system for composites testing features a wide range of test fixtures that can accommodate tests under ambient and non-ambient test conditions. With the AllroundLine system, additional fixtures for three- and four-point flexure tests, inter-laminar shear strength (ILSS), and the Iosipescu V-notch shear test may be conveniently attached via slide-in inserts in place of jaws used in the pre-mounted tensile grips. The inserts facilitate rapid equipment changes, with the added advantage of maintaining the preset axial alignment of the specimen grips.

The Amsler HIT600F works in concert with the AllroundLine to perform Compression After Impact tests, which require pre-damaging of fiber-reinforced composites (CAI) to ASTM D7136, DIN EN 6038 and AITM 1.0010. Testing at low impact speeds of 2.2 m/s requires a larger drop weight; if testing at 6.6 m/s is required, acceleration is necessary. This drop weight tester caters to both situations, making it well suited to satisfy the requirements of a wide range of automotive and aerospace industry specification standards.

Common applications are:

- Puncture tests on plastics to ISO 6603-2 and ASTM D3763

- Puncture test on films to ISO 7765-2

- Pre-damaging of fiber-reinforced composites (CAI) to ASTM D7136, DIN EN 6038 and AITM 1.0010

Related Content

-

Digital chemistry platform leverages physics-based modeling for enhanced workflow

CAMX 2024: Schrödinger introduces a digital chemistry software platform, designed to enable researchers to tackle materials challenges across diverse polymer resin and carbon fiber applications.

-

CAMX 2024 Show Daily: Wednesday, Sept. 11

The second day of CAMX 2024 has all sorts of things in store for attendees, from Tuesday’s keynote centered around the world of AI, to award and poster session winners and what to look forward to at Good Day, CAMX on Thursday.

-

Getting ready for CAMX 2024

The Composites and Advanced Materials Expo’s 10th anniversary trade show and conference will be held in San Diego from Sept. 9-12, 2024.