CAMX 2021 exhibit preview: Autonational

Autonational highlights its capabilities in automated filament winding and CNC machining, including a recent case study from a utility vehicle manufacturer.

Photo Credit: Autonational

Autonational (Iljst, Netherlands) highlights its capabilities in automated filament winding and CNC machining. According to the company, composites machining operations such as milling, drilling, cutting or sanding on conventional CNC machines can cause significant wear to guides and spindles. Autonational’s newly developed CNC composites machining stations are developed from the company’s filament winder concept, including specific guiding underneath the framework and dust extraction at the milling head to minimize wear and tear.

Compared to manual positioning for conventional drilling and milling operations, Autonational’s CNC composites machining stations are said to enable better product consistency, less scrap, faster cycle times and higher output. The machines are also said to require less capital investment than conventional CNC machines of the same size, and they are designed for integration into fully automated production lines.

Photo Credit: Autonational

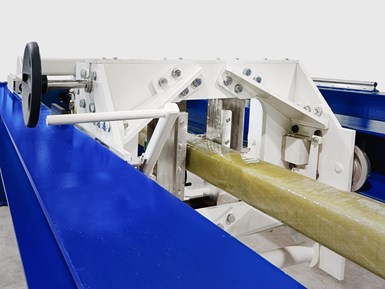

For example, the company recently announced that a U.S. utility vehicle manufacturer installed Autonational automated filament winding production lines to consolidate, enhance speed and simplify the production of its glass fiber composite booms. For use on its line of cherrypickers and utility vehicles, the manufacturing company had been producing filament-wound glass fiber composite booms on a variety of machines in several factories. The company recently worked with Autonational to develop automated production lines to combine winding, machining and post-processing operations in one newly constructed facility. The new production lines are equipped with multi-spindle winders, extractors, sanders, an oven transport system and other auxiliary equipment.

After winding, the booms are post-processed prior to installation. The outer surface is smoothed in an automated CNC belt-sander station, which is said to emit little dust and features easy and precise force-control on both a coarse and fine belt sander. The end result is an evenly distributed pressure and smooth surface finish on which coatings can be applied in a later stage.

After sanding, the booms are placed in one of three CNC machining centers, which feature a customizable 15-tool magazine including flattening mill heads, hole milling, hole drilling, chamfering, filleting, recessing and thread tapping.

This production line enables the company to cluster all its process steps into one aligned step at one facility, increasing efficiency and output. The automated process also enables flexibility and results in reduced labor costs and higher product and process quality, Autonational says.

According to Autonational, its CNC machining centers are based on its filament winder designs and developed to work with them, enabling easy integration and simplifying maintenance management.

Related Content

-

Reusable vacuum bagging solutions for composite applications

CAMX 2023: Smartech underscores its industrial reusable vacuum bagging products for reduced waste, easy debulking and the capability to be used for complex projects.

-

Wireless strain measurement system for die-cast and injection molding

CAMX 2023: Gefran introduces the QE2008-W, a non-invasive, magnetically mounted strain solution with Bluetooth transmission that uses sensors to accurately measure and maintain equipment quality.

-

Concentrated smooth dispersion simplifies electrical conductivity applications

CAMX 2024: Total Resin presents Total Nanotüp, a concentrated dispersion of carbon nanotubes in a bifunctional reactive monomer for polyester, vinyl ester, melamine and acrylic resins.

.jpg;width=70;height=70;mode=crop)