CAMX 2021 exhibit preview: Boston Materials

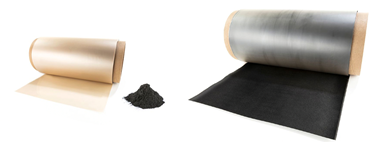

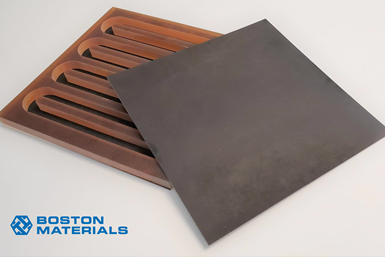

Supercomp, ZRT and Bimetal are three of Boston Material’s z-axis carbon fiber products developed via its patented magnetic alignment process.

Boston Materials (Billerica, Mass., U.S.), formed in 2016 by Anvesh Gurijala, Michael Segal and Dr. Randall Erb as a spin-out from Northeastern University (Boston, Mass., U.S.), manufactures z-axis carbon fiber products, including Supercomp, ZRT and Bimetal to aid in decarbonizing the transportation, aerospace and consumer electronics industries.

Its patented magnetic alignment process, enabling carbon fibers to be oriented vertically in a mass manufacturing process, reportedly introduces new z-axis thermal and electrical conductivity, stiffness and durability benefits to existing composite materials at lower production costs. Boston Materials says it can align pan- or pitch-based fibers including those from reclaimed or recycled sources, providing a route forward for circularity in the composites market while also enabling up to 80% in greenhouse gas (GHG) emission savings compared to standard composite materials and metals.

Applications include thermal management for enclosures, integration of lightning strike protection (LSP), increased delamination resistance and vibration damping and local reinforcement, the latter having the ability, for example, to boost fastener pull-out strength by 50%.

Boston Materials uses its scaled-up alignment process to produce a growing family of products. Supercomp, for example, is a z-axis carbon fiber film laminated to standard woven, braided, MDWK and UD prepregs or dry reinforcements. The original product from Boston Materials was launched in 2019 and used in tooling, snowboards, skis, reflector dishes and other industrial applications. In 2020 this product was scaled to a 60″ width with a capacity for one million square meters per year and growing.

ZRT is a standalone, dry, all-z-axis layer sold as a local reinforcement, surface ply or integrated into thermoset prepregs. ZRT is suited for thermoplastic composite films leveraging high-performance polymers such as LMPAEK, PEEK, PEI, PA6, PA11, PPS, PC and more. The ZRT family of products are reportedly designed to enhance thermal management, EMI shielding and through-thickness mechanical properties in electric vehicle (EV), consumer electronics and aerospace applications.

Finally, Bimetal is the company’s z-axis carbon fiber film sandwiched between metal skins (titanium, sheet metal, aluminum) offering performance parity with monolithic sheet metal at up to 50% less weight, and aimed at stamp-formed sheet metal parts in automotive applications. The company claims that Bimetal can be shaped into contoured geometries for durability, flexural strength and density improvements while maintaining a metallic surface finish.

Related Content

-

Plant tour: Spirit AeroSystems, Belfast, Northern Ireland, U.K.

Purpose-built facility employs resin transfer infusion (RTI) and assembly technology to manufacture today’s composite A220 wings, and prepares for future new programs and production ramp-ups.

-

Plant tour: Middle River Aerostructure Systems, Baltimore, Md., U.S.

The historic Martin Aircraft factory is advancing digitized automation for more sustainable production of composite aerostructures.

-

Welding is not bonding

Discussion of the issues in our understanding of thermoplastic composite welded structures and certification of the latest materials and welding technologies for future airframes.