CAMX 2021 exhibit preview: Calyxia

Calyxia's microencapsulation technology can protect reactive, functional and optical additives even in extreme temperature and shear processing conditions.

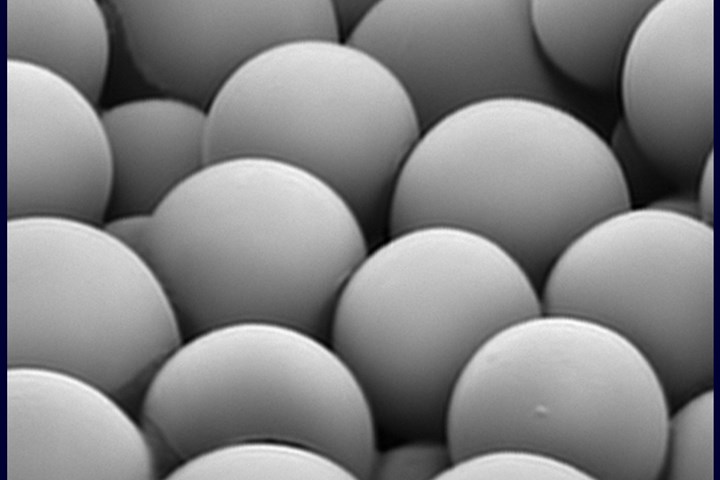

Calyxia (Bonneuil-sur-Marne, France) has developed a microencapsulation technology and process to produce what the company says are the first sealed, process-resistant and customizable microcapsules. According to Calyxia, this technology expands the performance potential and the scope of use of specialty chemicals.

Calyxia says its technology can protect reactive, functional and optical additives even in extreme temperature and shear processing conditions (extrusion, injection, compression molding, film casting).

More specifically, Calyxia technology can protect process additives (catalysts, accelerators, curing agents) from premature reaction during processing, and then deliver the additive on command during curing. This reportedly provides a significant advancement in terms of process and performance control. In addition, the Calyxia technology can protect functional additives (anti-wear, anti-abrasion) against degradation, cross-reaction or instability during processing. Anti-wear/abrasion additives are then delivered only in the event of wear or abrasion. Calyxia says functional additives enhance both the performance and the lifetime of the final product. Calyxia’s microencapsulation technology is also able to fully protected optical additives (pigments, liquid crystals, dyes) throughout the lifetime of the product.

Calyxia says its microencapsulation technology has been successfully validated with many large actors in high-performance plastics, electronics materials, adhesives and coatings applications to provide new features to materials or improve the performance of current materials.

Related Content

-

Isobaric double belt press is well suited to continuous production

CAMX 2023: Flexible and robust double belt presses from Held Technologie are adaptable to various base composite material requirements to produce top-quality, long-lasting products.

-

Cutting supplies, equipment enhance composites testing in the lab

CAMX 2024: On display at Extec’s booth is the Labcut 5000 precision composite plate saw, Nikon MA200 inverted metallurgical microscope and Labpol 12 automatic grinder/polisher.

-

Wireless strain measurement system for die-cast and injection molding

CAMX 2023: Gefran introduces the QE2008-W, a non-invasive, magnetically mounted strain solution with Bluetooth transmission that uses sensors to accurately measure and maintain equipment quality.

.jpg;maxWidth=300;quality=90)