CAMX 2021 exhibit preview: Europe Technologies

Europe Technologies highlights its robotic finishing cells and ultrasonic cutting solutions.

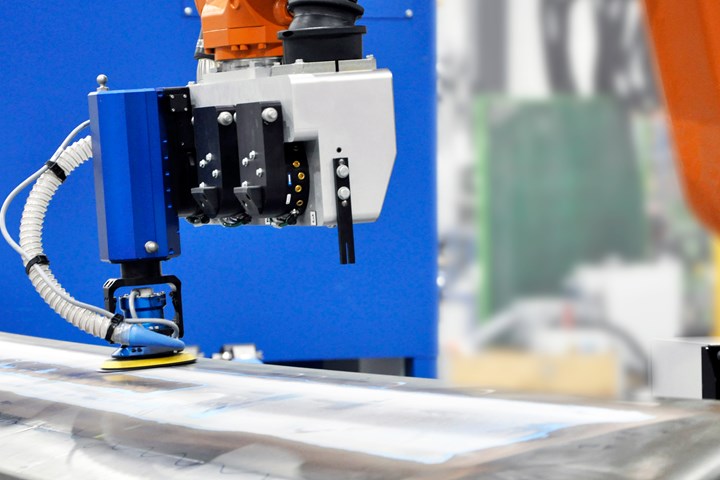

GEBE2 robotic composite finishing cell. Photo Credit, all images: Europe Technologies

Exhibiting at the Business France booth, Europe Technologies (Carquefou, France) highlights its adaptive composites manufacturing and finishing solutions, particularly its GEBE2 robotic machining cells and SONIMAT ultrasonic cutting solutions. The company provides robotized processes for sanding and acoustic drilling, as well as handheld systems and embeddable end effectors for ultrasonic cutting and welding.

GEBE2 brand solutions include robotic finishing cells with multi-spindle heads, for greater flexibility and reduced costs compared to conventional machines. A second robot can be added to change over drill bits for additional autonomy.

Another optional add-on for GEBE2 is a smart end effector for sanding operations. Designed to replace manual sanding efforts and to increase quality and consistency, the end effector is equipped with a random orbital electric sander and a compliant device that applies a constant force in all directions.

SONIMAT ultrasonic cutting solution.

In addition, Europe Technologies and Secam Fixing Solutions (Marnaz, France) have partnered on a robotized potted-in insert solution for composite sandwich panels. Part of the GEBE2 brand, this solution was designed to solve challenges in lightweighting automotive parts and to replace conventionally manual fixing processes for sandwich panels. The robotized potted-in insert solution is said to automate, simplify and facilitate the fixing of composite and metal honeycomb sandwich panels, including Nomex and aluminum.

The SONIMAT brand has been providing ultrasonic cutting solutions for composite materials for more than 25 years. Advantages include no fraying, reduced cutting effort, increased blade lifetime and cauterization of products and SONIMAT is said to fit manual or automated needs. The technology is available in a portable system or with a range of end effectors such as robotic cells, CNC machines and XY tables.

Related Content

-

State-of-the-art composites cutting, machining solutions ensure accuracy, ease of operation

JEC World 2024: Compcut is presenting its advanced composites saw (ACS) and precision composite router (PCR), in addition to inviting attendees to bring their own materials for demonstration purposes.

-

VIDEO: Recycling and machining carbon fiber scraps

Elevated Materials has partnered with Toray Composite Materials America, Inc. to collect and upcycle reclaimed carbon fiber scraps into large billet laminates, which can then be cut into various parts using CNC mills.

-

Optimizing machining for composites: Tool designs, processes and Industry 4.0 systems

Hufschmied moves beyond optimized milling and drilling tools to develop SonicShark inline quality control system and Cutting Edge World cloud platform for optimized tool use and processes.

.jpg;width=70;height=70;mode=crop)