CAMX 2021 exhibit preview: Georgia-Pacific Chemicals

Georgia-Pacific presents new technologies for reducing formaldehyde in phenolic resins and enabling applications in electric vehicles and other industries.

Georgia-Pacific Chemicals (Atlanta, Ga., U.S.) presents its extensive line of phenolic resins and corresponding technologies and services, which are used as a component in composite applications including mass transit, aerospace, oil rigs, electronics and electric vehicles (EV).

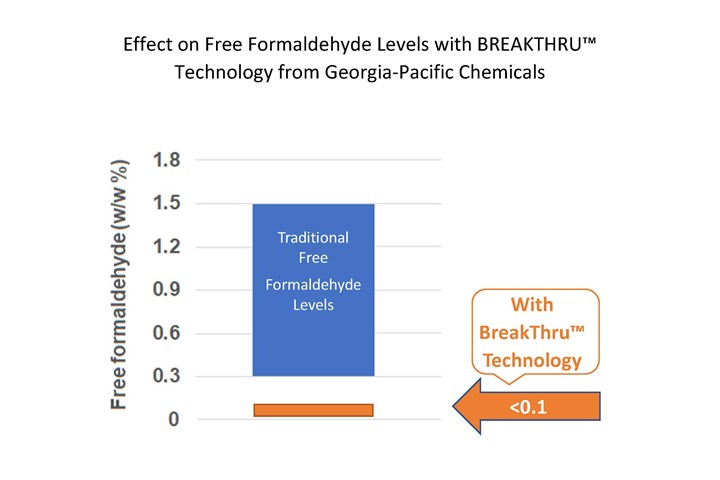

One featured product is BREAKTHRU technology, first introduced at the virtual CAMX 2020, which is said to significantly reduce residual formaldehyde content in phenolic resins to below 1,000 ppm or less than 0.1%. The technology can also reduce free phenol levels and has a faster curing profile, and may improve performance in honeycomb applications.

At CAMX 2021, Georgia-Pacific Chemicals is presenting a paper by Frank Ludvik, Ramji Srinivasan and Charles Chan titled “Emerging Trends in Phenolic Resin for Use in Composites.” The paper provides a background review of phenolic use in composites and what future advancements in phenolic resin chemistry are being explored to answer composite manufacturer needs. The paper will be available to CAMX participants after the conference until Dec. 31 in the CAMX+ virtual conference.

In addition to the technical presentation in the education track, Georgia-Pacific Chemicals is presenting its resins and technology in the CAMX Theater on Wednesday, Oct. 20 at 10 a.m.

The company says its phenolic product potfolio offers properties needed for pultrusion, sheet and bulk molding compounds (SMC/BMC), hand layup/spray-up resin transfer molding (RTM), vacuum infusion, laminating, coating, filament winding, honeycomb and glass fiber and carbon fiber prepreg applications. Depending on the application needs, phenolic resins can impart characteristics of low smoke generation, strength, low color, flexibility, fire resistance, post-formability, high temperature resistance or modulus properties. In addition, parts made from Georgia-Pacific Chemicals’ resins systems have passed United States, British and International Maritime Organization Standard Fire tests or meet Military Specification MIL-R-9299C requirements.

Related Content

-

VIDEO: Recycling and machining carbon fiber scraps

Elevated Materials has partnered with Toray Composite Materials America, Inc. to collect and upcycle reclaimed carbon fiber scraps into large billet laminates, which can then be cut into various parts using CNC mills.

-

CAMX 2023 Attendee Survey

CAMX – The Composites and Advanced Materials Expo is right around the corner, and we want to better understand your hopes and expectations heading into the show. CompositesWorld asks you to answer one of the five questions in the survey below. Responses will remain anonymous, and some may be published in the CAMX Show Daily, which is distributed at the show. The survey will take less than 5 minutes to complete.

-

High-strength, nondestructive adhesive-bonded fasteners

CAMX 2023: Rotaloc bonding fasteners come in a variety of baseplate styles, threads, sizes and materials for high-strength, nondestructive bonding with fiber-reinforced composites and thermoset/thermoformed plastics.

.jpg;width=70;height=70;mode=crop)