CAMX 2021 exhibitor preview: AGC Chemicals

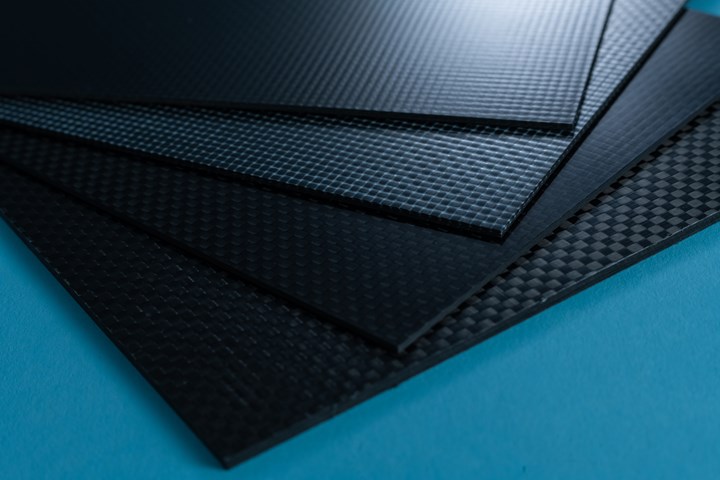

AGC Chemicals’ Fluon+ fluoropolymers are ideal for composites applications that require a durable, lightweight material, such as automobiles, aircraft and sports products.

AGC Chemicals Americas Inc. (Exton, Pa., U.S.) introduces Fluon+ functionalized fluoropolymers that reportedly enhance the performance of carbon fiber-reinforced thermoplastic (CFRP & CFRTP) composites. These compounds are ideal for composites applications that require a durable, lightweight material, such as automobiles, aircraft and sports products, as well as printed circuit boards requiring low transmission loss and high heat resistance.

AGC says the performance benefits of these compounds include:

- Wide temperature range (-200°C up to 260°C)

- Impact strength

- Vibration damping

- Near-zero water absorption

- High-temperature adhesion

- Flame retardancy

- Reduced micro-cracking

- Prevention of galvanic corrosion

- Superior chemical resistance

- Excellent dielectric properties

- Low-friction surface.

AGC’s fluoropolymer-modified polyether ether ketone (mPEEK) can be used to produce different geometries such as sheets, rods, tubes, gears, liners, wire and cable insulations and films that withstand demanding operational conditions. According to AGC, the compound improves processability via extrusion molding, injection molding and compression molding. It also demonstrates a lower dielectric constant than standard PEEK at high temperatures up to 260°C.

In addition, AGC’s fluoropolymer-modified polyphenylene sulfide (mPPS) can be used to produce films, bearings, bushings, hoses and other flexible tubing and liners for chemical processing in oil and gas. AGC says it is ideal for applications that require high-temperature (>200°C) and chemical resistance, as well as retained performance.

Related Content

-

Wireless strain measurement system for die-cast and injection molding

CAMX 2023: Gefran introduces the QE2008-W, a non-invasive, magnetically mounted strain solution with Bluetooth transmission that uses sensors to accurately measure and maintain equipment quality.

-

Graphene-enhanced SMC boosts molded component properties

CAMX 2023: Commercially sold GrapheneBlack SMC from NanoXplore increases part strength, stiffness and provides other benefits for transportation, renewable energy, energy storage and industrial markets.

-

Isobaric double belt press is well suited to continuous production

CAMX 2023: Flexible and robust double belt presses from Held Technologie are adaptable to various base composite material requirements to produce top-quality, long-lasting products.