Comprehensive composites services cover concept to completion

JEC World 2024: KraussMaffei presents its complete technology portfolio in the fields of lightweight construction and surfaces, covering a variety of end markets.

KraussMaffei provides additive manufacturing opportunities. Source (All Images) | KraussMaffei

Visitors to KraussMaffei’s (Parsdorf, Germany) booth can expect a wide range of exhibits targeting the company’s various composites technologies, from complex fiber composites/lightweight components to the future of KraussMaffei’s manufacturing processes.

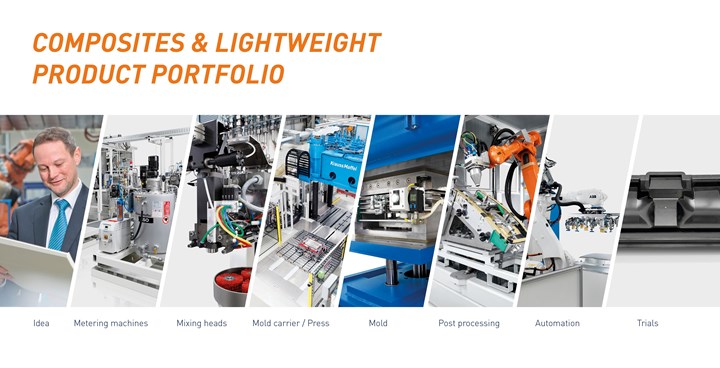

KraussMaffei offers its customers comprehensive expertise in designing and implementing complete production lines for plastic components, from planning to series production. At JEC, visitors can discover the latest trends and innovative solutions in the following sectors:

- Automotive industry, including electric vehicles (EVs)

- Commercial and agricultural vehicles

- Aerospace, including advanced air mobility (AAM)

- Building and construction

- Renewable energies

- Recycling.

In recent years, KraussMaffei says it has developed numerous technologies for the automotive industry and successfully brought them to series production readiness on the market. The focus here is on lightweight structural components — such as carbon fiber rims, leaf springs and battery enclosures for EV vehicles — which are manufactured via high-pressure resin transfer molding (HP-RTM), as well as on-design components — interior trim with backlighting and a self-healing surface — processed via KraussMaffei’s ColorForm process. The company’s novel BatteryEncapsulation technology enables it to offer battery cell protection with highly reactive and flame-retardant polyurethane (PUR).

For commercial and agricultural vehicles, the focus is on large-scale interior and exterior trim parts. The cladding of a tractor hood will be on display, which is produced using long fiber injection (LFI), more economical for small quantities than SMC, KraussMaffei points out. LFI can also be combined directly with numerous surface technologies such as thermoformed films, in-mold painting or artificial leather films.

In the aerospace sector, including AAM, KraussMaffei is working with its partner, the National Institute for Aviation Research (NIAR) at Wichita State University, and its Advanced Technologies Lab for Aerospace Systems (ATLAS), to further develop its automated and highly productive thermoplastic and thermoset fiber composite technologies in order to meet the extreme requirements in terms of weight, material selection and process stability for these end markets.

KraussMaffei considers its construction industry solutions in terms of decades, which is how long corrosion-resistant profiles and concrete reinforcements must reliably fulfill their function. With the pultrusion process (i.e., fiber-reinforced extrusion), corresponding components can be produced efficiently and reliably. At the booth, profiles for windows and other applications, as well as reinforcing rods, can be viewed.

Pultruded profiles on which solar panels can be mounted are ideal for renewable energy. These technologies come from KraussMaffei’s U.K. subsidiary Pultrex, as do the rotor blade belts used to reinforce the rotor blades of large wind turbines.

In addition, KraussMaffei is working to break new ground in recycling with its three partners Rampf, Remondis and BASF, driving forward the recycling of PUR. Insulating materials from refrigerators are returned to the material cycle on an industrial scale and converted into high-quality recycled polyol by means of chemical processing.

KraussMaffei cites its wide-ranging, comprehensive system solutions for reaction process machinery, ranging from individual metering machines to complete system concepts, including post-processing, automation and testing. The company also manufactures molds for various processing techniques — from composite molds to the backfoaming of molded parts. These customized molds are specially adapted to the respective application and ensure optimum processes. Additive manufacturing is yet another area in which KraussMaffei is exploring, not only for cost-effective, fast and uncomplicated 3D printing, but also for large-format tools and customer-specific components.

Experts from KraussMaffei are available to provide more details, or help customers find the best solutions to suit their requirements, from concept to component completion.

Visit KraussMaffei at Booth 5-N130.

Related Content

JEC announces 11 Innovation Award winners

The JEC Group has announced the winner for each of the 11 Innovation Award categories. Learn more about the winners and their projects at JEC World 2024.

Read MoreJEC World 2023 highlights: Innovative prepregs, bio-resins, automation, business development

CW’s Jeff Sloan checks in with JEC innovations from Solvay, A&P, Nikkiso, Voith, Hexcel, KraussMaffei, FILL, Web Industries, Sicomin, Bakelite Synthetics, Westlake Epoxy and Reliance Industries.

Read MoreWhat to expect at JEC World 2023: Exhibit previews

JEC World 2023 will be held April 25-27 in Paris, France. Check out CW’s exhibitor preview compilation to learn what to expect from some of this year’s exhibitors.

Read MoreFlax fiber composite innovations, circularity services

JEC World 2024: Flax fiber producer Groupe Depestele and sustainable composites company Greenboats demonstrate flax fiber materials, demonstrators and product offer Circular Structures.

Read MoreRead Next

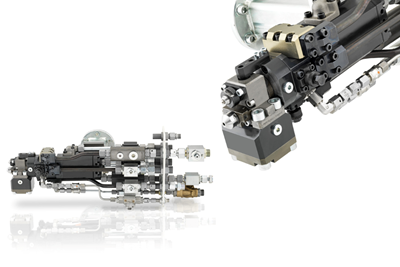

KraussMaffei optimizes SCS process with quick nozzle change module

Efficiency, resource optimization and environmental responsibility are key focuses behind the seamless switch between flat and round jet nozzles, used for spraying polyurethane onto composite components.

Read MoreKraussMaffei completes largest relocation project to Parsdorf

One of four relocation projects since 2018, the modernized site will enable the 185-year-old company to operate efficiently, digitally and sustainably.

Read MoreKraussMaffei introduces calculation tool to predict product lifecycle costs

The lifecycleValueCalculator is an example of how digitalization is supporting decarbonization for injection molding, extrusion and reaction process technologies by creating transparency about CO2 emissions.

Read More

.jpg;maxWidth=300;quality=90)