JEC announces 11 Innovation Award winners

The JEC Group has announced the winner for each of the 11 Innovation Award categories. Learn more about the winners and their projects at JEC World 2024.

Following the pre-selection of 33 finalists, JEC (Paris, France) has officially announced the 11 winners (representing each category) for this year’s JEC Composites Innovation Awards. Chosen by an international jury, the awards ceremony took place Feb. 8, 2024.

CFRP lattice satellite central tube

ATG Europe has developed a one-shot manufacturing process for uninterrupted prepreg fiber-placed lattice structures that aim to replace current satellite central tube designs. These cylindrical lattice structures offer optimal structural functionality at a reduced mass. This innovation included the design, development and manufacture of a fully representative carbon fiber-reinforced polymer (CFRP) lattice central tube based on requirements for ESA’s Plato satellite.

Companies: ATG Europe (Netherlands) and partner ÉireComposites Teo (Ireland)

EmpowerAX — Additive functionalization

The EmpowerAX demo part is a multi-curved thermoset shell additively functionalized with short- and continuous fiber-reinforced elements realized by DLR and 12 EmpowerAX members. It demonstrates the industrially available process chain for additive functionalization.

Companies: German Aerospace Center (DLR, Germany), with partners 9T Labs AG (Switzerland), Airtech Europe (Luxembourg), Ansys Switzerland GmbH (Switzerland), CEAD B.V. (Netherlands), Ensinger GmbH (Germany), Fiberthree GmbH (Germany), FILL Gesellschaft m.b.H. (Austria), Hans Weber Maschinenfabrik GmbH (WEBER additive, Germany); Prime Aerostructures GmbH (Austria), Siemens AG (Germany), Suprem SA (Switzerland) and SWMS Systemtechnik Ingenieurgesellschaft GmbH (Germany)

Monolithic CFRP-aluminum monocoque: A novel approach for carbon neutrality

Source | Toyota Motor Corp.

A full-scale, variable-axial, CFRP-aluminum semi-monocoque prototype was designed, fabricated and evaluated. It was developed to demonstrate the potential of improving weight reduction in large 3D structures with complex topology and carbon neutrality through the effective use of CFRP. It shows a 15% weight reduction with minimal fiber waste (4%) and assembly cost.

Companies: Toyota Motor Corp. (Japan) and partners Toyota Central R&D Labs. Inc (Japan), Toyota Customizing & Development Co. Ltd. (Japan) and TISM Co. Ltd. (Japan)

Reactive PA6 pultrusion: Boost for TP composites

Reactive thermoplastic pultrusion enables the production of cost-effective and highly resilient automotive components. The profiles are integrated in the final part by injection or compression molding. The PA6-based composites enable simple recycling without dismantling.

Companies: Röchling Automotive SE (Germany) with partners Fraunhofer Institute for Chemical Technology ICT (Germany) and Röchling Industrial SE & Co. KG – Haren (Germany)

Renco MCFR (mineral composite fiber reinforced)

Renco MCFR is a state-of-the-art structural building system comprised of interlocking composite building units of various types and sizes of blocks, columns, beams, joists, headers, decking, connectors, etc. These products are all adhesively joined (chemically bonded) to form monolithic structures. Renco products are manufactured with naturally occurring raw materials and newly composed materials from recycled products in an environmentally friendly manufacturing process.

Companies: Renco USA (U.S.) with partners Arquitectonica (U.S.), Catalyst Communications (U.S.), Coastal Construction (U.S.), DeSimone Consulting Engineers (U.S.) and DeVit Consulting Inc. (U.S.)

EMPHASIZING to enhance material property by sizing

EMPHASIZING aims to create a new advanced material, “glassene,” with prices close to glass fiber, performance to rival some carbon fiber and a very low lifecycle analysis (LCA). Fiberglass from a range of sources (wind, marine, fiber production) is reclaimed as 100% clean glass by the DEECOM pressolysis process. The fibers are chopped into 6-millimeter lengths before a range of sizing chemistries are considered, assessed and tested. Then they are compounded with polyamide thermoset resin and injection molded.

Companies: B&M Longworth (Edgworth) Ltd. (U.K.) with partners Autotech Engineering, Brunel University London (U.K.), EMS-Grivory (U.K.), Ford Motor Co. (U.K.), Gen2Plank Ltd. (U.K.) and TWI Ltd. (U.K.)

Wind turbine blade executable digital twin

The wind turbine blade executable digital twin combines a reduced-order model with live sensor signal to assess structural performance in real time. Physical and virtual sensors combined is key to perform structural health monitoring (SHM).

Companies: ReliaBlade (Denmark) with partners Ceko Sensors (Denmark), Force Technology (Denmark), Siemens Industry Software (SISW, Belgium), Technical University of Denmark (Denmark) and Zebicon (Denmark)

Maximum mass reduction of cutting tools

A new modular cutting tool for a woodworking machine has been developed, exploiting the mechanical advantages of CFRP. Design principles resulted in a tool design with triangular components that absorb centrifugal forces, and an outer shell that accommodates bending and torsional loads. More than 50% weight reduction and an increase in working speed of more than 50% has been achieved.

Companies: Deutsche Institute für Textil- und Faserforschung Denkendorf (DITF, Germany) with partner Leitz GmbH & Co. KG (Germany)

OceanWings

OceanWings is a patented, automated, self-raising and lowering vertical wingsail system made of composites that enables newbuild or existing ships to reduce their fuel consumption and resulting carbon footprint by up to 50%. The technology enables the wing’s ability to withstand winds of up to 100 knots, while ensuring the proper functioning of its operations: automatic orientation in relation to the wind, adjustable camber, reefable and furlable.

Companies: AYRO (France) with partners Alizés (France), Jifmar Offshore Services (France), Zéphyr et Borée (France), Neptune Marine (Pays-Bas), VPLP Design (France) and ArianeGroup (France)

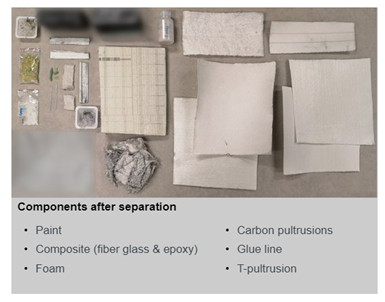

Blade circularity solution

Source | Vestas Wind Systems

CETEC’s blade circularity solution renders epoxy-based turbine blades circular without altering the material’s design or composition. It employs a chemical process, breaking down epoxy resin into virgin-grade materials, and precisely separating glass, carbon fibers, core material and metal components, establishing a circular economy for blade manufacturing.

Companies: Vestas Wind Systems A/S (Denmark) with partners Vestas (Denmark), Olin (Germany), Aarhus University (Denmark), Danish Technological Institute (Denmark) and Stena Recycling (Denmark and Sweden)

Photo Credit: Vestas Wind Systems

Green snowboard with A.L.D.-tech.

A snowboard with patented anisotropic coupling effect (A.L.D.-tech.) was made out of hemp and recycled carbon fibers (rCF) with bio-based epoxy resin. Thanks to the material properties of the hemp tape and the directional rCF nonwovens, both materials can be processed automatically using DFP. This saves 75% of cutting waste of the hemp fibers, saving cost and reducing the CO2 footprint.

Companies: silbaerg GmbH (Germany) with partners Sächsisches Textilforschungsinstitut e.V. (STFI, Germany), bto-epoxy GmbH (Austria), Circular MTC e.V. (Germany) and SachsenLeinen GmbH (Germany).

Related Content

Flax fiber composite innovations, circularity services

JEC World 2024: Flax fiber producer Groupe Depestele and sustainable composites company Greenboats demonstrate flax fiber materials, demonstrators and product offer Circular Structures.

Read MoreJEC World 2024 highlights: Thermoplastic composites, CMC and novel processes

CW senior technical editor Ginger Gardiner discusses some of the developments and demonstrators shown at the industry’s largest composites exhibition and conference.

Read MoreJEC World 2023 preview

JEC World is the composites industry’s largest trade event, featuring exhibits, presentations and specialized pavilions covering the entire composites industry supply chain.

Read MoreInnovation Award finalists revealed for JEC World 2024

Returning to the international composites trade show are the Innovation Awards, representing up to 33 finalists in 11 categories that highlight composites innovation excellence and fruitful collaborations.

Read MoreRead Next

Top 20 JEC Startup Booster 2024 finalists are revealed

Tailored to find and assess the best startups in the composite industry, the 20 Booster competition finalists will be pitching their projects on stage March 5-7 at JEC World 2024.

Read MoreSAMPE nomination awards are open until Feb. 15th

Industry has the opportunity to honor individuals or chapters that have demonstrated excellence, commitment and innovation to the composites community.

Read MoreJEC Composites Innovation Award 2023 winners

The JEC Group has announced the winner for each of the ten Innovation Award categories. Learn more about the winners, their projects and future expectations in person or via livestreaming at JEC World 2023.

Read More