CT data drives new level of fiber analysis

Volume Graphics (VG, Charlotte, N.C., U.S.) has launched the latest version of its software solution for rendering data derived from computed tomography (CT) scanning operations.

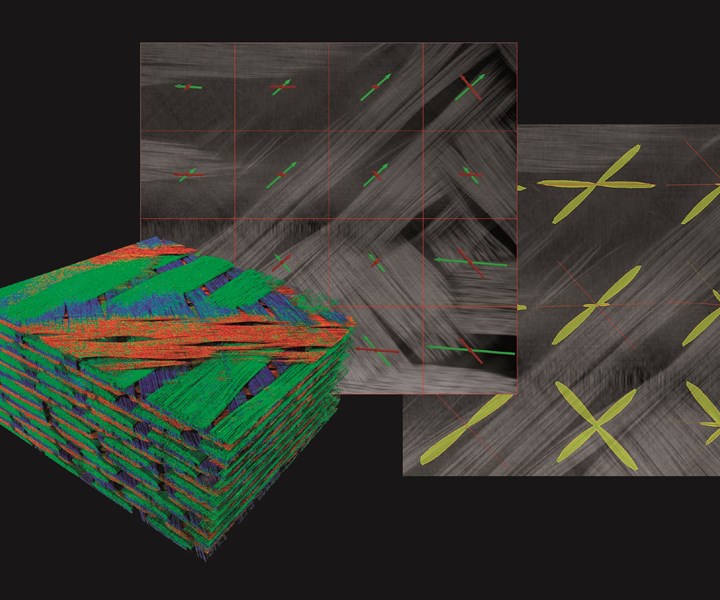

Volume Graphics’ suite of software converts computed tomography (CT) into 3D images to provide analysis of fiber orientation and quality. Source | Volume Graphics

Volume Graphics (VG, Charlotte, N.C., U.S.) has launched the latest version of its software solution for rendering and analyzing data derived from computed tomography (CT) scanning operations. The suite of software includes VGSTUDIO, VGSTUDIO MAX, VGMETROLOGY, VGinLINE and myVGL. At its most basic level, VG’s software is designed to receive CT data from inline or discrete scanning systems and then build 3D projections of the composite part from multiple angles. These projections include not just a shell, but interior structures as well, down to the fiber level, thereby revealing inclusion, porosity, cracks, delamination and other flaws. The software also can compare actual dimensions to nominal CAD dimensions, including wall thickness analyses.

VG says CT technology is typically (but not exclusively) used on smaller parts (size of a pinhead to the size of a smartphone), with VG’s software providing imagery of specific fiber placement or overall fiber orientation. The resolution/granularity of the VG software’s images depends on how close the CT detector is to the part being scanned; the closer the detector is, the better the voxel resolution is. The software’s speed of analysis depends on the computing hardware on which it operates and the size of the CT dataset it is reading. In general, say VG representatives, image and analysis are completed within minutes of CT data delivery.

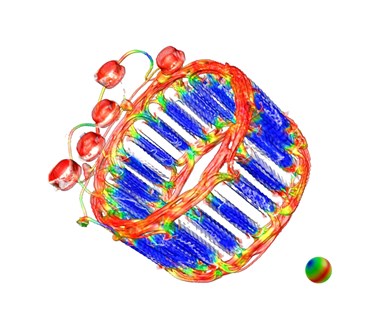

VG’s software can render and analyze CT data from composites reinforced with fibers of all types, including carbon fibers, glass fibers, aramid fibers and natural fibers. The software is also compatible with ceramic matrix composites (CMC) and fiber-reinforced concrete.

Related Content

-

Carbon fiber, bionic design achieve peak performance in race-ready production vehicle

Porsche worked with Action Composites to design and manufacture an innovative carbon fiber safety cage option to lightweight one of its series race vehicles, built in a one-shot compression molding process.

-

Active core molding: A new way to make composite parts

Koridion expandable material is combined with induction-heated molds to make high-quality, complex-shaped parts in minutes with 40% less material and 90% less energy, unlocking new possibilities in design and production.

-

Optimizing a thermoplastic composite helicopter door hinge

9T Labs used Additive Fusion Technology to iterate CFRTP designs, fully exploit continuous fiber printing and outperform stainless steel and black metal designs in failure load and weight.