Dieffenbacher highlights Fibercut system for increased productivity

Dieffenbacher’s fully automated cutting and stacking system enables automated SMC processing applications.

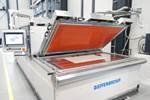

A Dieffenbacher Fibercut cutting unit with cutting belt. Photo Credit: Dieffenbacher

Automotive suppliers and others who manufacture composite parts can increase production as much as 7% with Dieffenbacher’s (Eppingen, Germany) fully automated Fibercut cutting and stacking system featuring a quick-change unit. The Fibercut system enables automated processing of sheet molding compound (SMC) materials. While many SMC applications use error-prone and time-consuming manual processes, Dieffenbacher’s fully automated Fibercut SMC cutting and stacking system provides increased productivity and plant efficiency.

Fibercut consists of a cutting unit with a cutting belt, a stacking table and a quick-change unit for SMC on coil or in festoons to further increase productivity. The cutting unit communicates with the stacking gantry or robot and is able to implement complex laying patterns automatically.

“Different cutting patterns can be realized at the same time with maximum flexibility,” says Marco Hahn, director sales of the forming business unit at Dieffenbacher. “Using an active compensation cut, deviations in the weight of the material stack will be actively corrected. This ensures compliance with weight tolerances and maximum reproducibility even with the geometric complexity of the SMC layer structure.”

The quick-change unit increases the system’s availability by enabling a complete SMC coil or festoon changeover within a few minutes. Including gripper change stations, the production line can be rapidly switched over to another component. Additionally, the Fibercut monitors when the SMC material nears its end and notifies the operator. The operator can prepare to change the material without an unplanned stop of the machine. The quick-change unit is equipped with an automated foil removal system to reduce the “on-air time” of the SMC to preserve the styrene for optimal part quality.

Because the material can be prepared offline and the material change process runs fully automatically, the quick-change unit can save 10-15 minutes per change. Assuming annual production of 80,000 pieces, SMC consumption of 2 million lbs per year and 600 related coil changes, output can be increased by 3,000-4,500 parts or 3-5% per year.

“Utilizing SMC festoons, the annual output of the production line can be increased even more,” Hahn says. “As festoons usually contain less SMC material than coils, more changes are needed to achieve the same output per year. The quick-change unit ‘converts’ change time into additional production time, enabling an increase in output of up to 5-7%.”

After the SMC material is unwound from the coil or conveyed out of a festoon automatically, it is cut to size as required by engaging longitudinal knives and a cross-cutting knife. The position of the longitudinal knives can be adjusted manually for creating different cutting patterns. The material feed takes place by means of a driven mangle roll system. Consistent tension on the material, as well as changes in the coil diameter, are compensated for by the interaction of a dancer roll system with a controlled roll unwind drive, which promotes uniform material in-feed.

The SMC edge trimming removes the dry edges of the SMC material for better part quality and a reduced scrap rate. During cross-cutting, the roller knife is lightly pressed against a “shear block.” This promotes the most precise cuts and provides a scissor cutting process. It also enables precise compensation cuts.

“To reduce maintenance costs, all knives are designed as roller knives,” Hahn says. “All longitudinal knives operate ‘contactless,’ meaning they run in grooves and have contact only with the material. This increases the service life of the equipment and reduces operating costs.” For maximum flexibility, the Fibercut can be equipped with a customized number of roller knives. During production, the knives can be switched on and off individually to create different cutting patterns.

From the cutting conveyor, the SMC cuts are stacked on a separate stacking table with weighing cells by using a handling robot or gantry to create an individually configurable SMC stack. Inline weight measurement of each cut and the corresponding length correction of the subsequent cut actively compensate for any weight fluctuations in the material, providing an accurate total weight of the final SMC stack.

A robot then picks up the complete SMC stack off the stacking table and places it into the mold of the press using a corresponding gripper. The improved stack weight results in better material flow and cavity filling, which reduces the overall scrape rate. In addition, the Fibercut pre-stacks SMC layers, simplifying the stacking process. As a result, there is a reduction in cycle time and an increase in productivity.

The Fibercut has a clear visualization to monitor the material in-feed for improved changeover times as well as the stacking process of the SMC batch to control the weights of the cuts or the final SMC stack. The recipe menu helps to keep track of existing projects or parts and saves the cutting patterns. Operators get a quick, clear overview of the status of the machine at all times. Text messages and a notification archive assist with troubleshooting.

The Fibercut can be used in a fully or semi-automated production cell and, in an alternative design, a manual production setup. In a fully automated production cell, SMC stacking is performed by a stacking robot or gantry. Dieffenbacher offers line integration, programming and gripper systems. For use in a manual production setup or semi-automated production cell, the Fibercut is equipped with safety features that enable safe human interaction. Additionally, the Fibercut is available as a “transportable system” that can be used flexibly in different production areas within a building. The footprint of Fibercut is approximately 6,300 mm × 2,800 mm. The cutting belt and stacking table are customizable.

Related Content

Johns Manville launches multi-end roving MultiStar 272

Multi-end fiberglass roving serves as a reliable product for SMC compounders aiming to excel in automotive applications.

Read MoreSMC composites progress BinC solar electric vehicles

In an interview with one of Aptera’s co-founders, CW sheds light on the inspiration behind the crowd-funded solar electric vehicle, its body in carbon (BinC) and how composite materials are playing a role in its design.

Read MoreImproving carbon fiber SMC simulation for aerospace parts

Simutence and Engenuity demonstrate a virtual process chain enabling evaluation of process-induced fiber orientations for improved structural simulation and failure load prediction of a composite wing rib.

Read MorePly stacking, cutting process optimized via automation, smaller footprint

CAMX 2024: Schmidt & Heinzmann customers are able to produce SMC or dry fiber fabric stacks more efficiently thanks to the AutoCut Pick&Place system.

Read MoreRead Next

New Flex option introduced for Dieffenbacher Fibercon consolidation system

Fibercon Flex version equips the upper frame with a flexible sheet that enables consolidation independent of tape layup geometry and thickness.

Read MoreDieffenbacher TailoredPress promotes 70% energy savings

Variable-speed pump drives minimize unnecessary energy consumption during metal and composites forming operations.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More