Dieffenbacher North America Inc.

The Dieffenbacher Group

9495 Twin Oaks Dr.

Windsor, ON N8N 5B8 CA

519-979-6937

dna@dieffenbacher.ca

dna-manufacturing.com

About Dieffenbacher North America Inc.

IS THIS YOUR COMPANY?

As Seen On CompositesWorld

Dieffenbacher North America Inc. Supplies the Following Products

- Extruders

- LFRT compounding/molding machinery

- Preform manufacturing equipment

- Presses, compression molding

- Presses, hydraulic

- Presses, laminating

- Presses, low-pressure

- Presses, software and controls

- Repair services, equipment and machines

- Resin transfer molding equipment (RTM)

Editorial, News, and Products

-

Rein4ced, Dieffenbacher automate large-scale production of CFRP bike frames

A synergistic alliance combining Dieffenbacher’s production automation with Rein4ced’s hybrid Feather composite led to fully automated bike frame production line, which will be expanded to other composite products.

-

Dieffenbacher highlights Fibercut system for increased productivity

Dieffenbacher’s fully automated cutting and stacking system enables automated SMC processing applications.

-

Intelligent mobility concepts support e-mobility

CAMX 2023: Materials, process and automation solutions from Dieffenbacher enable Industry 4.0, high output, optimized quality and reproducible composites manufacturing.

-

Dieffenbacher TailoredPress promotes 70% energy savings

Variable-speed pump drives minimize unnecessary energy consumption during metal and composites forming operations.

-

JEC World 2023 preview

JEC World is the composites industry’s largest trade event, featuring exhibits, presentations and specialized pavilions covering the entire composites industry supply chain.

-

Plant tour: Victrex Composites Solutions, Bristol, Rhode Island, U.S.

De-risking thermoplastic composites at industrial scale via hybrid overmolding.

-

Dieffenbacher highlights the short-stroke press for energy-efficient production

Short-stroke closing system and adaptive accumulator management features are designed for minimum energy consumption, high press forces and short cycle times when producing high-quality composite components.

-

Dieffenbacher automates SMC lines for enhanced productivity and efficiency

Quick-change cutting system reduces changeover times to six to seven minutes, and ensures maximum reproducibility, even with the complex geometries.

-

Continental Structural Plastics orders new Dieffenbacher D-LFT line

D-LFT line, including a 2,500-tonne hydraulic press, will be used to produce pickup truck tailgate covers at the Teijin Group subsidiary’s Sarepta, Louisiana facility.

-

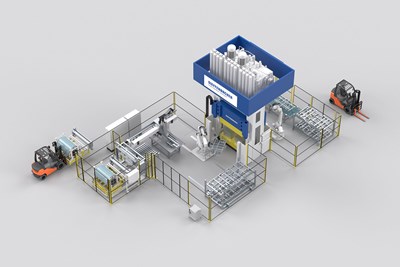

Dieffenbacher D-LFT line enables large thermoplastic component production

The high-capacity direct-long-fiber thermoplastic (D-LFT) molding line has been further modified into a one-stage extrusion process, and produces 100% recycled thermoplastic components.

-

Dieffenbacher innovations focus on SMC, D-LFT

Dieffenbacher is presenting its solutions for tape laying, SMCs, D-LFT and wet molding technologies, as well as a new messaging and ticket system app.

-

Overmolded hybrid parts open new composites markets

A process that combines continuous carbon fiber-reinforced PAEK with chopped fiber/PEEK overmolding is making inroads in the aerospace market. Parts that previously could not be produced cost-effectively from composites can now be made at less cost than their metal counterparts.

-

Dieffenbacher, Arburg partner to offer combined injection/transfer molding process

The companies demonstrated their combined capabilities with a recent project to develop a modular injection/transfer molding cell to produce hybrid parts.

-

Compression presses keep evolving in response to composites innovation

Shorter, lighter, smaller footprint Fiberpress machines are ideal for facilities with lower ceilings, automated production lines.

-

CarbonPro box: new forming process

From materials to assembly, the carbon fiber composite CarbonPro box manufacturing process features innovative, automated preforming technologies.

-

Continuous tapes, D-LFT meet up in new compression molding process

Design research for an automotive load floor module drove development of a new compression molding process for direct-long-fiber thermoplastic (D-LFT) composites.

-

AVK presents its 2018 Innovation Awards

The 2018 AVK Innovation Awards were presented at the International Composites Congress (ICC) on Nov 5, chosen from more than 50 submissions.

-

Consolidating thermoplastic composite aerostructures in place, Part 1

After more than 30 years of development, in-situ consolidation is nearing its promise to eliminate fasteners and the autoclave, and enable an integrated, multifunctional airframe.

-

Fraunhofer ICT in-mold pressure sensors for HP-RTM

Pressure sensor-based mold fill expected to maximize part consistency and minimize cycle time for auto industry molders.

-

Plant Tour: Fraunhofer ICT, Pfinztal, Germany

This wide-ranging research center works with government and industry to develop the best of polymer composite processing, across a range of technologies.

-

A look inside Fraunhofer ICT

Fraunhofer-Gesellschaft (Munich, Germany) is the largest applied research organization in Europe, with more than 67 institutes and research units located throughout Germany staffed by 24,500 people, mostly scientists and engineers. CW recently got a chance to tour one, Fraunhofer ICT in Pfintzal, Germany.

-

SMC: Old dog, more tricks

In the sheet molding compound renaissance, the advent of new resins and compounds are broadening the definition and application of this versatile family of composites.

-

Preforming goes industrial: Part 1

ATL and AFP-based preforming options now abound for processing dry and/or impregnated reinforcements as quickly as 1 minute or less with potential yearly part yields in the millions.

-

Automated Preforming, Part 1: Numbers and Landscape

CW’s multi-blog series on preforming begins with an overview and quick look at the numbers: 1-minute take time, 10-15 seconds per layer, 490-kg/hr and 3.5 million parts/year. Are you ready for serial CFRP production?

-

500,000 parts per year? No problem!

BENTELER-SGL develops fully automated HP-RTM production of the weight- and space-saving composite leaf spring for Volvo’s multi-model SPA global platform.

-

Compression molding: New materials and markets

From multifunctional aircraft interiors to compounds using continuous fabrics to the growing use of recycled carbon fiber – compression molding offers new opportunities.

-

JEC World 2017 exhibit preview

JEC World will be held March 14-16 in Paris. CW previews some of the products and technologies that will be at the show.

-

Small companies, long-term impact

In a time known for owner “exit strategies,” longevity in family-owned composites businesses is heartening.

-

BMW 7 Series Plant: Dingolfing, Germany

Via four different manufacturing methods, CFRP goes mainstream in automated multi-material BIW and assembly operations at BMW’s busiest plant.

-

LG Hausys invests in HP-RTM machine from KraussMaffei

The machine is producing advanced structural components for the visible part of automobiles, including a CFRP roof panel.

-

Wet compression molding

Automated process cuts cycle time and cost for CFRP parts with potential for 65% fiber volume via Dynamic Fluid Compression Molding variant.

-

Turnkey manufacturing systems: Simplifying automated HP-RTM

Having offered turnkey systems for composites since the 1990s for sheet molding compound (SMC), long fiber thermoplastic (LFT) and glass mat thermoplastic (GMT), Dieffenbacher (Eppingen, Germany) now has automated systems for high-pressure resin transfer molding (HP-RTM).

-

Turnkey manufacturing systems: Materials, markets and maturation

Automated production cells promise affordability and less risk in scaling up composites production, but are they really the path forward?

-

Thermoplastic composites “clip” time, labor on small but crucial parts

Preconsolidated carbon fiber/PPS and PEEK and automated thermoforming enable six-figure production of connectors for the Airbus A350 XWB.

-

CAMISMA’s car seat back: Hybrid composite for high volume

Recycled fibers, in-situ polymerized PA12 and steel inserts combined in one-shot process to cut weight 40 percent at competitive cost, cycle time and safety.

-

2014 JEC Europe Review

The composites world met again in Paris, vibrant, stronger, and more forward-looking than ever before.

-

JEC Europe 2014 Review

The composites world met again in Paris, vibrant, stronger, and more forward-looking than ever before.

-

Business and busy-ness

CT editor-in-chief Jeff Sloan returns for JEC Europe 2014 in Paris with observations about several intriguing composites industry trends.

-

Structural preform technologies emerge from the shadows

Not yet in full production, with one exception, all are aimed at accelerating composite part manufacture at fast automotive rates.

-

JEC 2013 at first blush

CT Editor-in-chief Jeff Sloan risks some immediate reactions to his week in Paris at the JEC Europe 2013 composites trade show.

-

Market Outlook: Surplus in carbon fiber's future?

Participants at CW’s Carbon Fiber 2012 Conference see one coming as early as 2016.

-

Waiting for $5/lb carbon fiber?

HPC editor-in-chief Jeff Sloan suggests we say goodbye to $5/lb carbon fiber and expect that composites will earn their way onto autos by saving drivers money.

-

Auto composites quest: One-minute cycle time?

Faced with high fuel prices and ever-more stringent restrictions on tailpipe emissions, automakers are taking composites into their own hands.

-

Formulation flexibility: Direct-SMC

Consortium applies inline-compounding technology to reinvent sheet molding compound.

-

CF 2011: Comment on end-markets and initiatives

Six speakers at the Carbon Fiber 2011 conference (December 2011) report on their organizations' activities in the carbon fiber market.

-

SPE ACCE 2011: Growing again

The Society of Plastics Engineers’ 11th conference on automotive composites fields a top slate of speakers and attracts its largest crowd.

-

UBSs: Coming to North America

Common in Europe and Asia, the composite underbody shield might finally catch on in the U.S. and Canada.

-

SPE's ACCE 2009 Show Preview

The Society’s 2009 Automotive Composites Conference & Exhibition charts an industry at a crossroads.

-

NAIA 2009 show highlights

The Detroit auto exhibition’s hybrid and electric vehicle introductions underscore the need for lightweighting with low investment cost, which composites can provide.

-

What's new in automotive front-end modules?

Composite and hybrid composite/metal solutions reduce cost and weight and increase assembly efficiency on passenger vehicles.

-

Reinforced Thermoplastics: LFRT/GMT Roundup

Recent advancements in these reinforced thermoplastic technologies are expanding their performance, enabling new applications.

-

Reinforced Thermoplastics: LFRT vs. GMT

As the suppliers of long fiber-reinforced thermoplastics and glass-mat thermoplastics battle for market supremacy, the winner is … the composites OEM.

-

Inside Manufacturing: Integrated LFRT Processing System Adds Flexibility, Cuts Costs

Advances in equipment, control and materials extend the performance range of direct, in-line compounding/molding of long fiber-reinforced thermoplastics.

-

Compression molding press technology adapts to meet new composite material processing requirements

Faster compression molding presses keep pace with new highly loaded, low-flow thermoplastics and thermosets.

-

Thermoplastic Composites Making An Impact

Product/process developments accelerate use of long-fiber-reinforced thermoplastics in automotive and industrial markets.