End-to-end solutions for increasing productivity

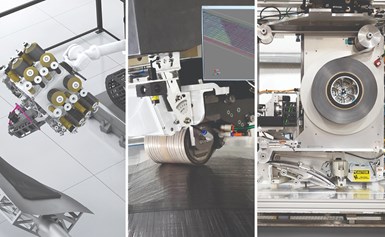

CAMX 2023: Fives is displaying its end-to-end composite manufacturing solutions for attendees, including lamination, forming and inspection technologies.

Photo Credit: Fives

Fives (Hebron, Ken., U.S.) provides end-to-end solutions for composites manufacturing, covering processes from lamination to demolding. The company offers tailored solutions for lamination, forming, inspection and curing. Its focus is on precision and efficiency to minimize waste and promote quality. Fives says it specializes in developing highly automated end-to-end solutions that increase productivity throughout the entire process.

Comprised of legacy names Cincinnati, Forest-Liné and Lund, Fives is said to hold the world’s largest install base of tape lamination and fiber placement machines. Fives offers both standard and customizable composite equipment and automated solutions based on customer needs. Some technologies used in these solutions are the Cincinnati Robotic Viper, Cincinnati Supercharger and in-process inspection (IPI) technology.

Cincinnati Robotic Viper is an automated fiber placement (AFP) machine known for its versatility and large install base. It is designed for various machine configurations, capable of accommodating different shape and size applications including concave and convex shapes. It targets OEM/Tier 1 capabilities, automates hand layup parts and offers in-process inspection. It also interfaces with ACES composites programming package. In addition, the Cincinnati Robotic Viper comes with a dockable head for flexbility.

Fives says the Cincinnati SuperCharger represents the future of automated tape lamination (ATL) machines. It features on-head scrap management, high-speed cutting on the fly, configurable platforms and the ability to handle contours and high lay-up rates.

The IPI technology integrates seamlessly into AFP machines and uses optical coherence tomography imaging to measure defects and tow placement in real time, making it suitable for various composite applications.

Related Content

-

Graphene-enhanced SMC boosts molded component properties

CAMX 2023: Commercially sold GrapheneBlack SMC from NanoXplore increases part strength, stiffness and provides other benefits for transportation, renewable energy, energy storage and industrial markets.

-

VIDEO: Recycling and machining carbon fiber scraps

Elevated Materials has partnered with Toray Composite Materials America, Inc. to collect and upcycle reclaimed carbon fiber scraps into large billet laminates, which can then be cut into various parts using CNC mills.

-

VIDEO: High-rate composites production for aerospace

Westlake Epoxy’s process on display at CAMX 2024 reduces cycle time from hours to just 15 minutes.