GEHR presents compostable, recyclable wood-based 3D printing filament

Eco-Fil-A-Gehr consists of recycled wood fibers mixed with biodegradable biopolymers, giving printed objects natural look and feel with dimensional stability and high elastic properties.

Share

GEHR (Mannheim, Germany) a producer of thermoplastic semi-finished products globally, introduces Eco-Fil-A-Gehr, a novel wood-based filament designed for professional 3D printing with high dimensional stability and optimal elastic properties, as well as compostable and recyclable capabilities.

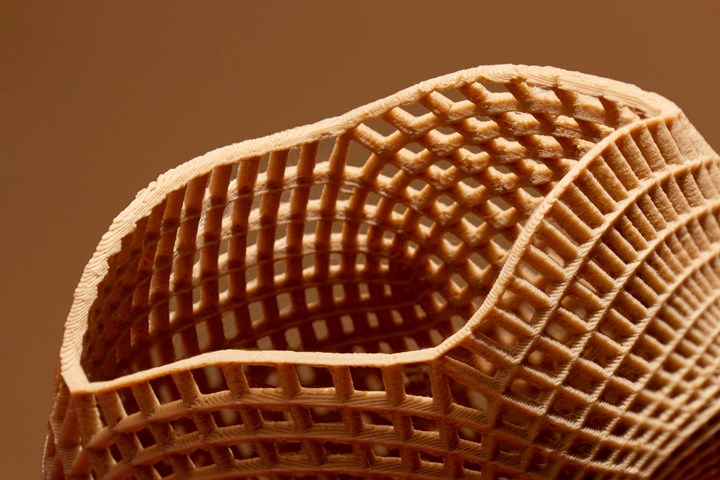

Eco-Fil-A-Gehr Wood made of Sulapac (Helsinki, Finland) consists of recycled wood fibers mixed with biodegradable biopolymers. The premium eco-filament reportedly gives the printed objects a natural look and feel and a haptic touch. It can be used to print very robust and stable parts as well as light, highly detailed objects.

GEHR has a broad portfolio of 3D filaments in a range of different materials developed for various customer needs. Sulapac’s solution for 3D printing, a material from its Sulapac Flow family, is the most recent addition to GEHR’s eco-line because of its scientifically verified sustainability features. The material used in the Eco-Fil-A-Gehr filament is industrially compostable according to BPI (ASTM D6400), contains 72% USDA certified bio-based content and leaves no permanent microplastic or toxic load behind. Furthermore, the material complies with the EU and U.S. FDA requirements for food contact materials.

The mechanical recyclability has been demonstrated by an independent third party, GEHR told CW — the material can be recycled up to six times. It has also been shown that the material can be recycled through hydrolysis back to monomers, suitable as feedstock for recycled biopolymers.

Field tests have also verified that Sulapac materials can be collected and sorted out of a mixed waste stream. When collected together, Sulapac materials do not interfere with the current mechanical recycling of conventional fossil-based or bio-based non-biodegradable plastics. GEHR notes that the technology for chemical recycling of bio-based and biodegradable materials exists, but the infrastructure is still under development.

Eco-Fil-A-Gehr is said to have a beautiful, natural appearance and a pleasant subtle odor coming from the natural wood it contains. The material has high dimensional stability and high elastic properties for 3D printing and filament extrusion. “The stability of the material is exceptional, and it works as well as or even better than other wood filaments or PLA,” says Joona Kontinen, Sulapac’s innovation manager, who has been developing the Sulapac Flow material family for various applications.

When producing the filament, a deviation of 0.05 mm in width is typically allowed. With Sulapac the deviation is less than a tenth of that, ensuring smooth production and stable quality. “The Sulapac material used in the Eco-Fil-A-Gehr Wood has the perfect combination of properties for 3D printing with no compromises in sustainability,” adds Kontinen.

First customer will likely be the cosmetic brands already familiar with Sulapac materials that are interested in the material for prototyping. Other typical applications GEHR anticipates include decorative components and point-of-sale displays. Eco-Fil-A-Gehr Wood is available to businesses and private customers through GEHR’s online store.

Related Content

-

Watch: A practical view of sustainability in composites product development

Markus Beer of Forward Engineering addresses definitions of sustainability, how to approach sustainability goals, the role of life cycle analysis (LCA) and social, environmental and governmental driving forces. Watch his “CW Tech Days: Sustainability” presentation.

-

Microwave heating for more sustainable carbon fiber

Skeptics say it won’t work — Osaka-based Microwave Chemical Co. says it already has — and continues to advance its simulation-based technology to slash energy use and emissions in manufacturing.

-

CirculinQ: Glass fiber, recycled plastic turn paving into climate solutions

Durable, modular paving system from recycled composite filters, collects, infiltrates stormwater to reduce flooding and recharge local aquifers.