Hexagon Caesar III software supports hydrogen pipeline analysis, standards

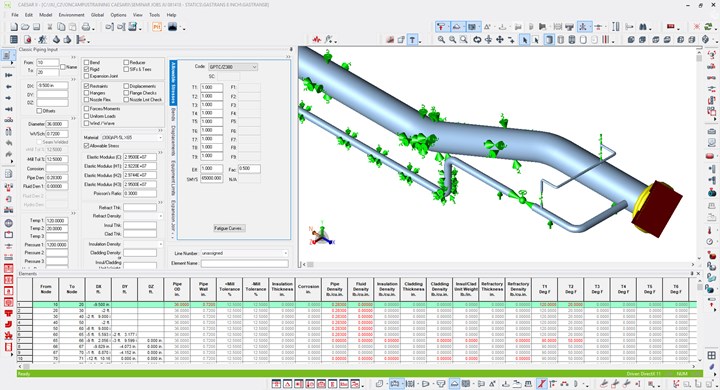

Version 14 of the stress analysis software — applicable for use with FRP pipes — enables engineers to perform analyses more accurately, following the latest developments in hydrogen codes and standards.

Hexagon’s Asset Lifecycle Intelligence division (Hoofddorp, Netherlands) announces Caesar II version 14, the latest iteration of the company’s widely used pipe flexibility and stress analysis software.

Caesar II is a complete solution that enables quick and accurate analysis of piping systems — including fiber-reinforced polymer (FRP) pipes — subjected to a wide range of loads, considering weight, pressure, thermal, seismic, and other static and dynamic conditions. In addition, it provides capabilities to analyze FRP composite pipe systems according to various standards — British standards BS 7159 and UKOOA, along with the international ISO 14692 standard are all available with Caesar II.

The software can perform analysis for all types of piping stress calculations in several environments such as buried, on ground and submerged in water. It is used in a variety of industries such as oil and gas, chemical, power, nuclear, aerospace and more, by clients that range from one-person engineering shops to large enterprise engineering environments.

A key addition of this new release is the support for hydrogen piping and pipelines with the inclusion of code ASME B31.12. Amid rapid growth in hydrogen production worldwide, this inclusion aims to ensure that engineers can take on hydrogen projects with confidence.

Other enhancements include:

- The possibility to manage wind and seismic conditions with ease using ASCE 7-2022 and IBC-2021 editions.

- The update of popular European code EN 13480-3:2017/A5:2022 , “Metallic industrial piping – Part 3: Design and calculation.”

- Enhancements for the 2022 editions of ASME B31.1, B31.3, B31.4, B31.5 and B31.8.

This version supports more than 50 international piping codes and calculational variants. It is suitable for use in the nuclear industry and includes codes ASME NC, ASME ND, RCC-M C and D for nuclear installations and complies with ASME NQA-1 quality assurance (QA).

“As projects become bigger and more complex, the potential for error rises,” Chris Bradshaw, senior product owner for Caesar II, says. “Caesar II has been trusted by engineers for more than 30 years to ensure that piping assets are not only designed and operating in compliance with the latest codes, but also that they are designed safely and with refinements. It results in greater safety, lower costs, time saved and fewer materials used.”

Related Content

-

ECOHYDRO project to enable recyclable composites for hydrogen storage

With the involvement of two schools from the Institut Mines-Télécom, the 4-year project aims to improve the intrinsic properties of a composite material based on Elium via four concrete demonstrators.

-

Toray announces growth, investment in carbon fiber composite materials

As part of its 2023-2025 management strategy, Toray projects 42% growth for pressure vessels, 30% growth in carbon fiber composite materials revenue and a doubling of capital investment.

-

Composites end markets: Batteries and fuel cells (2024)

As the number of battery and fuel cell electric vehicles (EVs) grows, so do the opportunities for composites in battery enclosures and components for fuel cells.