3D weaving capabilities achieve complex shapes, reduce weight and cost

JEC World 2024: Bally Ribbon Mills is displaying film-infused 3D woven joints, woven thermal protection systems (TPS) and woven composite 3D structures.

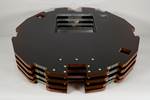

Bally Ribbon Mills (BRM, Bally, Pa., U.S.), a designer, developer and manufacturer of highly specialized engineered woven fabrics, highlight its 3D weaving capabilities, including film infusion capabilities for 3D woven joints, woven thermal protection systems (TPS), and advanced woven composite 3D structures, including 3D near-net shapes.

In BRM’s film infusion process, a frozen sheet or film of resin is infused onto the custom 3D woven joint. Film-infused 3D woven joints ship as pre-made assemblies, ensuring consistent quality control and saving customers the cost of infusing the resin themselves. BRM says it has perfected the science and art of 3D continuous weaving to fabricate such structures as “Pi – π,” double “T,” “H” and other complex shapes. Offering an optimal blend of strength, durability and structural integrity, these complex woven structures are used primarily in aerospace applications, often in airframe structural components and subassemblies including stiffeners and joints.

Those who visit the booth can see lightweight materials like 3D woven fabrics on display and learn about BRM’s multifunctional TPS for atmospheric re-entry. BRM has implemented weaving technologies to develop complex webbing for aerospace products. The woven TPS billet showcased at the booth is part of a line of products that was selected as the critical component of the heat shield on the Orion Crew Capsule, which helps protect against the extreme temperatures of atmospheric re-entry.

In partnership with NASA (Washington, D.C., U.S.), BRM has also developed the 3D orthogonally woven 3DMAT quartz material for the Orion multi-purpose crew vehicle (MPCV) compression pads. The 3DMAT quartz material was recently named the 2023 NASA Government Invention of the Year.

Also on display are lightweight, cost-effective, woven 2D and 3D composite structures. Using a multidimensional continuous weaving method, BRM produces textiles that can be fabricated into near-net shape structures. These advanced weaving capabilities offer customers new solutions that reduce weight and cost. The technology weaves complex shapes automatically, eliminating many costly, time-consuming and labor-intensive processes.

Visit Bally Ribbon Mills at Booth 6M38.

Related Content

-

Plant tour: Albany Engineered Composites, Rochester, N.H., U.S.

Efficient, high-quality, well-controlled composites manufacturing at volume is the mantra for this 3D weaving specialist.

-

Composite resins price change report

CW’s running summary of resin price change announcements from major material suppliers that serve the composites manufacturing industry.

-

3D-woven composites find success in aerospace, space

CAMX 2024: Bally Ribbon Mills experts are displaying the company’s various joints, thermal protection system (TPS) technologies and other 3D woven composites for mission-critical applications.