Johns Manville launches three nylon thermoplastic organosheet product series

The OS-6, NCF-6 and CR-6 series use in-situ polymerization technology for enhanced properties in lightweight structural applications.

Source | Johns Manville

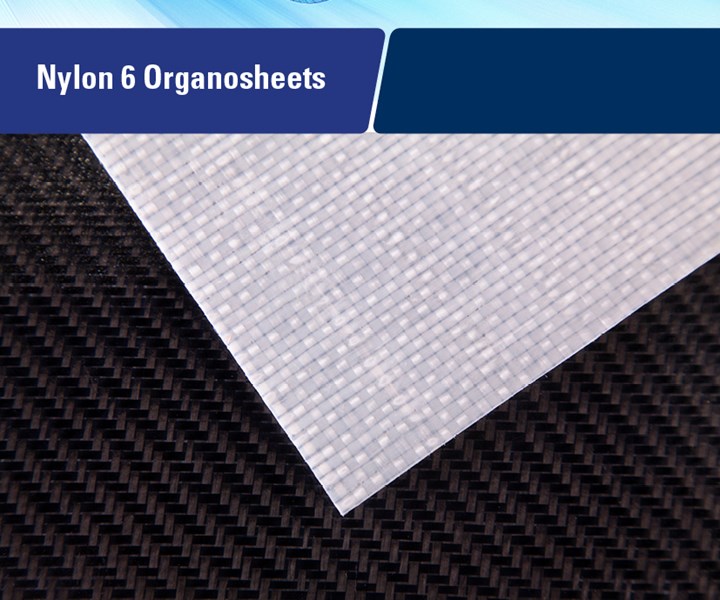

Johns Manville (JM, Denver, Colo., U.S.), manufacturer of continuous filament glass fiber and a Berkshire Hathaway company, has launched three nylon thermoplastic composite product series for lightweight applications: OS-6, NCF-6 and CR-6 series.

The OS-6 series is a nylon composites sheet reinforced with continuous woven fabric and impregnated with the company’s proprietary technology to enhance impact resistance, strength and stiffness in thermoplastic composites.

The CR-6 series is said to use chopped roving reinforcement to combine formability with impact resistance. Its quasi-isotropic properties reportedly enable a range of high-formability applications for thermoplastic sheets.

The NCF-6 series is reinforced with high-density continuous non-crimp fabric to offer high strength, stiffness and impact resistance in structural applications.

The company says its in-situ polymerization technology enables its nylon thermoplastic composite sheets to exhibit superior properties, short cycle times, recyclability and competitive costs.

Related Content

-

PEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

-

3D weaving capabilities achieve complex shapes, reduce weight and cost

JEC World 2024: Bally Ribbon Mills is displaying film-infused 3D woven joints, woven thermal protection systems (TPS) and woven composite 3D structures.

-

3D-woven composites find success in aerospace, space

CAMX 2024: Bally Ribbon Mills experts are displaying the company’s various joints, thermal protection system (TPS) technologies and other 3D woven composites for mission-critical applications.

.jpg;width=70;height=70;mode=crop)