Karl Mayer thermoplastic UD tape production line designed for mass production

The SIM.PLY production line is designed for large-scale production of thermoplastic UD tapes for lightweight structural compone

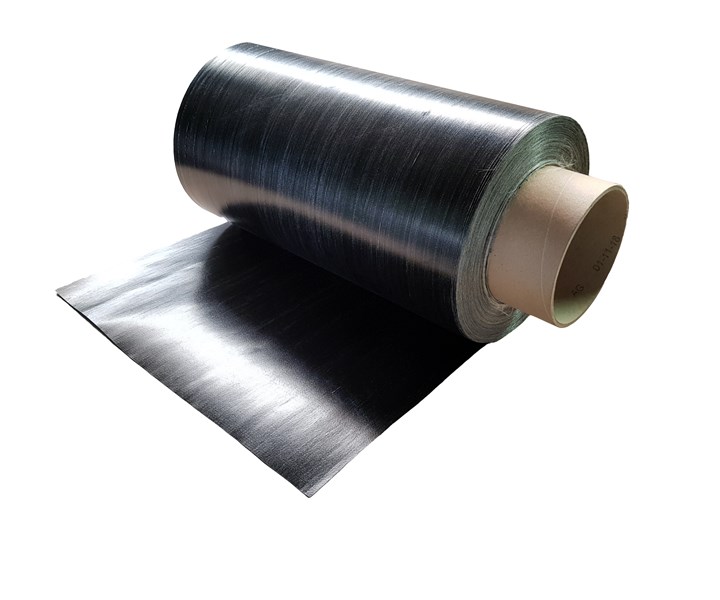

Continuous fiber-reinforced thermoplastic tape made out of glass fiber and polypropylene on Karl Mayer’s SIM.PLY production line. Source | Karl Mayer

Karl Mayer Technische Textilien (Obertshausen, Germany), a specialist in non-crimped fabrics for lightweight structural components, has introduced its latest production line, called SIM.PLY, which produces thermoplastic, unidirectional (UD), fiber-reinforced tapes.

The high-quality tapes, featuring precisely aligned, continuous fibers, are reportedly suitable for use in highly stressed, fiber-reinforced, lightweight structures. The thermoplastic matrix is said to make them easy to process for large-scale production. The SIM.PLY system operates at a high production rate and produces tapes in range of widths.

The company will display this technology at K 2019, Oct. 16-23 in Düsseldorf, Germany.

Related Content

-

The potential for thermoplastic composite nacelles

Collins Aerospace draws on global team, decades of experience to demonstrate large, curved AFP and welded structures for the next generation of aircraft.

-

TU Munich develops cuboidal conformable tanks using carbon fiber composites for increased hydrogen storage

Flat tank enabling standard platform for BEV and FCEV uses thermoplastic and thermoset composites, overwrapped skeleton design in pursuit of 25% more H2 storage.

-

Combining multifunctional thermoplastic composites, additive manufacturing for next-gen airframe structures

The DOMMINIO project combines AFP with 3D printed gyroid cores, embedded SHM sensors and smart materials for induction-driven disassembly of parts at end of life.

.jpg;width=70;height=70;mode=crop)