Lanxess offers fiber-reinforced PBT material solutions for radar sensor, electromobility applications

Fiberglass-reinforced PBT options meet demanding features for radar sensors in vehicle driver assistance systems (ADAS), high-voltage connectors, powertrains, EV battery casings.

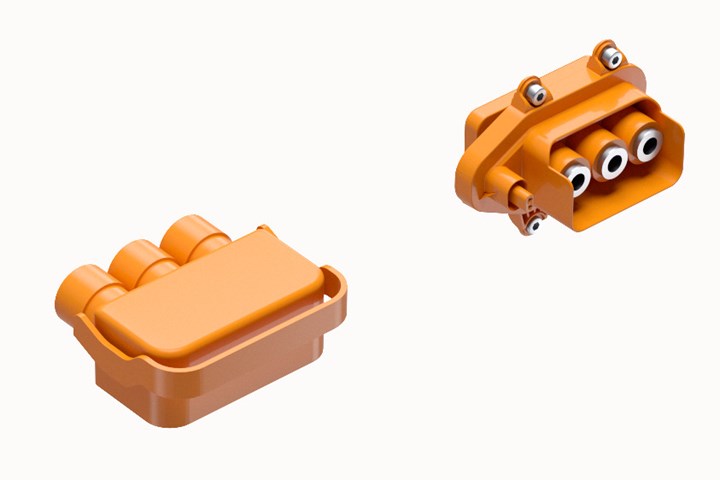

One potential application for the new PBT compound is high-voltage connectors. Photo Credit, all images: Lanxess

Lanxess (Cologne, Germany) is offering new polybutylene terephthalate (PBT) compound material solutions for radar sensors in vehicle driver assistance systems (ADAS) and high-voltage connectors (think powertrains, electric vehicle (EV) batteries or electromobility charging infrastructure). For ADAS sensors, the Pocan XHR series, including fiberglass-reinforced Pocan B3233HRLT, is suitable for less demanding hydrolysis stability requirements when joining the housing components of radar or camera sensors. Electromobility options include the halogen-free, flame-retardant and hydrolysis-stabilized Pocan BFN HR product range, reinforced with 25% by weight of glass fibers.

ADAS sensors monitor the entirety of a vehicle’s surroundings and are based on electromagnetic waves such as radar or laser beams (LiDAR), ultrasound or using imaging techniques. Lanxess says extensive testing on the Pocan XHR series has resulted in dielectric constant (Dk) and loss factor (Df) values — which need to remain low to minimize radiation losses — that are suitable for use with the ADAS radar frequencies of 77-81 GHz. The series is also said to meet the desired technical requirements with properties like good radar transparency and dimensional stability, good laser welding behavior and optimized mechanical properties for fastening the sensors in the vehicle safely and durably. High resistance to hydrolytic degradation, hot air and exhibition of high elongation at break values are additional features.

Specifically, Lanxess says the glass fiber-reinforced Pocan B3233HRLT material is both transparent to lasers and highly resistant in hot and humid environments, make it well suited to join housing radar or camera sensor components cost effectively using laser transmission welding, for example.

Glass fiber-reinforced Pocan BFN HR comprises high electrical properties that are hardly dependent on temperature and moisture in the typical operating conditions of high-voltage connectors; it can be used at temperatures of up to 150°C (302°F). It is also characterized by a high level of volume resistance and dielectric strength, and can be applied at voltages higher than 600 V, the company reports.

The material is also stable to hydrolysis. In specimen tests based on U.S. Society of Automotive Engineers (SAE, Warrendale, Pa., U.S.) SAE/USCAR-2 Rev. 6 long-term hydrolysis tests, the material achieved Class 3 — said to be a good rating. Similarly, a test specimen thickness of 0.75 mm also passed the UL 94 flammability test with a V-0 classification.

Lanxess says the compound range can also be colored in bright colors, something that has been increasingly used in EVs to identify live, plastic-encased components.

Beyond high-voltage connectors, applications for the new Pocan BFN HR product range in electromobility could potentially include miniature connectors, circuit breakers, terminal blocks and other similar applications.

Related Content

-

Seat frame demonstrates next-generation autocomposites design

Light weight, simplified/cost-effective manufacturing, passenger comfort and safety informed materials and process innovations and won awards for the 2022 Toyota Tundra‘s second-row seat frame.

-

Envalior offers novel Tepex composite for EV battery housings

Low-thickness, recyclable thermoplastic composite passes strict thermal runaway tests for EV battery housings.

-

Exel Composites supplies fiberglass profiles for Foton electric buses

Partnership with Chinese automotive manufacturer will see the implementation of pultruded profiles in various bus models, backed by weight savings, complex geometries and long life.