New high-performance pipes for oil and gas industry from KraussMaffei

KraussMaffei has announced two pipe extrusion technologies including a new thermoplastic composite pipes pilot line and a three-layer pipe with a functional inner layer made of polyamide.

KraussMaffei (Munich, Germany) on June 6 announced two pipe extrusion technologies.

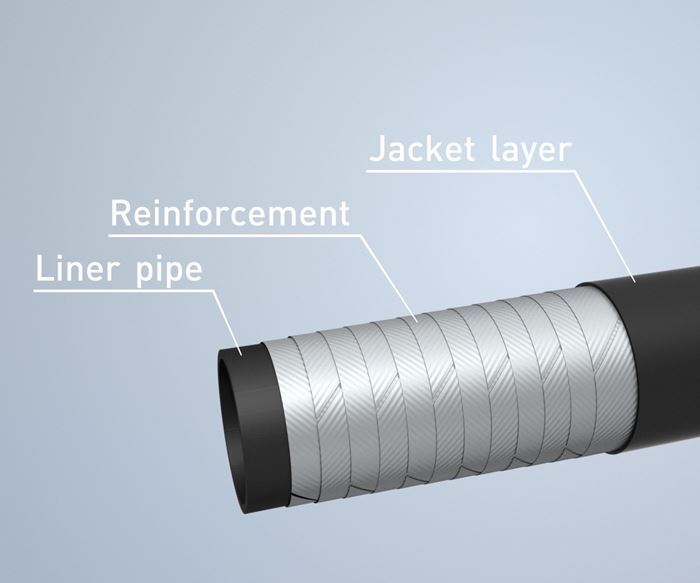

KraussMaffei Berstorff’s TCP (Thermoplastic Composite Pipes) pilot line supports pre-qualifying customer-specific sample pipes meeting the pressure standards of the oil and gas industry. The newly developed tube die also features a three-layer pipe with a functional inner layer made of polyamide (PA 12). This is well-suited suited for transporting corrosive and abrasive media.

"With our pilot line, we support our customers with their standards regarding the design of fiber-reinforced pipes from a process technology standpoint," says Matt Sieverding, president of Extrusion Technology at the KraussMaffei Group. The base pipe can be produced on the company’s in-house lines for manufacturing pipes, purchased on the market or provided by the customer. The tapes are then wrapped on the TCP pilot line. A reconfiguration of the line allows for subsequent sheathing with a protective layer.

At the second stage of the process, the surface of the polyethylene (PE) pipe on the winding system is heated with infrared. The tape is then attached at two successive winding stations. An infrared oven for each layer ensures the fusion of the inner pipe with the reinforcing layers, thus ensuring complete bonding. A corresponding guiding device ensures exact positioning and prevents potential tape overlapping.

"The fiber-reinforced pipes are excellently suited for the challenging safety requirements and high pressure loads in the oil and gas industry," Sieverding says.

In onshore use, the working pressure attains 150 bar at times. In offshore use, the pipe can be required to withstand a pressure stability of more than 500 bar.

Integrated into a complete production line, the KM-3L RKW 250 F³ tube die produces a three-layer PE pipe with a functional inner layer made from polyamide (PA 12), which offers high chemical and abrasion resistance. For complete bonding, an additional bonding layer is required. Due to their high impact strength and abrasion resistance, pipes manufactured in this way are well-suited to corrosive and abrasive media such as those frequently used in the oil, gas and chemical industries.

The live system with the KME 75-36 B/R, KME 45-36 B/R and KME 30-25 D/C single-screw extruders is designed for the dimensional range of 50 to 282 mm and an output of 800 kg/h for PE, 30 kg/h for the bonding agent and 180 kg/h for the functional layer.

Related Content

-

Thermoplastic composites: Cracking the horizontal body panel nut

Versatile sandwich panel technology solves decades-long exterior automotive challenge.

-

Plant tour: Sekisui Aerospace, Orange City, Iowa, Renton and Sumner, Wash., U.S.

Veteran composites sites use kaizen and innovation culture to expand thermoplastic serial production, 4.0 digitization and new technology for diversified new markets.

-

Manufacturing the MFFD thermoplastic composite fuselage

Demonstrator’s upper, lower shells and assembly prove materials and new processes for lighter, cheaper and more sustainable high-rate future aircraft.