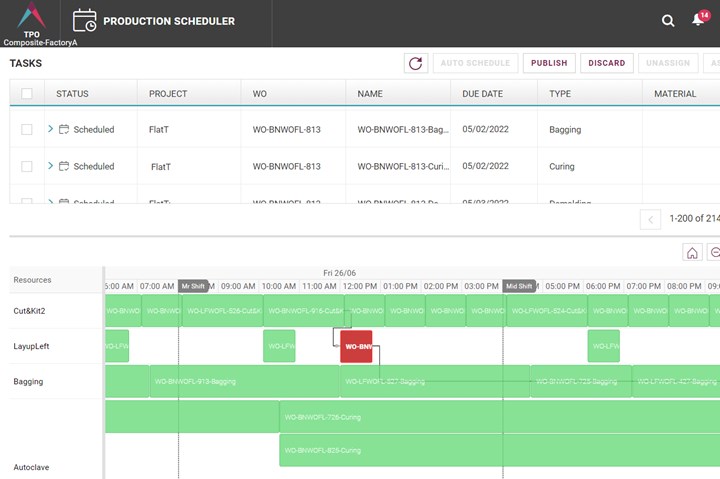

Plataine releases production scheduler version 4.0

The AI-based technology integrates production scheduling with shop floor management for a more efficient manufacturing process.

Source | Plataine

Plataine (Petach Tikva, Israel), provider of Industrial IoT (IIoT) and AI-based software for manufacturing optimization, has released version 4.0 of its cloud-based production scheduling application. Production Scheduler is part of Plataine’s Total Production Optimization (TPO) suite of applications such as Material & Asset Tracker, WIP Optimizer and Tool Manager, which integrates production scheduling with shop-floor management, streamlining production resources including materials, equipment and tools to make complex manufacturing processes more efficient.

Advantageous for planners and shop-floor employees, Plataine says its Production Scheduler provides a new, automated way to schedule and complete work orders, enhancing product operations according to set business KPIs (key performance indicators). Acting as a digital assistant, the application helps planners build a schedule and then monitors and adapts the actual production process, continuously improving it by comparing planned vs. actual development and reacting to unexpected events such as incoming rush orders, machine malfunctions and production delays. Applying AI-based technologies, the company says its scheduler also leverages bottleneck prediction and equipment efficiency.

Related Content

-

Carbon fiber, bionic design achieve peak performance in race-ready production vehicle

Porsche worked with Action Composites to design and manufacture an innovative carbon fiber safety cage option to lightweight one of its series race vehicles, built in a one-shot compression molding process.

-

The basics of composite drawing interpretation

Knowing the fundamentals for reading drawings — including master ply tables, ply definition diagrams and more — lays a foundation for proper composite design evaluation.

-

3D-printed CFRP tools for serial production of composite landing flaps

GKN Aerospace Munich and CEAD develop printed tooling with short and continuous fiber that reduces cost and increases sustainability for composites production.