Digital twin, digital thread and composites

How the integration of machines, sensors and software is beginning to impact composites manufacturing.

Photo Credit: cheskyw/123RF.com

I’m going to start this blog with some background and definitions. I will get to composites, but I think it’s important to understand the basic vocabulary first. So bear with me.

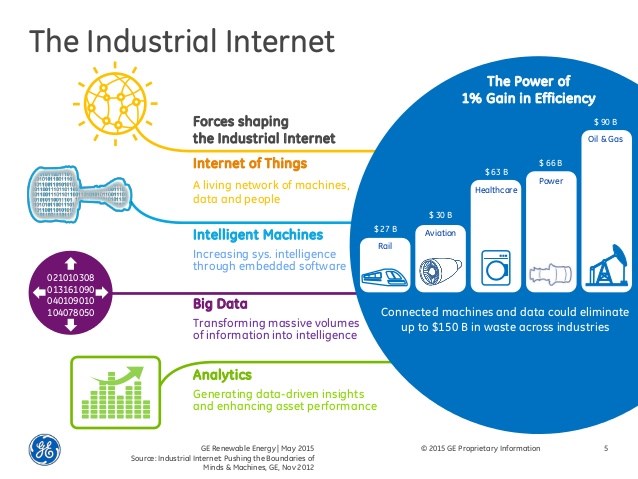

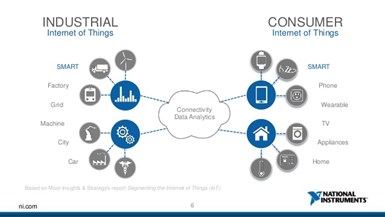

GE is a leader in developing the Industrial Internet, aiming to dramatically improve manufacturing and industrial efficiency. Source | slideshare presentations from GE (top) and National Instruments (bottom).

The Industrial Internet — referring to the Industrial Internet of Things (IoT) — is a term reportedly coined by General Electric (GE, previously Fairfield, CT and now Boston, MA, US) to describe the integration of complex physical machinery with networked sensors and software.

GE has actually been building an Industrial Internet platform since at least 2011, with some nascent movements as early as 2008. Though GE is not the only company developing technologies for the Industrial Internet — Siemens is another player — it is a leader and heavily invested.

- 2011 — CEO Jeff Immelt declared that GE needed to become a software and analytics company or risk seeing its hardware products become commodities as information-based competitors took over[1].

- 2012 — GE was ranked as the 14th largest software company.

- 2016 — Immelt announced the creation of GE Digital (San Ramon, CA, US), saying: “We are creating a $15 billion software and digital company inside of GE, built on agile and new business models.”

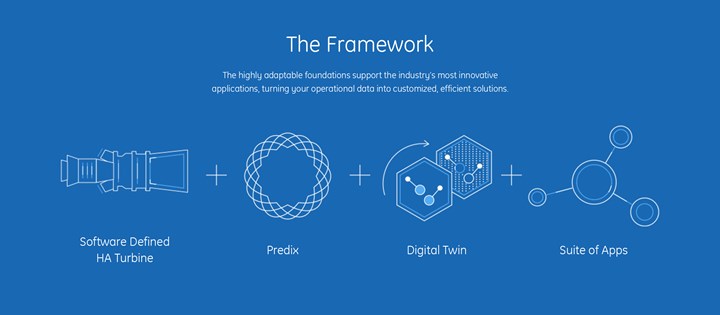

At the center of GE's transformation is Predix. Originally developed by GE to connect its own people, data and machines, Predix is now opened to outside companies. What is Predix? It is a technology platform that helps developers quickly build apps for the industrial internet. It has access to big data repositories (“data lakes”) and can be deployed in the cloud for more widespread access. Perhaps most importantly, it enables users to run analytics on big data, remotely monitor machines — e.g., jet engines, wind turbines, etc. — and even have machines talk to each other.

One of the big picture goals of Predix is being able to combine operational technology (OT) with information technology (IT). Bringing OT and IT together allows engineers and companies to see what’s going on in a machine, for example, whether something is wrong, and what can be done about it before it affects customers. Like doctors, the analytics can be used to predict when the machines might have problems in the future.

One example is in jet engines. These are currently outfitted with numerous sensors that provide data on various operational parameters, but that “just tells you there’s a problem,” says Bill Ruh, CEO of GE Digital. Analyzing these parameters for multitudes of engines, however, and combining with fleet analytics provides new insights and capabilities. As explained in Laura Winnig’s article, “GE’s Big Bet on Data and Analytics” in MIT Sloan Management Review:

“The company learned that hot and harsh environments — in places like the Middle East and China — clogged engines, causing them to heat up and lose efficiency, thus driving the need for more maintenance. GE learned that if it washed the engines more frequently, they stayed much healthier. “We’re increasing the lifetime of the engine, which now requires less maintenance, and we think we can save a customer an average of $7 million of fuel annually because the engine’s more efficient,” Ruh explains. “And all of that was done because we could use data across every GE engine, across the world and cluster fleet data.”

GE's vision of industrial internet solutions comprises Predix, apps and digital twins of physical machines like power turbines. Source | GE.

Note, this same goal is being pursued via structural health monitoring (SHM) systems. Changing operations from human-based decisions to analytics-based decisions is still new and often untrusted. Still, GE has set high goals, envisioning Predix as the iOS or Android of the machine world.

Digital Twin

A key concept within GE’s vision for the Industrial Internet is the digital twin, which is a virtual model of each physical production asset — i.e., each jet engine or wind turbine. As explained in article, “The digital twin”The Economist:

“The ultimate vision for the digital twin is to create, test and build our equipment in a virtual environment. Only when we get it to where it performs to our requirements do we physically manufacture it. We then want that physical build to tie back to its digital twin through sensors so that the digital twin contains all the information that we could have by inspecting the physical build,” says John Vickers, NASA’s leading manufacturing expert and manager of NASA’s National Center for Advanced Manufacturing.

Digital twins comprise elements like 3D CAD models, manufacturing simulations and real-time data feeds from sensors in the physical operating environment. The article goes on to assert that the real benefit of digital twins are actualized when all aspects, from design to real-time data feed, are brought together to optimize the asset over its lifetime. The goal is not to just cut prototyping or construction costs, but to predict failure more easily and accurately as real-time data is fed into the model, and thus reduce both maintenance costs and downtime.

GE Power & Water used digital twins in wind farms to increase performance and reduce cost. Source | GE.

An example of how digital twins will improve industrial performance is GE’s pilot “digital wind farm” concept. The digital wind farm design informs the configuration of each wind turbine prior to procurement and construction. Once the farm is built, each virtual turbine receives data from its physical twin. Software and the digital twins are then used to optimize power production of the wind farm by adjusting specific parameters in each physical turbine, like the torque of the generator or speed of the blades. GE hopes to achieve a 20% gain in efficiency.

According to the Economist article, “For every physical asset in the world, we have a virtual copy running in the cloud that gets richer with every second of operational data,” says Ganesh Bell, chief digital officer and general manager of Software & Analytics at GE Power & Water. “The Digital Twin is not a generic model. It’s a collection of actual physics-based models reflecting the exact operating conditions, such as lifing, performance and failure modes, in the real world.”

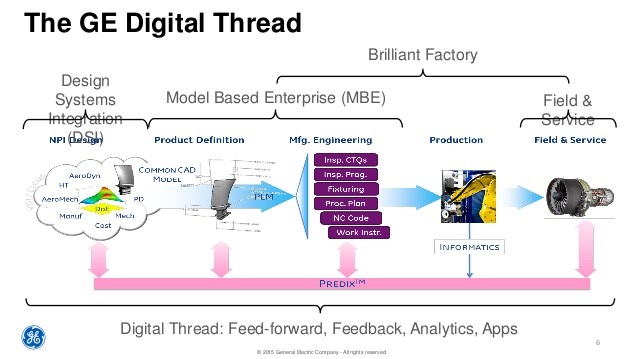

The GE Digital Thread. Source | GE, slide 6 from slideshare presentation “GE’s Digital Manufacturing Transformation”.

Digital Thread

One last definition before we discuss composites. Christine Furstoss, global technology director for GE Global Research, has described how GE sees the digital thread in the manufacturing.cioreview.com article “Digital Thread: Creating a Self-improving, Brilliant Factory”. She notes that Henry Ford perfected the assembly line and Toyota introduced “Lean Manufacturing”. GE has begun using sensors and big data analytics to improve both the speed and efficiency of manufacturing. It sees a self-improving, agile and connected supply chain communicating and operating through a digital thread in real time.

This thread begins when a new product designer creates a CAD model of the part or product to be made. Once optimized, the design is transmitted digitally to manufacturing engineering, where processes are modeled and simulated. Here, too, factory flow and layout, robots and manufacturing controls will be simulated and optimized. Once the design and processes are virtually validated, the data is transmitted to the brilliant factory, where intelligent machines will translate the data to manufacture the part or product. This factory is digitally connected real-time to its suppliers for optimal production control and logistics.

Here, GE really can’t claim pioneer status. Lockheed Martin has been talking about “digital tapestry” for years. In fact, Lockheed has put it into action as the leader of the Defense Advanced Research Projects Agency (DARPA, Arlington, VA, US) Transition Reliable Unitized STructure (TRUST) project. TRUST is pursuing certification of unitized bonded composite primary structures without redundant fasteners by using big data to achieve the manufacturing process control required for reliability. Similar to how GE’s digital twin gets better with every second of operational data, TRUST’s bayesian process control gets smarter with every part made.

Application to Composites

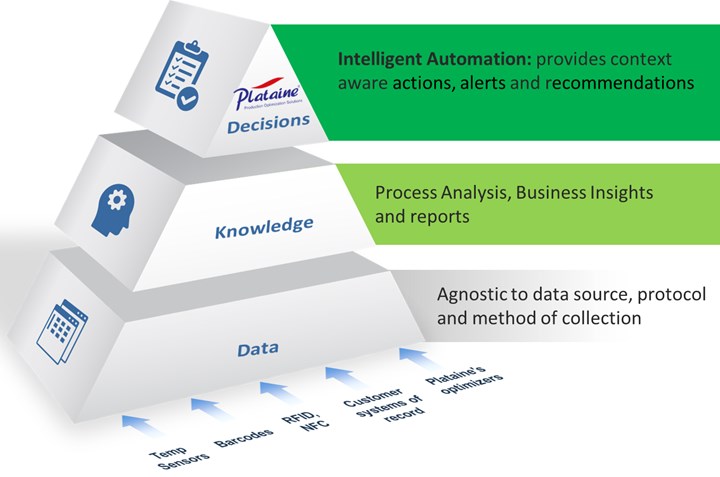

“We’ve actually implemented the Industrial Internet into composites manufacturing already,” says Avner Ben-Bassat, president of Plataine Technologies (Waltham, MA, US and Tel Aviv, Israel). (See “Applying the Industrial Internet to composites production” and “Optimizing composites aerostructures production”.) “We see an advancement and merging of traditional design tools and product lifecycle management (PLM) tools with data storage in the cloud and algorithms enabling intelligent manufacturing systems and anomaly detection.” What does this mean exactly?

“Say you have a part that fails a quality control check,” explains Ben-Bassat. “We can track that part’s digital thread back to the details of its tooling, layup and material lot numbers. If the issue stems from a mold that needs maintenance or a materials issue,we can immediately access the thread of every other part using those materials and pull them from the line. We can even pull them from customer sites before there is an operational problem.” But this is only possible with digital technology, Ben-Bassat notes. “With traditional methods, you’d be lost in paperwork for weeks.”

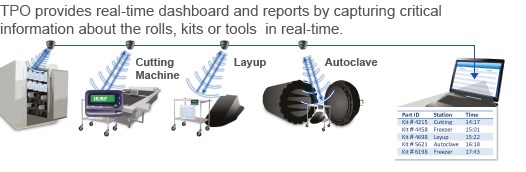

Plataine is already implementing Industrial Internet solutions into composites manufacturing. Sensor inputs (bottom of pyramid) include temperature, barcodes and RFID. Source | Plataine.

The software not only finds potential issues and correlations, but also makes decisions. “If parts are pulled from the production line,” notes Ben-Bassat, “then the system automatically triggers new production to meet schedule and any new input demand. In other cases, if a batch of prepreg is disqualified, the system will automatically reassign future jobs to alternative rolls."

Plataine has already begun working with GE, adapting its current Total Production Optimization (TPO) products to the Predix platform, but is also developing new applications. Ben-Bassat says the functions he is describing here are already offered today, and Plataine is filing patents for many new extensions of these capabilities.

One example is real-time, digital feedback loops between engineering, manufacturing and service. Ben-Bassat explains, “So with your digital tools in place, your part quality is consistent, but as you collect data you see that the part was designed to cost $1,000 but is actually exceeding $1,500 per unit. The digital systems we are putting in place actually provide the data feedback to engineering to address this cost overrun. It allows for better and more accurate identification of issues throughout the product life cycle and continuous improvement.” This enhanced business analysis is extended into in-service use as well. “Perhaps you achieved cost reduction and it now costs 50% less to make the part, but once it gets into service, repairs cost 75% more. We can identify that and feed the data back for improvement in design and manufacturing.”

“… there is now an opportunity to identify non-conforming parts before the end of the process chain and bring them back into acceptable limits, which saves both time and cost.”

Ben-Bassat says as aerospace OEMs continue to use Tier 1 and 2 facilities around the world to manufacturer components and sub-systems, it becomes critical to better manage quality control. “Right now, you have globally shared CAD systems which control part designs and drawings, but how do you transfer best practices for efficiency and quality in manufacturing?” He asserts that with sensors and the type of Industrial Internet applications Plataine is developing, “you know what each supplier is doing because you’re collecting all of the process parameter data real-time.” He adds that many companies have worked with Plataine in the past to pursue optimization of process control, “but now there is a dramatic increase in the data at our disposal, so we can achieve improvements much more quickly and drive increased value.”

Just as Lockheed Martin and DARPA identified in the TRUST program, there is now an opportunity to identify non-conforming parts before the end of the process chain and bring them back into acceptable limits, which saves both time and cost.

With Industrial Internet solutions and sensors collecting data throughout processing, it is now possible to identify non-conforming parts before the end of the process chain and provide feedback throughout the digital thread. Source | Plataine.

System cost – start small and scale over time

Plataine has made several announcements recently, partnering with companies like Siemens PLM (Waltham, MA, US), Argosy International (New York, NY, US) and Airbus’ Composite Technology Center (CTC, Stade, Germany). “By integrating our manufacturing automation and optimization solutions into their processes, we add more capabilities to the digital thread."

But isn’t all of this software and optimization expensive? “The prices of sensors have come down and continue to do so,” says Ben-Bassat. “You can set up RFID antennae for freezer tracking of prepreg for as little as $5,000 to 10,000.” He concedes that some of the big OEMs have invested over $100,000 in integrated digital systems, but there are also low-cost lab-scale systems for research organizations. The tracking and optimization software is offered on a subscription basis, minimizing the need for any further capital expenditure. “From Day One, we developed our software to be scalable up and down the digital thread,” says Ben-Bassat.

He adds that the future being offered with Predix is looking more to modular, collaborative solutions based on apps, like those commonly developed for iPhones and iPads. “What we are offering can start as local applications but then be distributed across operations, and also start as relatively simple feedback loops but over time integrate more algorithms to increase functions, the ability to respond to alarms and decision-making intelligence (Artificial Intelligence).”

[1] Quoted from Brad Power’s article “Building a Software Start-up Inside GE”, published on January 29, 2015 in the Harvard Business Review.

Related Content

Aurora reveals latest SPRINT X-Plane design concept

An Aurora and Boeing team advances its high-speed, vertical lift concept to the preliminary design phase, which features three lift fans, a more refined composite exterior and an uncrewed cockpit.

Read MoreCarbon fiber, bionic design achieve peak performance in race-ready production vehicle

Porsche worked with Action Composites to design and manufacture an innovative carbon fiber safety cage option to lightweight one of its series race vehicles, built in a one-shot compression molding process.

Read MoreProving thermoplastic composites match carbon fiber/epoxy performance in road bikes

CDCQ, LxSim, Addcomp and Argon 18 collaborate to optimize a carbon fiber/PA6 bike seat post, democratizing AFP and demonstrating materials and process for future designs and production.

Read MoreOptimizing robotic winding of composite tanks and pipes

Pioneer in mandrel-based reinforced rubber and composite products, TANIQ offers TaniqWindPro software and robotic winding expertise for composite pressure vessels and more.

Read MoreRead Next

Developing bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More