Precision-cut fibers for technical, wet-process applications

CAMX 2023: Engineered Fibers Technology (EFT) is exhibiting a range of its precision short-cut fibers and nanofibrillated pulps in addition to its work in contract R&D and product support.

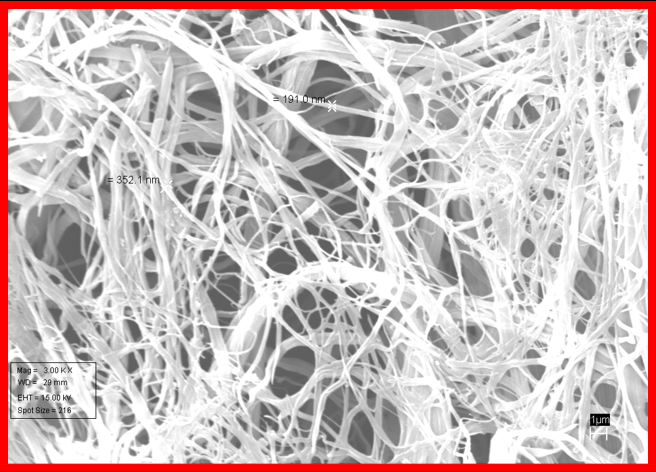

EFTec nanofibrillated fiber. Photo Credit: Engineered Fibers Technology

Engineered Fibers Technology (EFT, Rockford, Ill., U.S.) presents its wide range of textile/industrial-type and high-performance engineering-type precision short-cut fibers, in lengths from 0.25 mm to more than 75 mm. EFT maintains strategic alliances with several fiber producers worldwide to be able to provide the newest fiber products and highest levels of customer service.

Currently available fibers include crylic, modacrylic, lyocell, rayon, polyester, melamine, PVA, polypropylene, polyethylene, nylon, splitable bicomponent fibers, thermal binder bicomponent fibers and other specialty textile/ industrial-type fibers. Various engineering/technical fibers including pitch and PAN-based carbon fibers, nickel and copper carbon fibers, S-2 glass, quartz, PEEK, PPS, Ultem, Spectra, Vectran, PBI, fluorocarbons including PTFE and Halar, aramid, high modulus acrylic and PVA, and high tenacity polyester. Fiber orders from a few hundred grams to production (truckload quantities) can be delivered. EFT says it can also coat/size advanced fibers from aqueous-based polymers prior to cutting. Contract cutting services and special packaging options to meet specific customer requirements have been expanded.

EFT also has broad capabilities to provide highly fibrillated fibers/pulps including EFTec nanofibrillated acrylic fibers and EFTec nanofibrillated lyocell fibers with average fibril diameters of 0.2-0.3 µm for filtration and other wet-laid applications. Fibrillation capabilities range from laboratory-scale to large-scale commercial/container load production batches. Wet pulps are normally provided for wet-laid applications, but dry pulps can also be produced.

EFT is also continuing to expand contract R&D and provide product support to address specific customer requirements and applications. The company maintains a laboratory staff and has the ability to provide applications development and evaluation, as well as technical support to customers related to new short-cut fibers and pulps, with the major focus being on wet-laid papers, filtration media and slurry molded shapes.

Related Content

-

CAMX 2023 exhibit preview compilation, Part 2

Part 2 continues to showcase the materials, services, machinery, live demonstrations and other innovations presented by CAMX 2023 exhibitors.

-

Isobaric double belt press is well suited to continuous production

CAMX 2023: Flexible and robust double belt presses from Held Technologie are adaptable to various base composite material requirements to produce top-quality, long-lasting products.

-

Highly tunable, woven lattice reinforcements target automotive structures

CAMX 2023: Startup Weav3D will be demonstrating its two collaborative automotive demonstrator parts and present two conference papers.