Processing additives achieve improved fiber wetting

CAMX 2023: BYK USA is featuring its BYK-P 9920 solution, particularly well-suited for closed-mold composite applications, as well as other additives for the composites market.

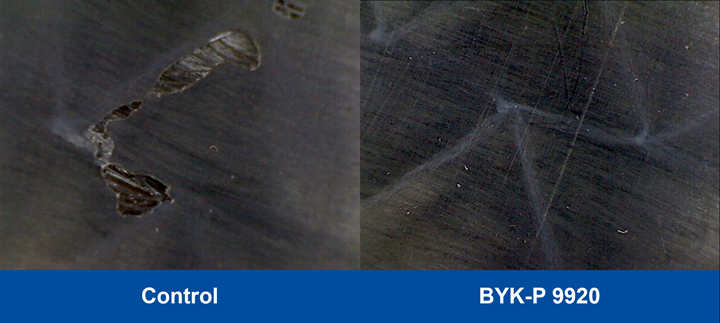

BYK USA (Wallingford, Conn., U.S.) presents BYK-P 9920, a processing additive specifically designed for advanced composite fiber-reinforced applications. It offers a number of benefits for composite systems, including significantly improving fiber wetting, which reduces and eliminates dry spots in the finished part, dramatically improving scrap rate and reducing rework. The increased fiber wetting also decreases mold fill times, allowing for faster part production and part turnover.

BYK-P 9920 is also an effective defoamer and air release additive, especially in epoxy systems. This air release behavior is beneficial in fiber-reinforced composites and floor coatings to eliminate porosity and air voids.

As BYK-P 9920 is high solids and emission-free, it is particularly well-suited for closed-mold advanced composite applications such as epoxy and vinyl ester systems with either glass or carbon fiber reinforcement. The epoxy-functional groups contained in the additive enable embedding into the resin matrix when the material is cured.

According to the company, BYK-P 9920 mixes very easily into liquid resins and is easy to incorporate into any production line at any processing stage. Its typical additive loading is low with regards to the overall resin system. Testing in systems using BYK-P 9920 show minimal or no adverse effect on mechanical properties or water absorption. Furthermore, it is storage stable within the resin system.

Related Content

-

CAMX 2023 Attendee Survey

CAMX – The Composites and Advanced Materials Expo is right around the corner, and we want to better understand your hopes and expectations heading into the show. CompositesWorld asks you to answer one of the five questions in the survey below. Responses will remain anonymous, and some may be published in the CAMX Show Daily, which is distributed at the show. The survey will take less than 5 minutes to complete.

-

CAMX 2023 exhibit preview compilation, Part 2

Part 2 continues to showcase the materials, services, machinery, live demonstrations and other innovations presented by CAMX 2023 exhibitors.

-

VIDEO: Robots enable nine-axis machining of composites

Machine Tool Camp displayed its hybrid machining center at CAMX, featuring nine-axis machining capability enabled by robotics.