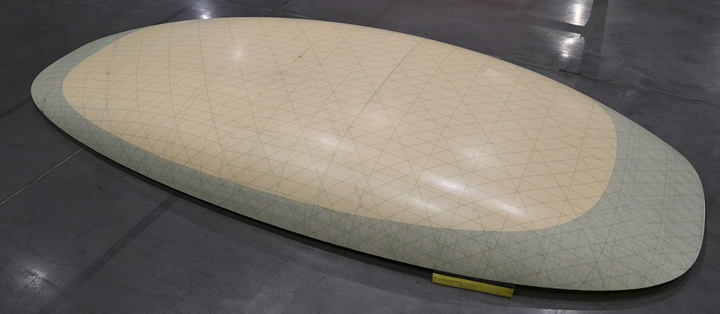

Radome concept highlights composite aerostructures expertise

JEC World 2024: Airbus Atlantic is displaying a carbon and quartz fiber radome, in addition to touching on its capabilities in design, development of aerospace structures, parts and equipment.

Since its debut last year, Airbus Atlantic (Toulouse, France), working in the design, production and integration of complex composite and hybrid aerostructures, is returning to JEC World showcasing a radome concept, a project dedicated to connectivity flight tests. The radome, made of glass and quartz prepreg, was designed by the Airbus Engineering teams in Toulouse, and manufactured at the Airbus Atlantic Technocentre in Nantes.

According to Airbus Atlantic, thanks to its dedicated and highly skilled teams in Méaulte, Salaunes and Nantes, it has developed and strengthened its expertise in composites, enabling the design and manufacture of a wide range of thermoset and thermoplastic aircraft structures, parts and aerospace equipment using cutting-edge composite technologies, including:

- Equipped aircraft sections and work packages (nose fuselage section and center wing box for the A350; aft fuselage panels for the A220; and equipped wings for the ATR).

- Large, complex parts for all type of aircraft (radomes, air inlets, wing flaps, keel beams, seat shells, etc.), as well as elementary parts (stringers, struts and more)

- Cockpit furnishing for the A320 and A400M

- Cabin furnishing, including window panels, bins, lavatories, ceiling, partitions and more for the ATR 42/72

- Premium passenger seat shells for all types of aircraft.

Airbus Atlantic encourages suppliers of innovative composite technologies (materials, tooling, processes, equipment, environmental products, etc.) to meet its R&T, procurement, business development and industry teams.

Visit Airbus Atlantic at Booth H106 in Hall 6.

Related Content

-

JEC World 2023 highlights: Innovative prepregs, bio-resins, automation, business development

CW’s Jeff Sloan checks in with JEC innovations from Solvay, A&P, Nikkiso, Voith, Hexcel, KraussMaffei, FILL, Web Industries, Sicomin, Bakelite Synthetics, Westlake Epoxy and Reliance Industries.

-

Innovation Award finalists revealed for JEC World 2024

Returning to the international composites trade show are the Innovation Awards, representing up to 33 finalists in 11 categories that highlight composites innovation excellence and fruitful collaborations.

-

What to expect at JEC World 2023: Exhibit previews

JEC World 2023 will be held April 25-27 in Paris, France. Check out CW’s exhibitor preview compilation to learn what to expect from some of this year’s exhibitors.