Innovation Award finalists revealed for JEC World 2024

Returning to the international composites trade show are the Innovation Awards, representing up to 33 finalists in 11 categories that highlight composites innovation excellence and fruitful collaborations.

Photo Credit: JEC

International composites trade show JEC World 2024, taking place March 5-7 in Paris, France, has announced the official lineup of finalists for this year’s Innovation Awards.

Each year, the JEC Composites Innovation Awards celebrate successful projects and cooperation between players of the composites industry. Over the past 26 years, the JEC Composites Innovation Awards program has involved more than 2,000 companies worldwide. Open to any company or R&D center with a strong collaborative innovation or concept to present, more than 225 companies and 573 partners have been rewarded over the years for the excellence of their composites innovations and fruitful collaboration. These composites champions are awarded based on multiple criteria such as partner involvement in the value chain, complexity or commercial potential of the project.

See last year’s finalists and award winners.

After pre-selection of the 33 finalists, one winner will be selected in each of the 11 categories: Aerospace – Parts; Aerospace – Process; Automotive and Road Transportation – Design Part; Automotive and Road Transportation – Process; Building and Civil Engineering; Circularity and Recycling; Digital, AI and Data; Equipment, Machinery and Heavy Industries; Maritime Transportation and Shipbuilding; Renewable Energies; and Sports, Leisure and Recreation. The awards ceremony will take place in Paris on Feb. 8, 2024.

The international jury representing the entire composites value chain includes:

- Hüseyin ATES, CTO and compounding BU leader, Kordsa

- Professor Alan Banks, innovation and industrial engagement supervisor, Ford Motor Co.

- Professor Christophe Binetruy of Centrale Nantes/Nantes Université

- Tamara Blanco, composite materials and processes engineer and expert, Airbus

- Dale Brosius, executive VP/chief commercialization officer, IACMI – The Composite Institute

- Michel Cognet, chairman of the board, JEC

- Dr. Karl-Heinz Füller, manager future exterior and materials, Mercedes-Benz

- Dr. Sung HA, professor of Hanyang University

- Guy Larnac, technical domain coordinator for materials, structures and industrialization JTFR, Ariane Group

- Professor Véronique Michaud, head of laboratory for processing of advanced composites (LPAC), EPFL

- Professor Kiyoshi Uzawa, professor/director, Innovative Composite Center, Kanazawa Institute of Technology.

**Editor’s note: Below are short excerpt summaries below for each finalist. For complete info, include key benefits of each technology innovation, please visit JEC’s linup page.

BioGear

BioGear is a helicopter landing gear blending carbon- and flax-fiber-reinforced composites, achieving a 60% weight reduction over traditional metal counterparts. BioGear not only enhances the emergency landing response but also prioritizes both efficiency and environmental impact.

Companies: Fuko srl (Italy) and partner Turtle srl (Italy)

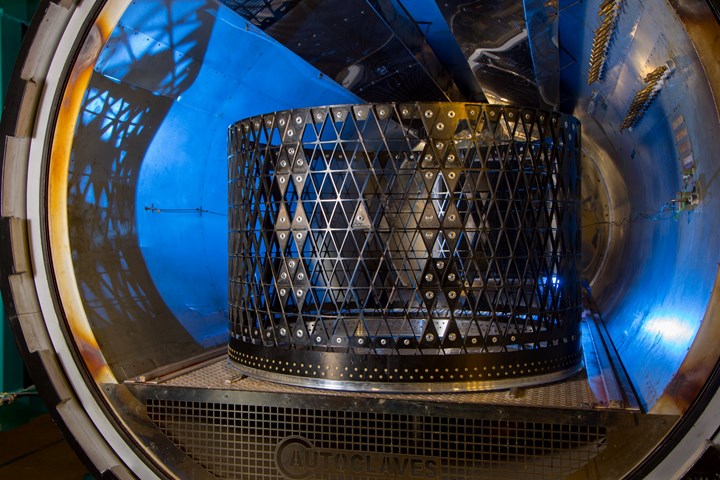

CFRP lattice satellite central tube

ATG Europe has developed a one-shot manufacturing process for uninterrupted prepreg fiber-placed lattice structures that aim to replace current satellite central tube designs. These cylindrical lattice structures offer optimal structural functionality at a reduced mass. This innovation included the design, development and manufacture of a fully representative carbon fiber-reinforced polymer (CFRP) lattice central tube based on requirements for ESA’s Plato satellite.

Companies: ATG Europe (Netherlands) and partner ÉireComposites Teo (Ireland)

Thermoplastic composite ebay door

Sogeclair Equipment, formerly known as Aviacomp, presents an aeronautic door featuring a complex stamping shape and advanced welding in thermoplastic composites. With integrated overmolded parts and an optimized design, the solution significantly reduces weight and assembly time using composite materials and induction welding. Materials used include thermoplastic PPS and carbon fibers fabric through injection molding, using a single material to facilitate recycling.

Companies: Sogeclair Equipment (France) and partner Airbus Atlantic (France)

ASPERA-welded thermoplastic composite demonstrator

In preparation for future aerospace challenges, Spirit AeroSystems fabricated details of an ASPERA article — representative of a large portion of a typical commercial aircraft cabin — using automated fiber placement (AFP), stamp forming and novel pressure intensification processes that were welded with patented co-fusion and induction to demonstrate fastener-free high-rate manufacturing.

Companies: Spirit AeroSystems (U.S.) with partners A&P Technology (U.S.), Concordia Fibers (U.S.), Electroimpact (U.S.), Mitsubishi Chemical Advanced Materials (U.S.), NIAR (U.S.) and Victrex (U.S.)

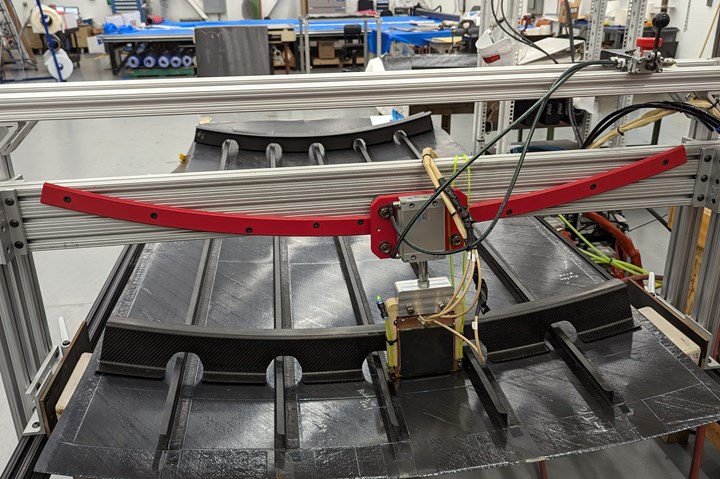

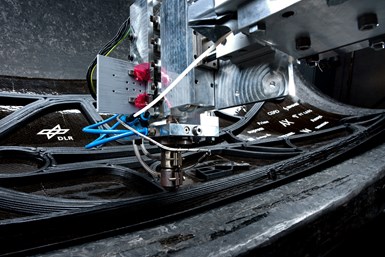

EmpowerAX — Additive functionalization

The EmpowerAX demo part is a multi-curved thermoset shell additively functionalized with short- and continuous fiber-reinforced elements realized by DLR and 12 EmpowerAX members. It demonstrates the industrially available process chain for additive functionalization.

Companies: German Aerospace Center (DLR, Germany), with partners 9T Labs AG (Switzerland), Airtech Europe (Luxembourg), Ansys Switzerland GmbH (Switzerland), CEAD B.V. (Netherlands), Ensinger GmbH (Germany), Fiberthree GmbH (Germany), FILL Gesellschaft m.b.H. (Austria), Hans Weber Maschinenfabrik GmbH (WEBER additive, Germany); Prime Aerostructures GmbH (Austria), Siemens AG (Germany), Suprem SA (Switzerland) and SWMS Systemtechnik Ingenieurgesellschaft GmbH (Germany)

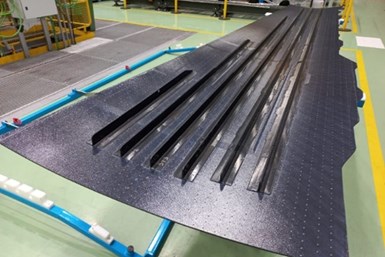

One-shot, in-situ consolidation upper wing cover

Airbus Defence and Space (engineering) and FIDAMC (manufacturing) have produced a thermoplastic in-situ-consolidated (ISC) upper cover for the AIRFRAME ITD Clean Sky 2 platform, for its integration into an outer external wing box specimen. The external wing skin cover, for a transport aircraft, is made of carbon fiber-reinforced PEEK, enabling low energy consumption processing and end-of-life recycling.

Companies: Airbus DS – Defence & Space (Spain) and partner FIDAMC (Spain)

Monolithic CFRP-aluminum monocoque: A novel approach for carbon neutrality

Photo Credit: Toyota Motor Corp.

A full-scale, variable-axial, CFRP-aluminum semi-monocoque prototype was designed, fabricated and evaluated. It was developed to demonstrate the potential of improving weight reduction in large 3D structures with complex topology and carbon neutrality through the effective use of CFRP. It shows a 15% weight reduction with minimal fiber waste (4%) and assembly cost.

Companies: Toyota Motor Corp. (Japan) and partners Toyota Central R&D Labs. Inc (Japan), Toyota Customizing & Development Co. Ltd. (Japan) and TISM Co. Ltd. (Japan)

Ultra-light CF thermoplastic composite door

Together, partners have engineered what is claimed to be the world’s first ultra- lightweight carbon fiber-reinforced thermoplastic (CFRTP) composite vehicle door that is 45% lighter than steel, meets static and dynamic crash performance metrics and is 100% reprocessable, signifying a major advance in sustainable automotive design.

Companies: Clemson University (U.S.) with partners Center for Composite Materials – University of Delaware (U.S.), Envalior (Germany) and Honda Development & Manufacturing of America LLC (U.S.)

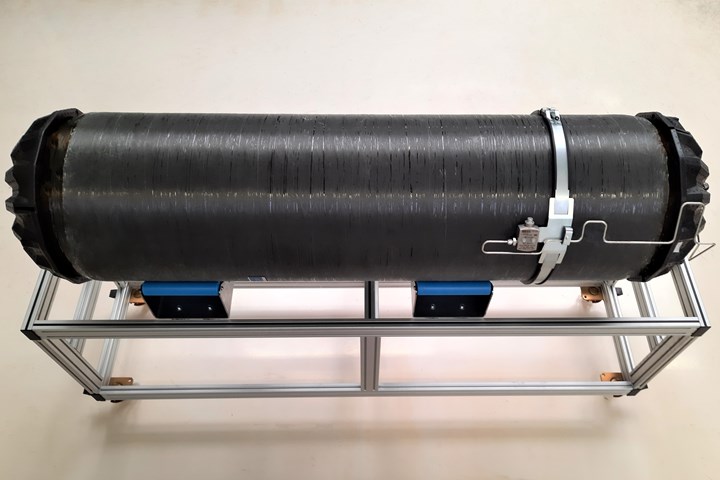

First certified large 350-liter Type 4 H2 700-bar tank

“Carbon4Tank” is reported to be the first UNECE R 134-approved 700-bar, 350-liter Type 4 hydrogen tank. The vessel is produced through an optimized towpreg winding process. The resin is specially formulated to allow the precise placement of fibers. It is geared toward heavy transport and commercial vehicles, and ensures maximum performance and minimum TCO.

Companies: Voith Composites SE & Co. KG (Germany) with partners Huntsman Advanced Materials GmbH (Switzerland) and Toray Carbon Fibers Europe S. A. (France)

Cost-effective automotive body structures

Weav3D’s composite lattice reinforcement enables lighter and less expensive thermoplastic solutions than conventional organosheet, unlocking new opportunities for cost-effective replacement of sheet metal structures with thermoplastics, as demonstrated through a beltline stiffener door component. The component was manufactured by laminating Weav3D’s lattices to Braskem’s extruded polypropylene sheet, grade TI4003F, using a continuous double belt press, then thermocompression molding the sheet in a matched-metal tool at the Clemson Composite Center, followed by final part trim via five-axis waterjet.

Companies: Weav3D (U.S.) with partners, Altair Engineering (U.S.), Braskem America (U.S.) and Clemson University (U.S.)

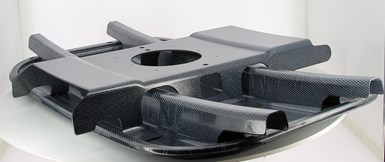

Automated preforming process for complex CFRP part

Development of a fully automated process for supplying complex preforms designed to achieve crash performance requirements while reducing the amount of carbon fiber used. Integrated sensors and vision systems provide high accuracy.

Companies: Teijin Automotive Technologies (France) with partners Dr. Ing. h.c. F. Porsche AG (Porsche, Germany), Airborne (Netherlands) and Pinette PEI (France)

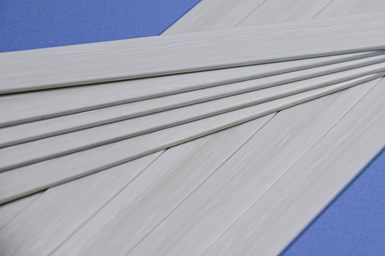

Reactive PA6 pultrusion: Boost for TP composites

Reactive thermoplastic pultrusion enables the production of cost-effective and highly resilient automotive components. The profiles are integrated in the final part by injection or compression molding. The PA6-based composites enable simple recycling without dismantling.

Companies: Röchling Automotive SE (Germany) with partners Fraunhofer Institute for Chemical Technology ICT (Germany) and Röchling Industrial SE & Co. KG – Haren (Germany)

Novel, sustainable façade enables BREEAM rating

A sustainable composite building façade for The Pulse of Amsterdam, features 14,000 square meters of Duplicor panels, incorporating approximately 1,100 composite elements. After several iterations, the targets for light weight, mechanical performance, fire resistance, sustainability, minimal maintenance and cost-effectiveness were successfully achieved.

Companies: Armacell Benelux S.C.S. (Belgium) with partners Holland Composites (Netherlands) and Solico Engineering (Netherlands)

Renco MCFR (mineral composite fiber reinforced)

Renco MCFR is a state-of-the-art structural building system comprised of interlocking composite building units of various types and sizes of blocks, columns, beams, joists, headers, decking, connectors, etc. These products are all adhesively joined (chemically bonded) to form monolithic structures. Renco products are manufactured with naturally occurring raw materials and newly composed materials from recycled products in an environmentally friendly manufacturing process.

Companies: Renco USA (U.S.) with partners Arquitectonica (U.S.), Catalyst Communications (U.S.), Coastal Construction (U.S.), DeSimone Consulting Engineers (U.S.) and DeVit Consulting Inc. (U.S.)

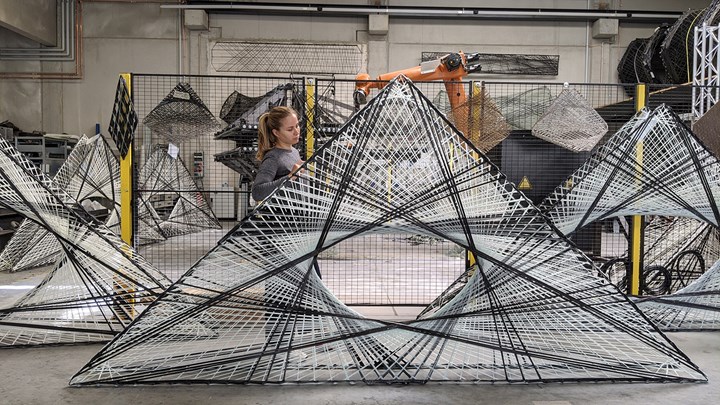

Robotically fabricated composite façade elements

Lightweight façade elements are manufactured using a highly resource-efficient, coreless robotic filament winding process using glass and carbon fiber towpregs. They are designed for high mechanical loads and optimized for specific degrees of shading with concurrent weather, UV and fire resistance.

Companies: FibR GmbH (Germany) with partners Covestro AG (Germany)

and Kümpers GmbH (Germany)

Building a closed-loop ecosystem for carbon fiber

Fairmat’s AI-driven and robotic technology creates 100% recycled CFRP chips. The chips are versatile for diverse product applications, offering high strength, stiffness and lightweight benefits while reducing environmental impact. Fairmat’s software-centric approach drives scalable, decarbonized manufacturing, closing the carbon fiber loop, and has been validated through more than 1,000 R&D tests.

Companies: Fairmat (France) and partner Hexcel Corp. (France)

Circular structures: Composites as a service

Greenboats GmbH’s approach reduces the environmental footprint and maximizes component use over their lifespan, multiplying eco-friendly benefits with efficiency to deliver durable, high-performance composites. Greenboats says its focus is on using natural fibers as reinforcements, coupled with plant-based resin systems, and incorporating either natural or recycled core materials.

Companies: Greenboats GmbH (Germany) with partners Depestele SAS (France), Hochschule Bremen (Germany) and Next Horizon Mobility GmbH (Germany)

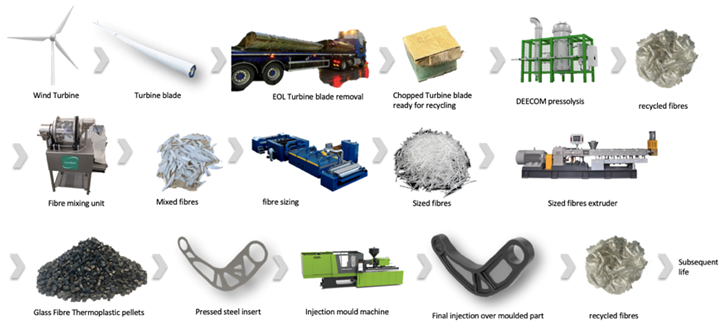

EMPHASIZING to enhance material property by sizing

EMPHASIZING aims to create a new advanced material, “glassene,” with prices close to glass fiber, performance to rival some carbon fiber and a very low lifecycle analysis (LCA). Fiberglass from a range of sources (wind, marine, fiber production) is reclaimed as 100% clean glass by the DEECOM pressolysis process. The fibers are chopped into 6-millimeter lengths before a range of sizing chemistries are considered, assessed and tested. Then they are compounded with polyamide thermoset resin and injection molded.

Companies: B&M Longworth (Edgworth) Ltd. (U.K.) with partners Autotech Engineering, Brunel University London (U.K.), EMS-Grivory (U.K.), Ford Motor Co. (U.K.), Gen2Plank Ltd. (U.K.) and TWI Ltd. (U.K.)

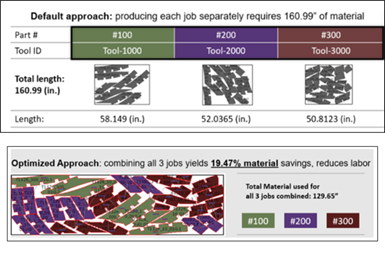

AI solutions improve sustainability and reduce waste

Plataine’s AI- and IIoT-based solutions drive factories to reduce composite materials waste and achieve higher sustainability and efficiency goals including reduce, reuse and recycle. Digital Assistants automatically track and optimize production planning to meet increased production rates.

Companies: Plataine (Israel) and partner MRAS, an ST Engineering company (U.S.)

Mobile energy analysis for sustainable production

Photo Credit: CTC GmbH

A holistic energy flow analysis was developed for data-driven improvement of current and future composite production. It has proven to be a multiplier for sustainable composite products, reducing energy needs and creating cost savings. Three analyses have been developed: Consumption Measurements to calculate saving potentials; Lifecycle Assessment Data Generation to accurately model an LCA; and Deep Energy Analysis which couples energy and process data for a holistic understanding to identify optimization potentials.

Companies: CTC GmbH (Germany) and partner Airbus Aerostructures (Germany)

Wind turbine blade executable digital twin

The wind turbine blade executable digital twin combines a reduced-order model with live sensor signal to assess structural performance in real time. Physical and virtual sensors combined is key to perform structural health monitoring (SHM).

Companies: ReliaBlade (Denmark) with partners Ceko Sensors (Denmark), Force Technology (Denmark), Siemens Industry Software (SISW, Belgium), Technical University of Denmark (Denmark) and Zebicon (Denmark)

Automatic composites molding system

Synthesites and partners have developed a fully sensorized intelligent mold, able to control the molding process in an optimal and automated way. Intelligent sensors are able to accurately follow the resin flow, viscosity and the glass transition temperature (Tg) and degree of cure.

This intelligent automatic molding system is presented for an industrial resin transfer molding (RTM) aerospace application, comprising: Durable sensors that work in direct contact with carbon fibers; a proprietary calibration technology for the accurate estimation of the resin’s viscosity, degree of cure and Tg; inline cure sensors for the online resin viscosity in the pipelines; and the Cure Simulator to simulate curing only by the temperature. This technology can reduce molding time by at least 15%, ensuring part quality.

Companies: Synthesites (Greece), with partners Safran Composites (France) and Safran Tech (France)

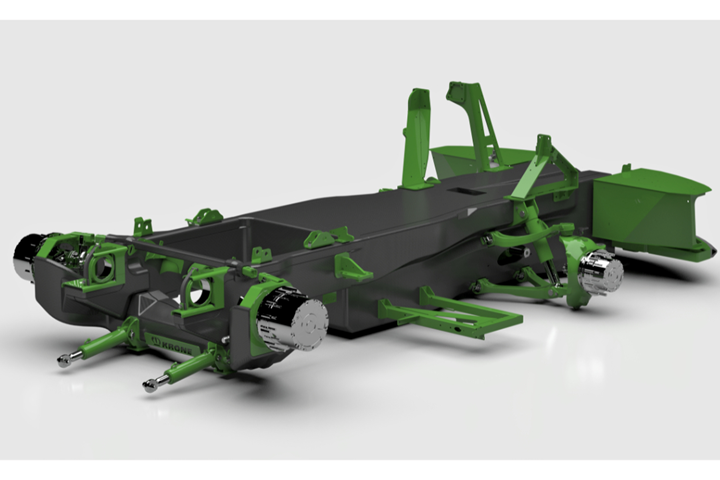

First carbon chassis for large agriculture machine

A novel function-integrated monocoque chassis for the Krone Big X forage harvester, made from a carbon fiber-reinforced thermoset composites design, manufactured using cost-effective vacuum infusion, enables more sustainable agricultural machinery. With a monocoque weight of around 300 kilograms, weight savings of more than 500 kilograms are possible compared to a steel frame.

Companies: AgriLight – Research Group (Germany) with partners Leibniz University Hannover, Institute of Production Engineering and Machine Tools (Germany), MD Composites Technology GmbH (Germany), Maschinenfabrik Bernard Krone GmbH & Co. KG (Germany) and Clausthal University of Technology, Institute of Polymer Materials and Plastics Engineering (Germany)

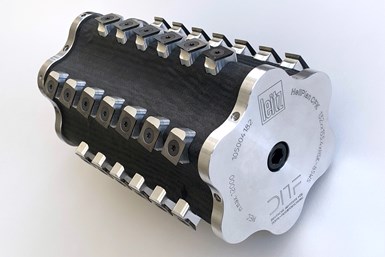

Maximum mass reduction of cutting tools

A new modular cutting tool for a woodworking machine has been developed, exploiting the mechanical advantages of CFRP. Design principles resulted in a tool design with triangular components that absorb centrifugal forces, and an outer shell that accommodates bending and torsional loads. More than 50% weight reduction and an increase in working speed of more than 50% has been achieved.

Companies: Deutsche Institute für Textil- und Faserforschung Denkendorf (DITF, Germany) with partner Leitz GmbH & Co. KG (Germany)

Hydrogen chase boat for America’s Cup Team

Advanced composite materials and structural engineering were used for the lightweighting of zero-emission marine structures. Gurit’s engineers worked alongside ETNZ to develop a innovative composite structure to ensure the greatest flexibility in design and installation of the hydrogen fuel cell and supporting systems for vessels that would act as on-water support during the America’s Cup.

Companies: Gurit (Switzerland) with partners McConaghy Boats (China)

and Team New Zealand Ltd. (trading as Emirates Team New Zealand/ETNZ)

OceanWings

OceanWings is a patented, automated, self-raising and lowering vertical wingsail system made of composites that enables newbuild or existing ships to reduce their fuel consumption and resulting carbon footprint by up to 50%. The technology enables the wing’s ability to withstand winds of up to 100 knots, while ensuring the proper functioning of its operations: automatic orientation in relation to the wind, adjustable camber, reefable and furlable.

Companies: AYRO (France) with partners Alizés (France), Jifmar Offshore Services (France), Zéphyr et Borée (France), Neptune Marine (Pays-Bas), VPLP Design (France) and ArianeGroup (France)

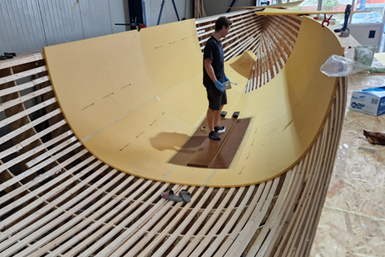

Tool-less composite builds by 3D core kit

Photo Credit: Paul Dijkstra Composites, Curve Works

A sailing yacht has been built using 3D core kits, eliminating traditional mold and tooling waste. A wooden jig is used to assemble and bond the thermoformed foam core, serving as the foundation for laminating the inner and outer carbon structure.

Companies: Paul Dijkstra Composites (Netherlands) and partner Curve Works (Netherlands)

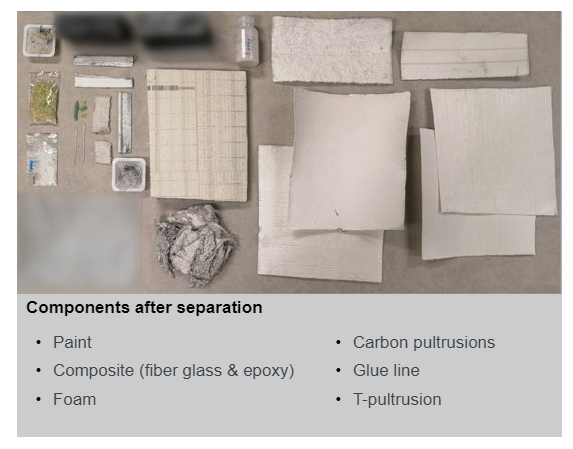

Blade circularity solution

CETEC’s blade circularity solution renders epoxy-based turbine blades circular without altering the material’s design or composition. It employs a chemical process, breaking down epoxy resin into virgin-grade materials, and precisely separating glass, carbon fibers, core material and metal components, establishing a circular economy for blade manufacturing.

Companies: Vestas Wind Systems A/S (Denmark) with partners Vestas (Denmark), Olin (Germany), Aarhus University (Denmark), Danish Technological Institute (Denmark) and Stena Recycling (Denmark and Sweden)

Photo Credit: Vestas Wind Systems

Enhancing circularity in renewable energy

Novel innovation eliminates landfilling of end-of-service wind turbine blades (EoSWTB) while substituting currently used galvanized ron (GI) profiles with composite profiles for installing pholtovoltaic panels in solar energy farms. This collaboration has met several challenges, including:

• Development of an industrial, cost-competitive and automatic process for shredding EoSWTB

• Ensuring production of moisture free, fine particle-size recyclate

• Developing resin-mix (resin-recyclate) formulation

• Developing a fiber impregnation and resin-mix injection system

• Developing a die for rapid profile manufacturing with minimum process waste generation

• Ensuring quick and easy installation of composite profile with fewer workers as compared to GI profile installation.

Companies: Acciona Construction S.A. (Spain) with partner Acciona Energia S.A. (Spain)

Wrapped composite joints for offshore renewables

Wrapped composite joints replace complex welding in lattice structures and provide optimized load transfer. Ideal for offshore wind foundations, they ensure faster and cost-effective fabrication and reduce steel consumption contributing to a lower carbon footprint.

The wrapped composite joint connects steel members by adding composite material exactly where it is required. All loads are transferred through the dedicated composite wrap and not through the limited surface of a weld, which reduces stress concentration, leading to lighter, cost-effective and longer-living offshore renewable structures (e.g., jackets, floating foundations).

Companies: Tree Composites (Netherlands) with partners Delft University of Technology (TU Delft, Netherlands) and Versteden B.V. (Netherlands)

Capital SL full-carbon wheelset

The Capital SL wheelset is said to represent a breakthrough in lightweight, aerodynamic design. It fully exploits carbon fiber through a patented manufacturing method and a simulation-based engineering approach, featuring a monocoque wheel system for integrated rim-spoke construction, enhancing structural integrity. Carbon fiber spokes, part of the monocoque structure, eliminate traditional interfaces, improving load transfer and reducing stress. Additionally, aerodynamic efficiency was a focus.

Companies: Radiate Engineering & Design AG (Switzerland) and partner

Scott Sports SA (Switzerland)

Green snowboard with A.L.D.-tech.

A snowboard with patented anisotropic coupling effect (A.L.D.-tech.) was made out of hemp and recycled carbon fibers (rCF) with bio-based epoxy resin. Thanks to the material properties of the hemp tape and the directional rCF nonwovens, both materials can be processed automatically using DFP. This saves 75% of cutting waste of the hemp fibers, saving cost and reducing the CO2 footprint.

Companies: silbaerg GmbH (Germany) with partners Sächsisches Textilforschungsinstitut e.V. (STFI, Germany), bto-epoxy GmbH (Austria), Circular MTC e.V. (Germany) and SachsenLeinen GmbH (Germany)

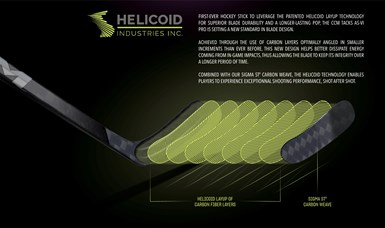

Helicoid/tacks ice hockey stick blade

The Helicoid architecture is providing unprecedented performance and longevity for ice hockey sticks’ blade under repeated high impacts. The structure controls the crack growth inside of composite and maintains high performance over a longer period of time.

The Helicoid technology consists of layers of aligned fibers which are stacked up with a progressive change in fiber orientation in the same direction, which leads to a helicoidal distribution of fiber orientations. Helicoid’s is smoothing the change in fiber orientation with interply angles <30°, reduces interlaminar stresses and improves toughness and durability while using the same materials and weight. The laminate keeps the same directional properties to meet the specific in-plane stiffness and strength requirements without affecting the playability of the product.

Companies: Helicoid Industries (U.S.) and partner CCM (Canada)

Related Content

JEC World 2024 preview

The world’s largest composites industry trade event returns to Paris, France, March 5-7, 2024, featuring exhibits, awards, conference programming and more.

Read MoreJEC World 2023 highlights: Recyclable resins, renewable energy solutions, award-winning automotive

CW technical editor Hannah Mason recaps some of the technology on display at JEC World, including natural, bio-based or recyclable materials solutions, innovative automotive and renewable energy components and more.

Read MoreJEC Composites Innovation Award 2023 winners

The JEC Group has announced the winner for each of the ten Innovation Award categories. Learn more about the winners, their projects and future expectations in person or via livestreaming at JEC World 2023.

Read MoreJEC World 2024 highlights: Thermoplastic composites, CMC and novel processes

CW senior technical editor Ginger Gardiner discusses some of the developments and demonstrators shown at the industry’s largest composites exhibition and conference.

Read MoreRead Next

Winners announced for SPE Automotive Innovation Awards

Eight category winners, the Hall of Fame award and the Vehicle Engineering Team Award and Lifetime Achievement Award winners were revealed at the Nov. 8 event.

Read MoreJEC Forum DACH reveals Startup Booster, AVK Innovation award winners

Awards highlight dynamic composite innovations in industry.

Read MoreJEC World 2024 spotlights composites sustainability, innovation

This past year’s JEC Innovation Planets and awards are returning, with new opportunities like Country on Stage, a Building & Infrastructure Planet and more villages dedicated to specific aspects of the industry.

Read More