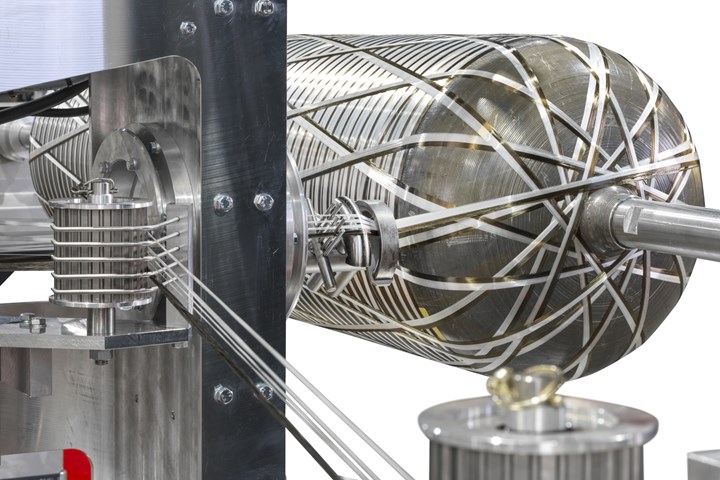

Roth Composite Machinery introduces the FWA 1 Duplex filament winding machine

Dynamic, multi-spindle machine enables the winding process to occur on both sides of the spindle, reportedly halving production time.

Photo Credit: Roth Composites Machinery

Roth Composite Machinery (Steffenberg, Germany) has launched the FWA 1 Duplex, a filament winding machine for the large-scale production of pressure vessels, particularly for commercial vehicles and trucks. Compared to the company’s conventional, multi-spindle machines, FWA 1 Duplex enables the winding process to occur on both sides of a spindle, reportedly making the production process 10-15% faster.

The machine features a strong frame construction with an additional spindle drive on the opposite side for dynamic filament winding, while also being capable of maintaining control over double the typical fiber volume. It is available with three, four or five spindles as well as an additional carriage system, if wanted. The machine is suitable for production processes for wet/dry towpreg winding procedures using all common fiber reinforcements, but especially carbon and glass fiber. According to Roth Composite Machinery, the Duplex production line offers 15% space savings on the production floor, and is 10% cheaper compared to other machinery with the same output capacity.

Related Content

-

A new era for ceramic matrix composites

CMC is expanding, with new fiber production in Europe, faster processes and higher temperature materials enabling applications for industry, hypersonics and New Space.

-

Pultrusion: The basics

A primer describing what pultrusion is, its advantages and disadvantages, and typical applications.

-

Combining multifunctional thermoplastic composites, additive manufacturing for next-gen airframe structures

The DOMMINIO project combines AFP with 3D printed gyroid cores, embedded SHM sensors and smart materials for induction-driven disassembly of parts at end of life.