Sicomin launches bio resin for HP-RTM processing

SR GreenPoxy 28 is a bio-based epoxy resin designed for fast cure, high performance, and more sustainable automotive manufacturing.

Share

Read Next

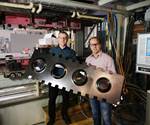

Sicomin’s GreenPoxy 28 is aimed specifically at the HP-RTM molding processes used for both high-performance automotive structural parts and aesthetic interior carbon fiber components.

Sicomin (Marseille, France), supplier of eco-resins, has launched a new bio-based epoxy resin aimed at high-pressure resin transfer molding (HP-RTM) for more sustainable automotive manufacturing.

SR GreenPoxy 28 is the sixth product in Sicomin’s GreenPoxy range. Certified by Veritas, SR GreenPoxy 28 is said to be a fast-cycle, low toxicity, third-generation bio-based formulation aimed specifically at the HP-RTM molding processes used for both high-performance structural parts and aesthetic carbon fiber components. Sicomin says the new formulation has been optimized for fast production cycle times and superior mechanical performance.

SR GreenPoxy 28 can be fully cured using a 2-minute cure cycle at 140˚C, producing an onset glass transition temperature (Tg) of 47˚C. Sicomin says it also has exhibited ideal mechanical properties under both dry and hot/wet test conditions.

“More and more manufacturers and suppliers are betting on bio-based alternatives derived from renewable raw materials,” says Philippe Marcovich, president of Sicomin. “The latest addition to our GreenPoxy range, SR GreenPoxy 28, is an exciting alternative to traditional resins providing exceptional performance and quality for high-volume programs.”

Related Content

-

Composites manufacturing for general aviation aircraft

General aviation, certified and experimental, has increasingly embraced composites over the decades, a path further driven by leveraged innovation in materials and processes and the evolving AAM market.

-

TU Munich develops cuboidal conformable tanks using carbon fiber composites for increased hydrogen storage

Flat tank enabling standard platform for BEV and FCEV uses thermoplastic and thermoset composites, overwrapped skeleton design in pursuit of 25% more H2 storage.

-

Composite molding compound replaces Invar for lightweight small satellite structures

Patz Materials and Technologies and Lawrence Livermore National Laboratory developed a new monolithic optics housing with 80% less weight, near-zero CTE and the high-volume manufacturing required for commercial space.

.jpg;width=70;height=70;mode=crop)