Sustainable date palm fibers developed from agricultural waste

Developed by an Egyptian research consortium, PalmFil fibers and nonwovens have been developed for use in automotive composite applications and more.

Source | PalmFil

PalmFil is a type of high-performance fibers and reinforcements extracted from the byproducts of date palms, developed by a consortium of five Egytpian researchers specializing in natural fibers. The fiber is designed to be both sustainable and economical in manufacturing — it is compatible with various methods of textile and composite processing and said to offer the light weight and other performance properties required for the automotive industry.

According to Dr. Mohamad Midani, a partner in the PalmFil consortium, there are more than 140 million date palms grown in the Middle East and North Africa, generating more than 4.8 million tons of byproducts from pruning. The PalmFil consortium set out to transform these byproducts into 1.3 million tons per year of natural textile fibers.

“In the 1980s, the shift from natural fibers to manmade fibers was mainly to bridge the gap between the increasing demand for textile fibers and the limited supply of natural fibers,” says Midani. “In order to reverse this shift, there is a need to explore more sources of natural fibers and increase the biodiversity of fiber crops. And that is exactly what we did.” According to Dr. Ahmed Hassanin, another consortium partner, the research was self-funded and represents a five-year collaborative effort.

Source | PalmFil

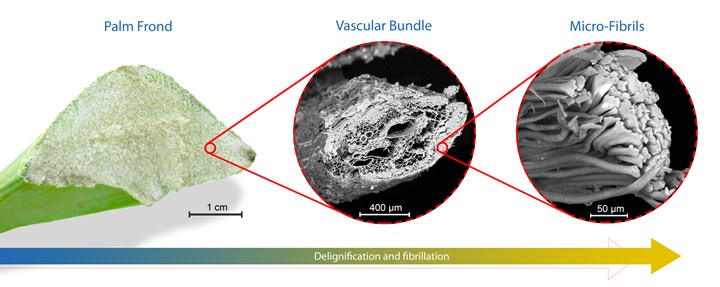

Previous attempts to extract fibers from date palm byproducts, the consortium says, used crushing and grinding methods, which resulted in a biomass rather than textile fibers. The PalmFil consortium claims to have extracted the first long textile fiber from such byproducts and converted it into fiber tow, chopped fiber, spun yarn/roving, nonwoven mat, woven fabric and unidirectional tape.

The fibers can be used in a range of industry applications, including use in composite automotive or sporting good applications, plaster reinforcements, packaging and other consumer products.

The date palm fiber, which comes from renewable bioresources, is said to be 100% biodegradable and compostable and has specific tensile strength five times higher than that of structural steel, and equal to those of flax, hemp and sisal. Its vibration damping and acoustical insulation is said to be higher than those of glass and carbon fiber, with thermal insulation higher than that of carbon fiber. Moreover, it can be easily blended with other long fibers such as flax, sisal and abaca, or it could be chopped and blended with hemp, kenaf and jute.

Source | PalmFil

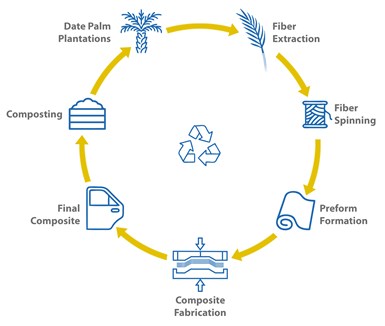

According to the consortium, PalmFil technology also contributes to the circular bioeconomy, following a closed loop cycle from cradle to cradle. Moreover, they say the extraction technology could be applied to byproducts of other palm species such as oil palm, sugar palm, doum palm as well as other agriculture byproducts such as broomcorn.

According to Dr. Tamer Hamouda, consortium partner, comprehensive research has been done to optimize the extraction process and characterize the new fiber, and the fiber has been processed on a full industrial-scale spinning line at the Egyptian Industrial Center of Flax. Hamouda adds that the consortium is currently establishing connections with automotive manufacturers in Europe and conducting research on date palm fiber composites for automotive applications.

“Date palm byproducts have been used for centuries in the Middle East and it is a heritage related material. ... Recent R&D conducted by PalmFil consortium demonstrates the potential of date palm fiber, its use in the modern context and in industrial settings. ... The key to its revival will be the national will and support to encourage the development of a reliable supply chain that can service the various production sectors that could use the fiber,” says Dilip Tambyrajah,secretary general of the International Natural Fiber Organization (Zoetermeer, Netherlands).

The PalmFil consortium is currently seeking partnerships to further develop, scale up and commercialize this technology. For more information on this product and the development team, visit palmfil.com.

Related Content

The potential for thermoplastic composite nacelles

Collins Aerospace draws on global team, decades of experience to demonstrate large, curved AFP and welded structures for the next generation of aircraft.

Read MorePlant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

Read MorePlant tour: Albany Engineered Composites, Rochester, N.H., U.S.

Efficient, high-quality, well-controlled composites manufacturing at volume is the mantra for this 3D weaving specialist.

Read MorePEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

Read MoreRead Next

Natural fiber enables e-bike for package delivery

New parcel delivery vehicle concept employs a natural fiber prepreg for low weight, vibration dampening, non-conductivity and flame retardancy.

Read MoreNatural fiber composites: What’s holding them back?

Natural fiber reinforcements have been available for some time, but factors such as compatibility with current processes and geographic availability continue to limit widespread use.

Read MoreNatural fiber composites: Market share, one part at a time

Suppliers and adventurous composites fabricators put the “feel good” aspect in the rearview mirror, winning customers by competing on price and performance.

Read More

.jpg;width=70;height=70;mode=crop)

.jpg;maxWidth=300;quality=90)