Swancor launches recyclable thermosetting epoxy resin

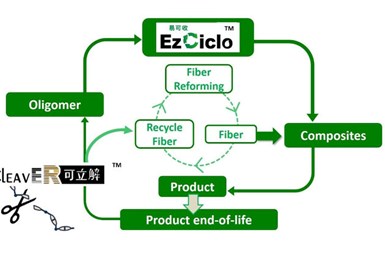

When used with composite reinforcements, EzCiclo can be recycled and degraded via the company’s CleaVER recycling technology with waste elimination and a final fiber with equivalent virgin fiber mechanical performance.

Swancor (Nantou, Taiwan) has launched two new products, EzCiclo and CleaVER, to offer a new solution to recycle and reuse wind turbine blades. EzCiclo is a recyclable and reusable thermosetting epoxy resin, which, when used with carbon or glass fiber reinforcement, can be recycled and degraded via the company’s CleaVER technology. CleaVER is said to turn waste into reclaimed glass/carbon fibers and oligomers (a molecule), which reuses both reinforcement and resin by closing the loop; the recycling process also does not generate waste solvents and pollution, Swancor says. It can be applied across a range of industries and manufacturing processes in addition to wind, such as sporting goods and automotive.

Photo Credit: Swancor

Compared with existing composites recycling methods — pyrolysis and solvolysis — Swancor says its recycling system does not need to change the current wind blades production process and equipment; it doesn’t crush the fiber-reinforced plastics (FRP) before the decomposition process; has no waste solvent and waste gas in the recycling process; recycled fibers show equivalent mechanical performance to new fibers; oligomer could be reused; produces a minuscule carbon footprint; and meets RoHS and REACH qualifications.

Related Content

-

Manufacturing the MFFD thermoplastic composite fuselage

Demonstrator’s upper, lower shells and assembly prove materials and new processes for lighter, cheaper and more sustainable high-rate future aircraft.

-

Plant tour: Albany Engineered Composites, Rochester, N.H., U.S.

Efficient, high-quality, well-controlled composites manufacturing at volume is the mantra for this 3D weaving specialist.

-

Natural fiber composites: Growing to fit sustainability needs

Led by global and industry-wide sustainability goals, commercial interest in flax and hemp fiber-reinforced composites grows into higher-performance, higher-volume applications.