Toray develops eco-friendly Toyoflon textile

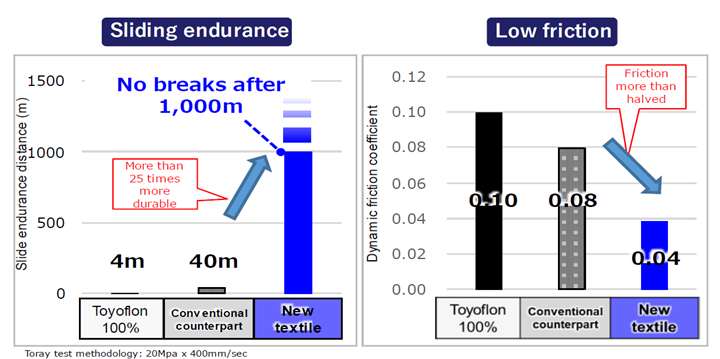

Toyoflon TM high-strength textile achieves slide durability 25 times greater than existing counterparts, with friction dropping by more than 50%.

Photo Credit, all images: Toray Industries

Toray Industries Inc. (Tokyo, Japan) has developed a high-strength textile that employs Toyoflon, a low-friction polytetrafluoroethylene (PTFE) fiber. The new textile, Toyoflon TM, is said to retain the friction resistance of fluoropolymers. Toray tests also found that the slide durability is 25 times greater than that of existing counterparts, with friction dropping by more than 50%.

According to the company, the high-strength textile, as a result of its aforementioned performance and high surface pressure, should reduce slide areas, while enabling miniaturization and weight reductions. Enhanced slide durability should also extend textile usage under tougher conditions, Toray notes, as well reduced environmental impact from oil-free sliding.

Toray says it will draw on these features to broaden applications, including for industrial machinery, plant facilities, automotive parts and bearings. The sliding material is applicable parts moving under high pressure

PTFE offers low friction and optimized heat and chemical resistance. Toray employed its matrix yarn technology by uniformly transferring Toyoflon TM wear particles to high-strength fibers under friction to form a low-friction interface. A high-strength fiber backbone prevents excessive wear. The textile also retains the features of PTFE resin, which the company claims is typically difficult to make into a fiber.

Related Content

-

Natural fiber composites: Growing to fit sustainability needs

Led by global and industry-wide sustainability goals, commercial interest in flax and hemp fiber-reinforced composites grows into higher-performance, higher-volume applications.

-

Plant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

-

The lessons behind OceanGate

Carbon fiber composites faced much criticism in the wake of the OceanGate submersible accident. CW’s publisher Jeff Sloan explains that it’s not that simple.