Search Results

Showing 501 – 510 of 1112 results

Composite materials are engineered combinations of two or more distinct materials, merging their individual properties to create a new material with enhanced characteristics. Typically composed of a reinforcing phase (like fibers or particles) embedded within a matrix (often a polymer, metal, or ceramic), composites leverage the strengths of each component to achieve superior strength, stiffness, lightness, or other desirable attributes. Their versatility extends across industries, from aerospace and automotive to construction and sports equipment, where their tailored design and exceptional properties offer solutions for high-performance applications.

Recycling in composites manufacturing is an evolving endeavor aimed at addressing sustainability challenges. Unlike traditional materials, composites often pose recycling complexities due to their multi-component nature. However, innovative techniques are emerging to tackle this issue. Methods like pyrolysis, mechanical recycling, and chemical processes are being developed to efficiently recover valuable components from composite waste, such as fibers or matrix materials.

Prepare for JEC World 2024 in March with this succinct and useful list of some of the exhibitors that will be present on the show floor.

Chopped fiber preforms in seconds, 1200°C burn resistance for hours, low-cost CFRP to replace metals

Guest columnists Lindsay Brooke, senior editor of the Society of Automotive Engineers’ (SAE) Automotive Engineering International magazine, says Carbon fiber’s decades-long promise in automotive composites might, indeed, be realized.

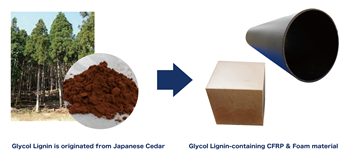

Eco-friendly resin system using glycol lignin offers an eco-friendly option for CFRP structures and components, and core materials.

A synergistic alliance combining Dieffenbacher’s production automation with Rein4ced’s hybrid Feather composite led to fully automated bike frame production line, which will be expanded to other composite products.

As the number of battery and fuel cell electric vehicles (EVs) grows, so do the opportunities for composites in battery enclosures and components for fuel cells.

Three-and-a-half-year, 11-partner EU project will include metals and composites spanning design, manufacturing, maintenance, repair, assembly and recycling.

The MAI Skelett project developed a thermoplastic composite roof structure that outperforms carbon fiber/epoxy design, including crash load level, energy absoprtion and BIW integrity.

Designed as part of the TPC-Cycle program, the flight-tested panel demonstrates a lighter, cost-effective, sustainable thermoplastic composite application.

Taking advantage of carbon fiber/PEEK mechanical and thermal performance, the Technical University of Munich replaces an aluminum rocket module with a 40+% lighter composite alternative.