Teijin Carbon America Inc.

(formerly DBA Toho Tenax America)

121 Cardiff Valley Rd.

Rockwood, TN 37854 US

800-252-3001 | 865-354-8408

aerospace@teijincarbon.us

teijincarbon.com

About Teijin Carbon America Inc.

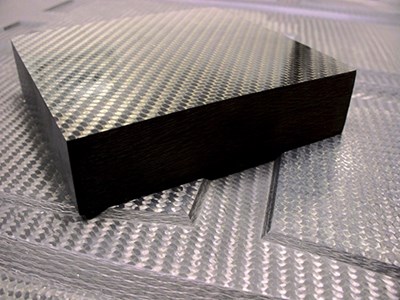

Sale and manufacture of trademarked Tenax PAN-based carbon fibers including standard-, intermediate- and high-modulus fibers; chopped and milled fibers and Pyromex oxidized PAN fibers (OPF). Fibers are manufactured in Japan, Germany and the US. Also Tenax Thermoplastic prepreg and laminates.

IS THIS YOUR COMPANY?

As Seen On CompositesWorld

Teijin Carbon America Inc. Supplies the Following Products

- Carbon

- Carbon, Multiaxial

- Carbon, PAN-based

- Epoxy, 350 F cure

- Epoxy, 350 F cure, 12-inch tape

- Epoxy, 350 F cure, 3-inch tape

- Epoxy, 350 F cure, 6-inch tape

- Epoxy, 350 F cure, Fabric

- Epoxy, 350 F cure, Other tape

- Fabric

- Fibers, metallized

- Tape, unidirectional

Trade Names Offered by Teijin Carbon America Inc.

Editorial, News, and Products

-

Sustainability-driven composite materials, recycling solutions

CAMX 2024: The Teijin Group, comprising Teijin Carbon America, Renegade Materials and Teijin Aramid, are featuring sustainable composite solutions, processes suited for a circular economy.

-

Plant tour: Teijin Carbon America Inc., Greenwood, S.C., U.S.

In 2018, Teijin broke ground on a facility that is reportedly the largest capacity carbon fiber line currently in existence. The line has been fully functional for nearly two years and has plenty of room for expansion.

-

PEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

-

Composites end markets: Aerospace (2023)

With COVID in the past and passengers flying again, commercial aircraft production is ramping up. The aerocomposites supply chain is busy developing new M&P for an approaching next-generation aircraft program.

-

Materials & Processes: Resin matrices for composites

The matrix binds the fiber reinforcement, gives the composite component its shape and determines its surface quality. A composite matrix may be a polymer, ceramic, metal or carbon. Here’s a guide to selection.

-

Materials & Processes: Fabrication methods

There are numerous methods for fabricating composite components. Selection of a method for a particular part, therefore, will depend on the materials, the part design and end-use or application. Here's a guide to selection.

-

The outlook for carbon fiber supply and demand

The picture painted at Carbon Fiber 2021 concerning the current supply and demand for carbon fiber indicates an in-flux, rapidly changing environment across a majority of end markets.

-

Carbon fiber suppliers gear up for next-gen growth

CompositesWorld’s annual Carbon Fiber conference was held in Knoxville, Tenn., U.S., in late 2019 and included a pre-conference seminar focused on carbon fiber supply and demand.

-

Leveraging composites for space tourism

Virgin Galactic’s WhiteKnightTwo will carry its SpaceShipTwo to launch position, then rocket passengers to suborbital space for a heavenly view of Earth.

-

Low-profile, high-performance manufacturer

Advanced Composite Products & Technology Inc. provides innovative and cost-efficient composite solutions to some of the most difficult and demanding real world applications.

-

IACMI announces collaborative smart composite pressure vessel project

The goal of the collaboration is to develop structurally predictable, low-cost smart composite pressure vessels (SCPVs) with integrated health-monitoring.

-

Teijin breaks ground for carbon fiber facility in South Carolina

TENAX manufacturing to start second half of 2020, targeting aerospace and automotive industries.

-

People on the Move: May 2018

CW’s monthly roundup of people on the move in the composites industry.

-

Exel acquires Diversified Structural Composites

With this acquisition Exel Composites expands into the American market – the second largest composites market globally.

-

Teijin integrates carbon fiber business under one name

The Japanese parent company Toho Tenax Co. Ltd. has been integrated into Teijin Limited.

-

I want to say two words to you: “Thermoplastic tapes”

Thermoplastic tapes are not new to composites, but they soon will join the primary aerostructures material palette and could be their future.

-

Consolidating thermoplastic composite aerostructures in place, Part 1

After more than 30 years of development, in-situ consolidation is nearing its promise to eliminate fasteners and the autoclave, and enable an integrated, multifunctional airframe.

-

Teijin to build new carbon fiber plant in South Carolina

Teijin Ltd. will build the facility in Greenville, SC, US, and expand its PAN precursor capacity in Japan. Further, the Toho Tenax unit is being folded into Teijin with the creation of Teijin Carbon Fibers.

-

Toyota fuel cell bus features carbon fiber composite roof

Toho Tenax carbon fiber and aluminum are combined in fabrication of roof for Toyota hydrogen-powered bus.

-

Composite chef’s knife a chef d’oeuvre

A while back I blogged about a luxurious version of a champagne flute, via carbon fiber and gold. The designer, Ragnar Friberg, is at it again, this time with a composite take on the chef’s knife.

-

Unweighting a crane to increase payload limit

Rethinking a crane stinger with carbon fiber for a more “uplifting experience.”

-

A tsunami of growth: An inside look at the CSP/Teijin merger

I had the opportunity to meet and interview the top executives of Continental Structural Plastics (CSP, Auburn Hills, MI, US) and Teijin Ltd. (Tokyo, Japan) last week. The occasion was an open house and celebration of the acquisition of CSP by Teijin.

-

Teijin acquires CSP: A safer growth choice?

Teijin’s presence in Auburn Hills is clearly another step into vertical integration of the supply chain.

-

Teijin + Continental Structural Plastics: Going forward

With Teijin set to take the reins of Continental Structural Plastics (CSP), both companies start thinking about how the future will look for this new autocomposites Tier 1.

-

Aerospace growth climbs with carbon fiber

The business case for carbon fiber in narrowbodies has become a lot stronger now that these operational benefits are in evidence.

-

Teijin goes public with long-awaited Sereebo molding process

Teijin (Tokyo, Japan) revealed in Paris for the first time many details about its Sereebo high-volume composites manufacturing process.

-

JEC World 2016, the full report

CompositesWorld's editors report on the technologies and products that caught our eye at JEC World 2016, in early March.

-

Supply and demand: Advanced fibers

Demand for advanced fiber, virgin and reclaimed, is on an upswing after a dip during the recent recession. Fiber suppliers are gearing up to meet an expected increase in demand as manufacturers in a number of composites end-markets scale up or start up part development and production programs

-

Teijin sheds more light on Sereebo manufacturing process

Combining a chopped carbon fiber mat with nylon 6 resin, the process will be used to fabricate primary automotive structures in a forthcoming production vehicle.

-

Carbon in the cloud(s)

Carbon is the norm, and even a necessity, at the Pikes Peak International Hill Climb race event, held June 28.

-

Yachtbuilding Composites: Rigged for Success

Carbon composite cabling in several forms races ahead of dry fibers and stainless steel in sailboat rigging.

-

Supply and demand: Advanced fibers (2015)

Demand for advanced fiber, virgin and reclaimed, is on an upswing after a dip during the recent recession. Fiber suppliers are gearing up to meet an expected increase in demand as manufacturers in a number of composites end-markets scale up or start up part development and production programs.

-

The matrix (2015)

The matrix binds the fiber reinforcement, gives the composite component its shape and determines its surface quality. A composite matrix may be a polymer, ceramic, metal or carbon. Here's a guide to selection.

-

Articulated composite booms extend reach of concrete-pumping arms

A 25% weight reduction vs. legacy steel yields economics that justify upfront cost of carbon fiber.

-

CAMX 2014 show report

Bigger, better and more inclusive than any previous U.S. composites trade event, the inaugural show turns North American eyes forward to the future.

-

The democratization of carbon fiber

Composites industry consultant and regular HPC columnist Dale Brosius says the battle for carbon fiber’s industrial market will be won by suppliers with the lowest costs and greatest capacities.

-

JEC Europe 2014 Review

The composites world met again in Paris, vibrant, stronger, and more forward-looking than ever before.

-

JEC 2013 at first blush

CT Editor-in-chief Jeff Sloan risks some immediate reactions to his week in Paris at the JEC Europe 2013 composites trade show.

-

Composite fuselage helps HondaJet upend biz-jet market

CFRP composites enable unitized structure with low-drag aerodynamics that transform aircraft performance and reduce cost.

-

Q&A Forum: Automotive Composites

How will fiber-reinforced polymers fare in a post-recession, cost- and fuel-economy-obsessed auto market?

-

Composites 2010 Product Showcase

The ACMA’s Las Vegas exhibition reflected an industry in recovery.

-

Very Light Jets Creating A Demand For Composites

"Baby" jets are causing an aviation buzz but will the market exist?

-

Carbon fiber reclamation: Going commercial

As the first commercial-scale carbon fiber recycling operations go online, research continues into both recycling alternatives and applications for recyclate.

-

Cost- and time-saving preform process used for propeller spinner

Carbon fiber/epoxy spinner uses pulp slurry preforming process combined with vacuum infusion molding.

-

JEC COMPOSITES Show highlights

The annual gathering in Paris reflects the industry’s confidence that the market’s global growth will continue.

-

Carbon Fiber 2007 looks forward with optimism

As high demand confronts a still limited supply, industry insiders and analysts meet to assess carbon fiber’s future and review emerging applications.

-

Market Trends: Carbon fiber demand, supply and the commodity threshold

CompositesWorld conferences director Scott Stephenson notes the increasing evidence at Carbon Fiber 2007 that the carbon fiber market is maturing.

-

Paris Air Show review

The biennial aircraft showcase confirms composites as an established,permanent presence in commercial aircraft construction.

-

Carbon Fiber in the Wind

Is there a market for carbon composites in wind turbine blade construction? Yes, but the real question is, how big will it be?

-

Composite Automotive Crush Structures

Tests that characterize, isolate and accurately measure energy absorption modes provide auto engineers the data they need to develop predictive CAE models.

-

Composite spoilers brake Airbus for landing

New RTM'd carbon composite center hinge fitting withstands 20-ton air load in commercial jet spoiler assembly.

-

Composites connect with the world of cabling

Composite cables prove they can handle high tension - on land, over water and under the sea.

-

At the top and still climbing

Trek Bicycles' OCLV manufacturing method shortens cycle times and optimizes compaction in molded carbon fiber-bike frame components.

-

An Elegant Solution For A Big Composite Part

The rear pressure bulkhead for the Airbus A380 employs resin film infusion.

-

Design Issues With Tendons

A composite tendon is essentially a rope made from small-diameter rods, which are pultruded with carbon fiber. Multiple rods are gathered together and twisted slightly to form a strand, using typical wire rope stranding methods. Depending on the performance requirements, 10 to 40 strands, about 2 to 3 inches/5

-

Interplay Of Materials And Use Conditions Key To Design

A wide variety of thermoplastic resins is used for the inner fluid/pressure barrier layer, which contains the conveyed material and eliminates any possibility of weeping through the fiber composite. The most common are families of polyolefins (e.g., polyethylenes), polyphenylene sulfides (PPS), nylons (polyami