German composite specialist INVENT collaborates in SUSTAINair for increased aircraft circularity

Three-and-a-half-year, 11-partner EU project will include metals and composites spanning design, manufacturing, maintenance, repair, assembly and recycling.

Photo Credit: Aerocircular

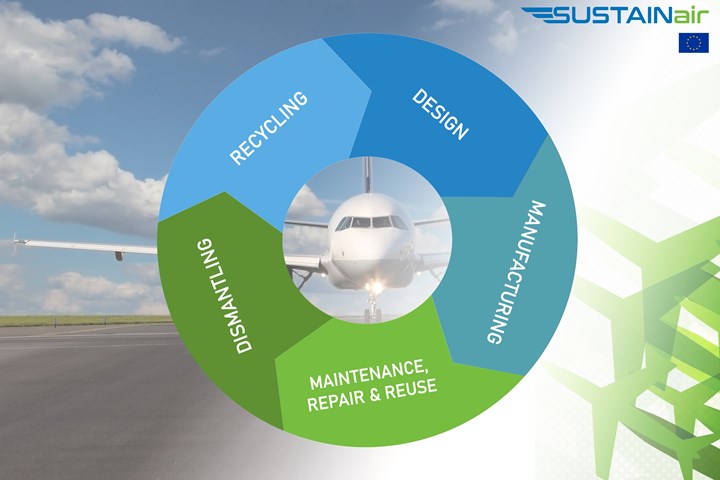

Horizon 2020 project SUSTAINair, a collaboration of 11 European research organizations and industrial partners, was recently launched in January 2021 to research and develop solutions to achieve a circular aviation economy. This includes increasing resource efficiency and aircraft performance while cutting down on waste and material costs throughout the aircraft life cycle. Consortium partners note that despite the aerospace sector’s plunge into uncertainty, boosting the post-pandemic aviation industry’s green transition remains a strategic objective of governments providing a path to recovery.

More specifically, the EU-funded research aims to make the entire aviation supply chain ecosystem greener in line with the Circular Economy Action Plan, setting new standards for aerospace manufacturing and enabling an increase in cross-sector synergies. The SUSTAINair project is expected to provide the aviation sector with a runway to a more cost-effective, low-carbon economy while tackling the increase in resource consumption, waste and emissions. It has been endorsed by the Future Sky research initiative of the Association of European Research Establishments in Aeronautics (EREA).

Coordinated by Jürgen Roither, research engineer at the Center for Low-Emission Transport at the Austrian Institute of Technology AIT-LKR (Seibersdorf), Austria's largest research and technology organization, the project is to span a period of 3.5 years with a budget of €5 million.

Upcycling solutions will be developed for carbon and glass fiber thermoset materials, as well as high-performance thermoplastic composites.

Roither stresses the complementary function of each project partner within a particular circular economy stage of the aircraft lifecycle. “SUSTAINair is addressing all phases of the aircraft component value chain from circular design to manufacturing, maintenance and repair, to assembly and recycling, and it will excel through the combined competence and expertise of its project partners,” he says.

Roither adds that material innovations in the highly regulated aviation sector need to be certified in order to fly. Because of this, SUSTAINair is seeking advice from the European Union Aviation Safety Agency (EASA, Cologne, Germany), which will be headed up by EASA Senior Research Coordinator, Willy Sigl.

“The contributions of EASA shall reduce the time to market of new innovative products and business models and enable a high level of safety, security and environmental protection. EASA therefore supports selected research projects, such as SUSTAINair, in an advisory role concerning certification, regulation and safety assessment aspects,” Sigl says.

Composite fiber specialist joins the project

Composite fiber specialist INVENT GmbH (Braunschweig, Germany) has also joined the SUSTAINair project. Since 1996, INVENT GmbH has been developing and producing high-precision structural components as an EN 9100- and Nadcap-certified company, from the initial idea to series production. This technological know-how and the manufacturing facilities will be used and further on developed within the project to achieve cost-efficient circular economy approaches for composite fibers.

Further, INVENT’s strong connection with the high-tech aeronautics sector enables the company to contribute to a range of high-impact activities within the project. Development of variable shape wings (morphing), integration technologies for sensor technology and novel reuse techniques of production waste, are just a few. INVENT plays a key role in the coordination and component-manufacturing for the demonstration of the technologies developed in SUSTAINair. The basic joining, interface design and metal manufacturing technologies will be transferred to more complex joint demonstrators, which will include sensor integration for structural health monitoring (SHM) and will be manufactured, tested and evaluated to validate the achievements of the project goals.

“The SUSTAINair project chooses a very holistic approach to the concept of circular economy tailoring it to the aeronautic context. This makes this an exciting project to be a part of and gives it potential for a real and lasting impact, not only for the environment, and the industry but also in regards to standardization policies,” summarizes Marc Joulian, SUSTAINair project manager at INVENT.

Landing the buy-to-fly ratio

The circular economy is an approach to make the most out of resources by keeping them in use for as long as possible, thus increasing their total value throughout their life cycle. The aerospace demand for high-quality material is typically accompanied by large amounts of waste during the manufacturing process. This applies to both metal alloys and composites.

The novel up- and recycling methods developed within SUSTAINair for both metal and composite aviation materials, will reportedly contribute to a major reduction of waste incurred during the manufacturing and end-of-life (EOL) processes. Upcycling solutions will be developed for carbon and glass fiber thermoset materials, as well as high-performance thermoplastic composites.

Photo Credit: RTDS Group

SUSTAINair co-ordinator Roither adds that the project aims to develop near net-shape components (manufactured as close to the size and the shape of the finished product) for the aviation industry to reduce the buy-to-fly ratio close to one, which is imperative if more material is used along the chain than is discarded. This is obtained by using recently invented nano-eutectic aluminium alloys at AIT-LKR in combination with advanced high pressure die-casting technologies. “Such processing is known in the automotive industry as ‘quick and efficient.’ SUSTAINair’s adapted technique and materials will make the manufacturing of aerospace components ‘quick, efficient and clean,’” Roither says.

Novel aerospace structures to reduce weight, CO2 emissions

Novel metal alloys and composite materials, such as carbon fiber-reinforced polymers (CFRP), are used to reduce mass and increase aerodynamic efficiency, improving fuel consumption during flight operations, and therefore reducing emissions. Minor changes to the materials or to the aircraft structure can have major results when it comes to fuel consumption.

With that in mind, SUSTAINair consortium partners are expected to develop not only novel materials for a flexible wing, but also techniques for the integration of sensors in the material used in such aircraft components. For example, the monitoring of real-time data enables the operators to adjust the flightpath of an airplane resulting in lower fuel consumption, while increasing the safety and the reliability of aero-structures, as well as reducing maintenance costs.

Such a combination of metal and composite materials does not come without technological challenges to joining and repair operations, however, as well as for circular approaches in the EOL process. “What is unique about SUSTAINair is that the design process will be formed to allow for innovative techniques along the value chain which will give the material a longer life with more value, accounting for EOL disassembly and upcycling,” says Chiara Bisagni, professor in aerospace structures and AIAA Fellow, at TU Delft, Netherlands.

Disassembly robot to enhance recyclability

Aircraft consist of many parts from various materials that need to be joined. Currently the joining is done by using rivets, which are difficult to remove. This makes separation, and the efficient recycling of aircraft components challenging and costly to the point of being not economically viable. Rivets also make aircraft heavier, negatively affecting fuel consumption. The particular expertise of project partners in welding and in other joining techniques could ultimately eliminate the need for rivets. According to project partners, this innovation cannot be adopted without changes to the current standards given by aviation authorities such as EASA.

Introducing Industry 4.0 technology in aircraft EOL processing, the SUSTAINair project is to also develop a robot head that automatically detects and removes rivets, enabling alloy separation and hence higher value recycled aircraft material. “To support the joining and removing activities, INVENT has developed a new technology to realize damage-free separation of adhesive bonded composite components. SUSTAINair gives us the opportunity to further on develop it,” adds Jesper de Wit, SUSTAINair project manager at INVENT.

On Flightpath 2050

The project partners are on the forefront of circular aviation pursuing objectives set by the EU Green Deal and Flightpath 2050. The technological innovations brought about by the transition to a circular economy can be seen as a pathway for tackling the economic effects of the COVID-19 pandemic in industries along the entire aviation component supply chain.

The partners of the project are: AIT-LKR Leichtmetallkompetenzzentrum Ranshofen GmbH (Austria), Netherlands Aerospace Centre – NLR (Netherlands), Deutsches Zentrum für Luft- und Raumfahrt e.V. – DLR (Germany), JOANNEUM RESEARCH (Austria), Johannes Kepler University Linz (Austria), Delft University of Technology (Netherlands), AEROCIRCULAR (Belgium), INOCON Technologie GmbH (Austria), INVENT GmbH (Germany), Dutch Thermoplastic Components B.V. (Netherlands), RTDS Association (Austria)

This SUSTAINair project has received funding from the European Union's Horizon 2020 research and innovation program under grant agreement 101006952.

Related Content

Welding is not bonding

Discussion of the issues in our understanding of thermoplastic composite welded structures and certification of the latest materials and welding technologies for future airframes.

Read MoreMFFD thermoplastic floor beams — OOA consolidation for next-gen TPC aerostructures

GKN Fokker and Mikrosam develop AFP for the Multifunctional Fuselage Demonstrator’s floor beams and OOA consolidation of 6-meter spars for TPC rudders, elevators and tails.

Read MoreJEC World 2024 highlights: Thermoplastic composites, CMC and novel processes

CW senior technical editor Ginger Gardiner discusses some of the developments and demonstrators shown at the industry’s largest composites exhibition and conference.

Read MoreManufacturing the MFFD thermoplastic composite fuselage

Demonstrator’s upper, lower shells and assembly prove materials and new processes for lighter, cheaper and more sustainable high-rate future aircraft.

Read MoreRead Next

INVENT GmbH demonstrates sensor network for structural monitoring on composite railcar structures

Patented DuraAct technology uses piezo-ceramics to detect damage in Deutsche Bahn train side skirts as part of faWaSiS research project.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read More