Mitsubishi Chemical Carbon Fiber & Composites Inc.

Mitsubishi Chemical Holdings Group

1822 Reynolds Ave.

Irvine, CA 92614 US

949-253-5680

mrcfac.com

About Mitsubishi Chemical Carbon Fiber & Composites Inc.

IS THIS YOUR COMPANY?

As Seen On CompositesWorld

Mitsubishi Chemical Carbon Fiber & Composites Inc. Supplies the Following Products

- Carbon, PAN-based

- Epoxy, <12K tow

- Epoxy, >12K tow

- Epoxy, 12-inch tape

- Epoxy, 250 F cure

- Epoxy, 250 F cure, <12K tow

- Epoxy, 250 F cure, >12K tow

- Epoxy, 250 F cure, 12-inch tape

- Epoxy, 250 F cure, 3-inch tape

- Epoxy, 250 F cure, 6-inch tape

- Epoxy, 250 F cure, Fabric

- Epoxy, 250 F cure, Mat

- Epoxy, 250 F cure, Other broadgoods

- Epoxy, 250 F cure, Other tape

- Epoxy, 250 F cure, Roving

- Epoxy, 3-inch tape

- Epoxy, 350 F cure

- Epoxy, 350 F cure, <12K tow

- Epoxy, 350 F cure, >12K tow

- Epoxy, 350 F cure, 12-inch tape

- Epoxy, 350 F cure, 3-inch tape

- Epoxy, 350 F cure, 6-inch tape

- Epoxy, 350 F cure, Fabric

- Epoxy, 350 F cure, Mat

- Epoxy, 350 F cure, Other broadgoods

- Epoxy, 350 F cure, Other tape

- Epoxy, 350 F cure, Roving

- Epoxy, 6-inch tape

- Epoxy, Fabric

- Epoxy, Film

- Epoxy, Hot melt

- Epoxy, Mat

- Epoxy, Other

- Epoxy, Other broadgoods

- Epoxy, Other tape

- Epoxy, Roving

- Epoxy, toughened

- Epoxy, toughened, <12K tow

- Epoxy, toughened, >12K tow

- Epoxy, toughened, 12-inch tape

- Epoxy, toughened, 3-inch tape

- Epoxy, toughened, 6-inch tape

- Epoxy, toughened, Fabric

- Epoxy, toughened, Mat

- Epoxy, toughened, Other broadgoods

- Epoxy, toughened, Other tape

- Epoxy, toughened, Roving

- Epoxy, Water-based

- Materials analysis

- Other thermosets

- Other, <12K tow

- Other, >12K tow

- Other, 12-inch tape

- Other, 3-inch tape

- Other, 6-inch tape

- Other, Fabric

- Other, Film

- Other, Foam

- Other, Mat

- Other, Other broadgoods

- Other, Other tape

- Other, Roving

- Tooling prepreg

Editorial, News, and Products

-

Hybrid battery cover: Materials, process decisions

A Q&A with Timo Huber, vice president of HRC’s Advanced Composite Technology Center, discusses material and process considerations for HRC Group’s SMC electric vehicle battery cover research project.

-

Combining materials for better bicycles

Bicycle manufacturer HIA Velo combines composite materials to make its products more durable.

-

Making better composite bikes in Arkansas

Bicycle manufacturer HIA Velo (Little Rock, AR, US), maker of carbon fiber bikes, is using a combination of composite materials to make their products more durable.

-

How is tow spread?

ITA characterizes tow spreading processes and parameters as it develops new technology to speed production (100 m/min) and reduce width variation (<1mm).

-

SMC: Old dog, more tricks

In the sheet molding compound renaissance, the advent of new resins and compounds are broadening the definition and application of this versatile family of composites.

-

Unweighting a crane to increase payload limit

Rethinking a crane stinger with carbon fiber for a more “uplifting experience.”

-

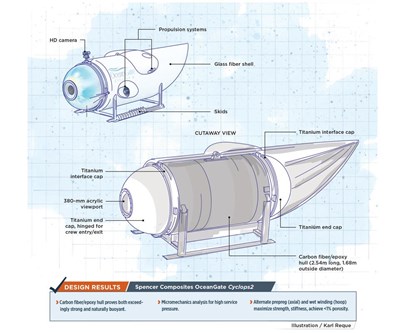

Composite submersibles: Under pressure in deep, deep waters

Manned deepsea exploration calls for a highly engineered composites solution that saves weight and preserves life — at 6,500-psi service pressure.

-

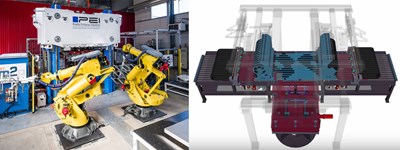

JEC 2017 – Aiming for Industrialization

The exhibit floor in Paris reflected composites’ move toward high-rate and high-volume production.

-

JEC World 2016, the full report

CompositesWorld's editors report on the technologies and products that caught our eye at JEC World 2016, in early March.

-

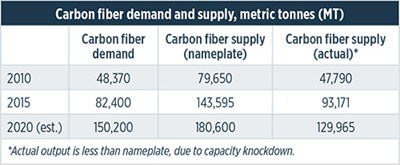

Supply and demand: Advanced fibers

Demand for advanced fiber, virgin and reclaimed, is on an upswing after a dip during the recent recession. Fiber suppliers are gearing up to meet an expected increase in demand as manufacturers in a number of composites end-markets scale up or start up part development and production programs

-

Lower cost, less waste: Inline prepreg production

New technologies move direct (fabricator-based) prepregging closer to reality.

-

SPE’S ACCE 2015 Preview

Automotive composites remain a hot topic in the Motor City.

-

Prepreg compression molding makes its commercial debut

Ultra-thin, preformed laminate designs enable CFRP decklid manufacture at lower-than-expected mass and at cycle times approaching mass-production speed.

-

Yachtbuilding Composites: Rigged for Success

Carbon composite cabling in several forms races ahead of dry fibers and stainless steel in sailboat rigging.

-

Supply and demand: Advanced fibers (2015)

Demand for advanced fiber, virgin and reclaimed, is on an upswing after a dip during the recent recession. Fiber suppliers are gearing up to meet an expected increase in demand as manufacturers in a number of composites end-markets scale up or start up part development and production programs.

-

Pressure vessels for alternative fuels, 2014-2023

Lower fuel costs and escalating emissions standards are driving a 10 percent annual growth in alternative fuel pressure vessel sales.

-

Ramping up to the carbon fiber supply challenge

HPC guest columnist Tom Lemire, president of T.F. Lemire Consulting Inc. (Irvine, Calif.), comments on the necessary response of carbon fiber suppliers to the likely increasing demand for carbon fiber in the coming years.

-

BMW Leipzig: The epicenter of i3 production

A glimpse into the inner workings of an automaker at the forefront of serial-production autocomposites.

-

Carbon stairs make boarding a sailing yacht a breeze

GMT Composites (Bristol, R.I.) makes lightweight but strong — typically carbon fiber — yacht-boarding systems that are easily moved and stowed.

-

SPE ACCE 2013 Review

The SPE’s annual Automotive Composites Conference & Exhibition gets a bigger venue, an expanded program and its best attendance ever.

-

Acoustical architecture: Making beautiful music

On the market for more than 40 years, composite musical instruments have advanced from a novelty to critical acclaim.

-

Composites as costume: Manga masterpieces

Sophisticated design meets composite materials and manufacturing in cosplay application.

-

Sailing the sea with composite wings

Autonomous sailing vessel patrols with patented WingSail technology.

-

Designing bicycling’s lightest pro racing frame

Cervélo’s Vroomen White Design group combines analysis and manufacturing acumen to create a 675g/1.5 lb composite frame.

-

In search of a better ride

Composites minimize weight on this mountain bike’s unconventional, single-sided front-wheel suspension system.

-

Shared composite material property databases

For more than a decade, NASA, FAA, industry and academia have been working toward the goal of creating a centralized composite material property database similar to that for metals. Their efforts, while productive, have not come with the war-like strength that the standardization of metals did. The composites industry is guided by Composite Materials Handbook 17 or CMH-17 (formerly known as MIL-HDBK-17).

-

Flying high on composite wings

FRP wings, fuselages and other primary and secondary structures on GA prop, turboprop and jet aircraft help lift this market to unprecedented heights.

-

Engineering Insights: Have Surfboard, Will Travel

This two-piece surfboard for the world traveler clamps together for seamless world-class performance.

-

Plane Enthusiasts Plan LSA-compliant Composite Aircraft

Aspiring owners build and - plan to market - their own tandem seat, twin-boom pusher.

-

Aluminum Frame Build Incorporates Carbon Fiber Tubing

Frame designers improve bike performance and comfort by incorporating prepregged carbon-fiber braid.

-

An update on composite tanks for cryogens

More automation, improved materials bring composite fuel tanks for space applications closer to reality.

-

At the top and still climbing

Trek Bicycles' OCLV manufacturing method shortens cycle times and optimizes compaction in molded carbon fiber-bike frame components.

-

Carbon fiber raises consumer performance index

Carbon bridges gap between large-volume sporting goods and aerospace to satisfy discriminating tastes in consumer and professional markets.

-

Carbon composites move beyond racing yachts into commercial and military marine applications.

Marine carbon composites move beyond racing yachts into commercial and military vessels.

-

Roll-wrapped golf club shafts feature sophisticated prepreg layup

Roll-wrapped golf shafts are produced through advanced laminate software program.

-

Schooner features carbon fiber masts, booms, spreaders

When Lion's Whelp, built by Portland Yacht Services (Portland, Maine, U.S.A.) embarked on its inaugural cruise, even seasoned marine observers saw a 65 ft white schooner, reminiscent of the early 20th century's Alden Schooners, complete with spars authentically detailed from wood with traditional brass fittings. But

-

Towpreg Proves Cost-competitive For Wound Pressure Vessels

Design group's new winding option streamlines new pressure vessel development.