Application

Athletic shoe developed with repurposed thermoplastic waste

Manufactured via a single-step molding process, Decathlon’s Traxium Compressor soccer cleats propel the sporting goods market toward more recyclable solutions.

WatchCFRP breakdown poles designed for lightweight, long-lasting use in marine applications

Shellback Canvas LLC wanted to develop a cost-effective alternative to prepreg poles for its canvas boat awnings. The resulting Blacksticks comprise compression-molded carbon fiber braid and epoxy in a unique process.

Read MorePultruded fiberglass rods enhance athletic training device

Jump Sticks, developed by Flexi-StiX LLC, combine pultruded fiberglass rods within a PVC tube to produce a semi-flexible but resistant training device for enhanced dynamic athletic training.

Read MoreUniversity of Iceland develops process for manufacturing one-piece racecar airfoils

Called the “Spark” method and based on a method for producing CFRP prosthetics, this single-mold, adhesive-free process is said to show potential for a variety of applications.

Read MoreCustomized resin flow mesh products save time, cost for wind turbine blade manufacturers

As longer composite wind blades are developed, customized mesh products help OEMs and kitting companies control resin flow and remove air voids during infusion.

Read MoreHigher performance, lower cost helicopter rotor blades developed with OOA, FAA-qualified composites

Erickson Inc. and partner Toray Advanced Composites replaced legacy aluminum S-64 main rotor blades with out-of-autoclave, multi-material composite alternatives.

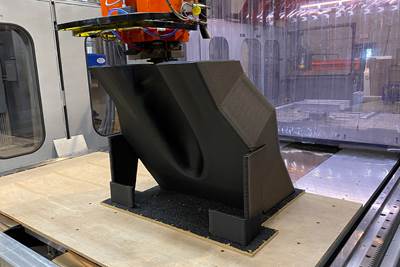

Read MoreCollaborative Boeing-led project validates large-scale composite AM tooling

The U.S. Navy-funded program demonstrated a large-scale, autoclave-curable 3D-printed carbon fiber composite tool using a Thermwood LSAM machine.

WatchCorrosion-resistant resins enable FRP petrochemical plant equipment

Spanish fabricator Ollearis used AOC resins and glass fiber filament winding to meet design and cost requirements for combustion unit tank and pipes.

Read MoreAtmospheric plasma jet technology rapidly pretreats glass fiber honeycomb sandwich panels

Plasmatreat’s Openair-Plasma system provides composite honeycomb panel manufacturer, MonoPan Composites, with a reliable, high-speed and low-cost dry pretreatment solution for homogeneous wettability.

Read MoreVirgin Orbit automates composites machining processes for LauncherOne rockets

Part of the company’s larger strategy for reducing cycle times and labor costs on its composite-intensive rockets, a customized machine center from Multiax America solves composite machining challenges.

Read More