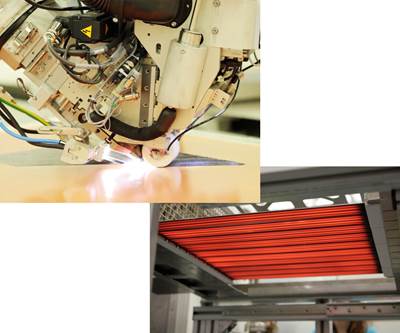

ATL/AFP

Airborne, NCC to develop AFP data warehouse architecture

Using the National Composites Centre’s Automated Fiber Placement (AFP) machine, the project will develop a data warehouse to connect automation with digitalization and enable Industry 4.0.

Read MoreInnovating energy delivery for more efficient composites manufacturing

Heraeus Noblelight develops HUMM3 and Black IR technologies for faster, safer, more uniform processing.

WatchPlant Tour: Veelo Technologies, Woodlawn, Ohio, U.S.

Advanced materials company evolves from nanomaterials to multifunctional composites and processing solutions.

Read MoreIncreasing access to AFP

Addcomposites is democratizing composites manufacturing by leasing a low-cost toolhead that turns any robot into an automated fiber placement machine.

WatchAdvancing additive manufacturing to exploit anisotropy

Anisoprint posits continuous fiber composites, not metals, as the material for optimized AM structures.

Read MoreAirbus selects MSC Software's MaterialCenter platform

The software platform will enable Airbus to more easily manage material workflow from one database across divisions.

Read MoreHighlights: Composites Convention 2019

Highlights from the Composites Convention 2019, June 12-13, in Stade, Germany, organized by CFK Valley e.V. and Carbon Composites e.V, and the German Aerospace Center’s 5th Colloquium on Production Technology, on May 15, in Augsburg.

WatchAddcomposites introduces plug & play AFP/ATL for cost-effective composites manufacturing

New AFP-XS turns any robotic arm into an automated composites manufacturing system.

WatchEU project “ComMUnion” develops industrial process for hybrid metal and polymer-matrix composites

Laser textured steel is joined with continuous fiber-reinforced thermoplastic stiffeners using laser-assisted tape placement for joined structure without adhesives.

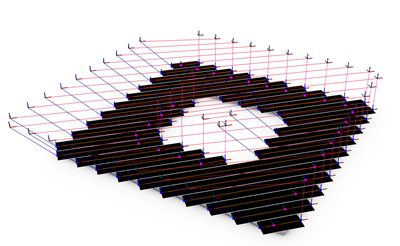

Read MoreGrid/skin structures explained

Composites expert and veteran Stephen Tsai and automated tape and fiber placement specialist MTorres have published “Composite Double-Double and Grid/Skin Structures: Low Weight/Low Cost Design and Manufacturing,” a design and manufacturing guide for the fabrication of grid-stiffened composite structures.

Read More

.jpg;maxWidth=300;quality=90)