Highlights: Composites Convention 2019

Highlights from the Composites Convention 2019, June 12-13, in Stade, Germany, organized by CFK Valley e.V. and Carbon Composites e.V, and the German Aerospace Center’s 5th Colloquium on Production Technology, on May 15, in Augsburg.

- Wind/Energy

- Sustainability

- Sheet Molding Compound

- Carbon Fibers

- Out of Autoclave

- Composites 4.0

- Workforce Development

- NDI

- Materials

- Fabrics/Preforms

- Pressure Vessels

- Adhesives

- ATL/AFP

- Processes

- Resins

- Thermoplastics

- Aerospace

- Feature

- Reinforcements

- Design & Tooling

- Autoclave

- Compression Molding

- Ketones

- Design/Simulation

- RTM

- Curing

- Automation

- Medical

DLR’s intriguingly named Flappybot (Flexible autonomous production, placement and assembly robot) prototype is a radical departure from the large and expensive static machines common in the manufacture of large aerospace components. This compact autonomous AFP unit is designed to ‘drive’ directly over the mold. Source | DLR

If the composites industry is to continue to grow and improve its competitiveness, it must exploit the opportunities that digitization and automation bring. Two recent aerospace-focused conferences in Germany looked at what the future of composites manufacturing could hold.

Visiting the factory of the future in Stade

Future Factory for Composites was the theme for this year’s Composites Convention in Stade, Germany, held June 12-13. Jointly organized by CFK Valley e.V. (Stade, Germany) and Carbon Composites e.V. (Augsburg, Germany), the event attracted a record attendance of nearly 450 people. A strong U.S. presence resulted from a collaboration with the Utah Advanced Materials and Manufacturing Initiative (UAMMI, Kaysville, Utah, U.S.) as partner network and the United States as partner country.

In the opening keynote presentation, titled “Digitization: Transition from Computer Aided Manufacturing to Human Aided Automation,” Dr. Jan Stüve, head of the Center for Lightweight Production Technology at the German Aerospace Center (Deutsches Zentrum für Luft- und Raumfahrt; DLR; Stade, Germany) offered a flavor of the program to come. Future factory technologies under development at DLR include multiple co-operating robots which work together to reduce production time and digital twins of machines which enable process optimization. Another key area concerns mobile autonomous robots for flexible production scenarios. These include the prototype FlappyBot, a compact fiber placement unit that travels over the mold. Stüve warned of the potential dangers of over automation and discussed how digitalization should reinvolve humans in the manufacturing process.

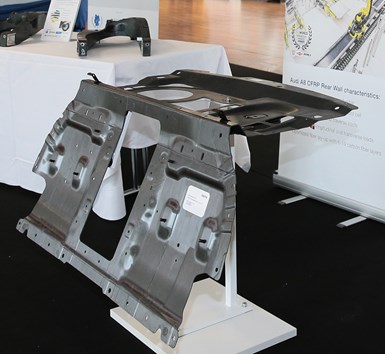

The Audi A8 CFRP rear wall, the largest component of the passenger cell, is manufactured by Voith Composites in a highly automated process enabling production volumes of 65,000 components per year. Source | CFK Valley

In a second keynote, “Rapid Manufacturing and Thermoplastic Composites – Trends and Technologies,” Dr. Robert G. Bryant, senior materials engineer at the NASA Langley Research Center (Hampton, Va., U.S.), took delegates away from the confines of the terrestrial factory toward building in space. A long-term human presence in space will require shelter and platforms as a first step. Development of ever larger rockets to place increasingly complex structures off-planet is not economically sustainable. Solutions require near or on-site manufacturing. The use of a toolless advanced tape placement (ATP) process enabling in-situ consolidation of thermoplastic composite parts could be the answer. In this new technique, two ATP robots work opposite each other, one to deposit the thermoplastic prepreg tape, the other acting as the tool. Toolless fabrication could lower the cost of aerospace manufacturing, improving the economics of space exploration as well as benefiting other market sectors (learn more in “General Atomics Aeronautical developing toolless thermoplastics composites process”).

Sustainability

Advances in manufacturing also must be accompanied by reductions in environmental impact. Along those lines, in the next session, Jörg Spitzner, founder of Spitzner Engineers GmbH (Finkenwerder, Germany), argued that to meet climate targets, negative emissions technologies are needed. Spitzner’s company claims that its patented Blancair wind turbine concept both improves turbine efficiency and removes CO2 from the atmosphere. Air is drawn into a filter module mounted on the nacelle, where CO2 is separated for storage and recycling in the production of synthetic fuels and other applications. The cleaned air is released through openings in the rotor blade tips. A video explaining the concept is available on Blancair’s website.

The session organizers also presented a concept for smart eco-efficiency assessment in composites production (DLR), and out-of-autoclave room-temperature, toughened prepregs with fire, smoke and toxicity (FST) capability (TCR Composites; Ogden, Utah, U.S.).

Empowerment through simulation

For the remainder of the first day of the conference, attention turned to simulation.

Dr. Lars Herbeck, chief technology officer at Voith Composites (Garching, Germany), discussed how the Voith Roving Applicator automated fiber placement (AFP) machine simplifies the process chain, enabling an efficient automated preforming process with reduced cycle times. He outlined the structural and process simulation performed for the automated manufacturing line that capable of producing 65,000 components per year for the Audi A8 carbon fiber-reinforced plastic (CFRP) back rear wall.

Mark Bludszuweit from MET Motoren- und Energietechnik GmbH (Rostock, Germany) explained how simulation offers insight into the best way to load parts into an autoclave, enabling optimization of the curing process and greater productivity. A digital twin developed for the largest autoclave at DLR’s Stade facility can run in parallel with the real process, or faster to offer predictions of part behavior.

Further virtual process development topics covered modeling of SMC processes (ESI Group; Chartres-de-Bretagne, France) and process simulation of sandwich panels to understand core crush and prepreg wrinkling issues in the autoclave (Airbus Helicopters; Marignane, France).

Turning to virtual safety modeling, Jochen Rühl of Reichenbacher Hamuel GmbH (Dörfles-Esbach, Germany), part of Scherdel Gruppe, discussed how a simulation-based approach to managing dust and particulate matter produced during machining of CFRP parts has delivered benefits for customers such as Airbus and Premium Aerotec (Augsburg, Germany). Machining simulations and visualization of particulate distributions helps manufacturers comply with tightening health and safety legislation and improves machining results, as well as reduced machine downtime and maintenance, all of which ultimately translates into a lower cost per part.

The simulation session also showcased a Boeing-sponsored project on virtual cost modeling of composites manufacturing, taking into account the complex interactions between design, production and finance to identify cost drivers (Massachusetts Institute of Technology; Cambridge, Mass., U.S.), and a digital factory planning concept based on simulative modeling of optimal composites value chains (Fraunhofer IGCV; Augsburg, Germany).

The MBFast18 mobile machining concept is composed of an automated guided vehicle, robot and portable CNC machine and offers increased productivity in the manufacture of large CFRP aircraft parts. Source | Fraunhofer IFAM

Award winners

This year, two projects shared the CFK Valley Innovation Award and the €7,500 prize money.

First place (and €4,500) went to the MBFast18 mobile robotic systems project, which developed an automated guided vehicle (AGV)-based mobile CNC machining system for large CFRP aircraft parts.

Source | Fraunhofer IFAM

Compared to today’s expensive, static machining systems for large aircraft structures, smaller mobile robotic systems enable flexible manufacturing and higher productivity.

The MBFast18 system employs a 4.6-meter-long autonomous platform built by FFT Produktionssysteme GmbH & Co. KG (Fulda, Germany), navigation and safety sensors supplied by SICK AG (Waldkirch, Germany), and a 5-axis CNC machine from SAUER/DMG MORI (Suhl and Bielefeld, Germany). A mobile laser tracker developed by the Fraunhofer Institute for Manufacturing Technology and Advanced Materials (IFAM; Stade, Germany) positions the robot precisely. The drilling unit, with a workspace of up to 0.5 square meters, is clamped to the component using vacuum grippers; drilling positions are calculated and transmitted to the machine using software developed by BCT GmbH (Dortmund, Germany). This concept is also applicable to handling and assembly operations and other industries such as wind energy and rail.

Watch a video about the MBFast18 project:

Second place went to start-up Hyconnect GmbH (Hamburg, Germany) for its FAUSST metal-composite joining technology. The company is initially targeting the shipbuilding sector, where the joining of composites to metal is a major barrier to more widespread composites adoption. The FAUSST solution employs a hybrid fabric consisting of warp-knitted glass and metal fibers that allows metals and composites to be firmly joined mechanically. The metal fiber side is joined to a steel profile that can be welded to metal structures, and the other side is laminated to the composite component. The patented technology is said to speed up the design and bonding process significantly. Initial prototype applications are currently under test.

Watch an introduction to the FAUSST joining process:

Enablement through automation

Day Two saw the award-winning MBFast18 project explored in more detail in presentations from Christoph Brillinger, project manager at Fraunhofer IFAM, and Dr. Gregor Graßl of FFT, who discussed the challenges of developing smart process and plant control systems for multi-robot operations. Jerome Berg, staff engineer at Northrop Grumman Innovation Systems (Clearfield, Utah, U.S.), described the automated manufacture of Airbus aircraft stringers at the company’s Utah facility using an in-house developed AFP process, and Uwe Lang of Evonik Resource Efficiency GmbH (Darmstadt, Germany) introduced “Sandwich Technology 4.0,” an automated manufacturing technology for high production rates that employs the company’s ROHACELL foam core material. A highly automated preforming process for an aircraft nose landing gear door has been demonstrated in a collaboration with DLR and Airbus’ technology hub CTC GmbH (Stade, Germany).

Watch a video of the preforming process:

Taking a journey into virtual reality, Felix Hünecke, head of business development at ABSOLUTE Reality GmbH (Hamburg, Germany), showed how 3D models of buildings can be created, edited and supplemented with images, documents and videos to create virtual environments that can be viewed from anywhere in the world. The company created a 3D tour of a DLR production hall in Stade.

Take a walk through DLR’s production hall:

Felix Schreiber, CEO, ARK Group (Aachen, Germany), discussed the process and cost benefits of structured machine data in an automated resin transfer molding (RTM) production line, while Sascha Backhaus of CTC GmbH discussed modular automation in composites manufacturing and the Hybr-iT project, which is developing teams where humans and robots work together with software-based assistance systems.

No event about the future factory could neglect the topic of artificial intelligence (AI), and Amir Ben-Assa, CMO of Plataine (Waltham, Mass., U.S.) discussed the opportunities and challenges of implementing AI in composites manufacturing. He presented practical applications of AI, from alerts (for example, production delays or quality problems) to recommendations (for example, optimized material selection). AI-based digital assistants on Google Glass could be another possibility, offering “hands-free” user interaction with AI on the production floor and real-time audio and visual presentation of alerts.

The Multifunctional Robot Cell at ZLP Augsburg was designed to enable the development of integrated processes for manufacturing large composite components on an industrial scale. Source | DLR

Further topics included:

- Fiber optic sensing for intelligent process monitoring in large composite structures (MT Aerospace AG; Augsburg, Germany);

- An intelligent control system for automated composites manufacturing (National Composites Centre, Bristol, U.K.);

- A model-based quality control system for thermoforming of small components (Faserinstitut Bremen e.V.; FIBRE, Bremen, Germany);

- A process for compression molding of discontinuous fiber-reinforced thermoplastics for aircraft applications, based on flexible automation and scalable to large part size (ACT Aerospace; Gunnison, Utah, U.S.);

- An isothermal RTM process offering reduced cycle times for high-volume CFRP part production (Airbus Helicopters)

- Large-scale production of complex, carbon fiber, high-performance thermoplastic profiles for struts, pipes and driveshafts using near net-shaped tape preforms and injection forming (herone GmbH; Dresden, Germany). Learn more about herone and this process in “Injection-forming for high-performance, unitized thermoplastic structures.”

10 years of progress in Augsburg

In a separate event, the DLR’s 5th Colloquium on Production Technology on May 15 saw close to 200 guests gather at its Center for Lightweight Production Technology (Zentrum für Leichtbauproduktionstechnologie, ZLP) in Augsburg. The event celebrated ZLP’s 10th year in Augsburg, where today approximately 60 staff focus on automation and digitalization of composites production.

A robotic gripper for automated draping, part of ZLP Augsburg’s integrated manufacturing process for full-scale structural components. Source | DLR

The day kicked off with two presentations from the University of British Columbia (UBC; Vancouver, Canada), which commenced a cooperation with DLR in 2016. Prof. Dr. Anoush Poursartip, co-director of UBC’s Digital Learning Factory Initiative, introduced the concept of a learning factory for composites inspired by medical teaching hospitals. The composites learning factory, to be located on UBC’s Okanagan campus, will be designed to integrate research and education with industrial activities. A digital twin hosted at UBC Vancouver will combine data from the physical factory with simulation to optimize aerospace composites production processes. Next, UBC’s Prof. Dr. Homayoun Najjaran and DLR’s Marian Körber discussed optimization of complex manufacturing processes in a virtual environment, and how UBC’s expertise in machine learning techniques and artificial intelligence are being used to reduce the time and cost of robotic systems development at DLR. A deep learning method was used to train ZLP’s robotic gripper for automated draping, a key part of the Augsburg facility’s automated process chain for manufacturing large CFRP parts. The gripper, which features 127 suction modules with variable suction force, recognizes and picks cut material; the modules assume the geometry required for draping it into position in the mold.

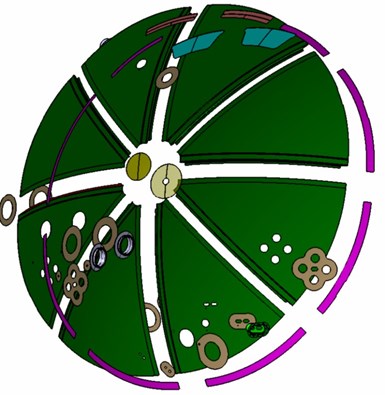

The thermoplastic composite components for Premium Aerotec’s rear pressure bulkhead design are joined using a resistance welding technique developed at ZLP Augsburg. Source | Premium Aerotec

Thermoplastics technologies are another focus for ZLP Augsburg. A project to develop the world’s first thermoplastic rear pressure bulkhead (RPB) for single-aisle aircraft was outlined by Ralph Männich and Alexander Sänger of Premium Aerotec GmbH. The company is collaborating with ZLP Augsburg, Toray Advanced Composites and the Institute for Composite Materials (IVW) on a design consisting of eight CFRP segments with integrated stringers joined using a ZLP-developed resistance welding technology. Automated processes with short cycle times enable high-volume production. Technology completion (to TRL 6) is scheduled for 2020 with implementation targeted for 2021/2022. At June’s Paris Air Show, Premium Aerotec displayed a 1:1 demonstrator for an Airbus A320 series aircraft. Compared to current A320 pressure bulkheads made of riveted aluminum components, the thermoplastic part is said to deliver the same mechanical properties with 10-15% weight savings and a 50% reduction in production time. In the following talk, DLR’s Dr. Stefan Jarka and Manuel Endraß continued the theme of thermoplastic welding, delving deeper into ZLP Augsburg’s joining and NDT capabilities, and its role in the RPB project.

ZLP Augsburg is investigating flash lamp-based in-situ AFP of thermoplastic composites, a pulsed energy solution which eliminates the safety enclosures required for laser-based AFP. Source | DLR

Thermoplastic composites also offer opportunities in space applications. Presentations from Ralf Hartmond, MT Aerospace AG and Lars Brandt, project manager for space-related applications at DLR, outlined the development of a carbon fiber-reinforced thermoplastic upper stage for the next-generation Ariane rocket launcher. Brandt detailed DLR’s work on materials screening for the liquid hydrogen tank (LH2) tank — where carbon fiber PEEK and low-melt (LM) PAEK offer promise — and development of an in-situ thermoplastic composite AFP process to enable a lean additive manufacturing approach. ZLP is benchmarking a new flash lamp-assisted in-situ AFP process against traditional laser-assisted AFP.

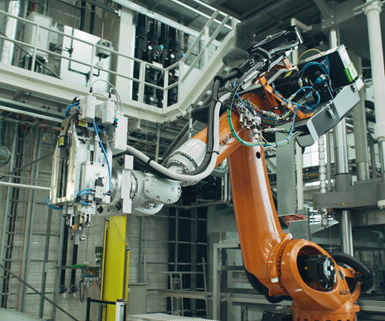

Joining technologies will be key to the successful introduction of thermoplastic composites in future aerospace applications. ZLP in Augsburg has developed a robot-based continuous ultrasonic welding system consisting of an end-effector mounted on a KUKA QUANTEC KR210 robot on a 7 m linear track. This has been proven on components including a stiffened fuselage panel and a rear pressure bulkhead. Source | DLR

The day concluded with a thought-provoking keynote from Prof. Dr. Michael Kupke, head of ZLP Augsburg, entitled “Digitalisation and Flexible Production.” He asked if the rise of the digital platform economy presents opportunities or risks for composites manufacturers, and pointed out that IT is becoming a core competence and should be treated as a value-adding competitive advantage rather than a cost center. He also said there is an ongoing paradigm shift from detailed planning to self-organization (lean production) and automation combined with digitalization. AI, he says, makes autonomous, flexible production possible. However, Kupke concluded, it is essential to value and integrate human skills, which are vital for decision-making and process improvement.

Related Content

Plant tour: Sekisui Aerospace, Orange City, Iowa, Renton and Sumner, Wash., U.S.

Veteran composites sites use kaizen and innovation culture to expand thermoplastic serial production, 4.0 digitization and new technology for diversified new markets.

Read MoreST Engineering MRAS presents initiatives to drive autoclave efficiency, automation

During a JEC World 2024 panel discussion, the company revealed ways in which it is maximizing throughput and efficiency of its autoclaves and enhancing composites production processes.

Read MoreHow AI is improving composites operations and factory sustainability

Workforce pain points and various logistical challenges are putting operations resilience and flexibility to the test, but Industry 4.0 advancements could be the key to composites manufacturers’ transformation.

Read MoreAerotech Academy Puglia is inaugurated at Leonardo Aerospace site in Grottaglie, Italy

Joining the Leonardo MaTeRIA Lab and Joint Lab with Syensqo, this aerostructures training course will be 75% materials science and structural design/analysis, 25% digital transformation and AI.

Read MoreRead Next

Plant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More