ATL/AFP

Proving out LM PAEK welding for Multifunctional Fuselage Demonstrator

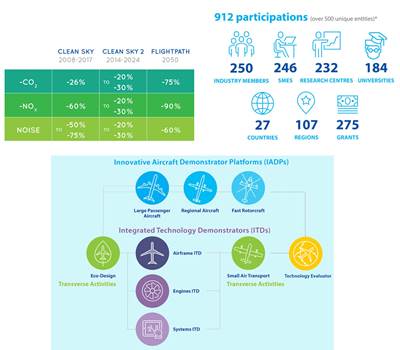

Clean Sky 2 STUNNING project will manufacture lower thermoplastic fuselage while MECATESTERS will test Toray LM PAEK in conduction and induction welding for parameters, cyclic loading, aging and environmental effects .

WatchUsing mobile susceptors to innovate thermoplastic induction welding

IS Groupe and Arkema patent ISW for high-strength UD welds, temperature control and 50% less energy.

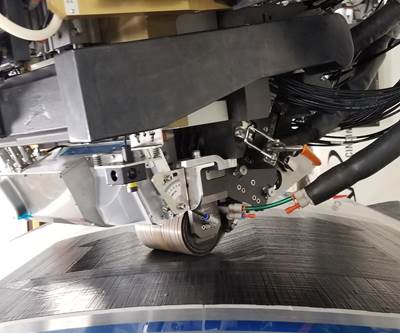

Read MoreIRT Jules Verne, Airbus and Fives launch MADRAS automated textile deposition line for WING project

Goal is full-scale testing of large, complex shape preforms at 5-6 times faster speeds for future aircraft.

WatchMikrosam to supply ATP machine for UD-CCM research

Initial University of Delaware studies conducted with the automated tape placement (ATP) machine will evaluate placement of thin ply materials to support current projects with NASA.

Read MoreRolls-Royce starts manufacture of world's largest fan blades, made with composites, for UltraFan demonstrator

CFRP blades and fan case cut weight for twin-engine aircraft by 700 kilograms

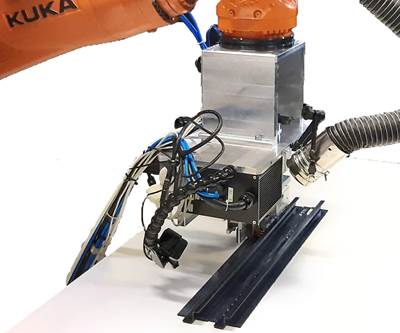

WatchConbility tape placement head installed at University of Limerick

The PrePro 3D system combines laser-assisted thermoplastic tape placement with IR-assisted thermoset prepreg placement.

Read MoreJEC announces finalists for 2020 Innovation Awards

JEC Group has announced its JEC Innovation Awards finalists, 33 total from 11 categories. Winners will be announced at JEC World 2020 on March 4.

Read MoreCevotec, Fuji sign exclusive sales partnership for Japan and Thai markets

Japan-based Fuji Industries has exclusive rights to sell Cevotec products in the region, including Fiber Patch Placement composites automation technology.

Read MoreAVK invites submissions for Innovation Award 2020 candidates

Award categories include innovative composite applications, processes or research. The application deadline is March 31.

Read MoreCevotec scales up Fiber Patch Placement technology for large aerostructures

The SAMBA Step L automated fiber placement system can place patches of material up to 50 times larger than previous FPP systems.

Read More

.jpg;maxWidth=300;quality=90)