Autoclave

Fiber-metal laminates in the spotlight

Interest in FMLs is growing again as aeroengineers search for lightweight solutions adaptable to new narrowbody commercial aircraft.

Read MoreUnweighting a crane to increase payload limit

Rethinking a crane stinger with carbon fiber for a more “uplifting experience.”

Read MoreThinking outside the prepreg box in aerospace

A challenge to “outside the box” thinking about prepreg.

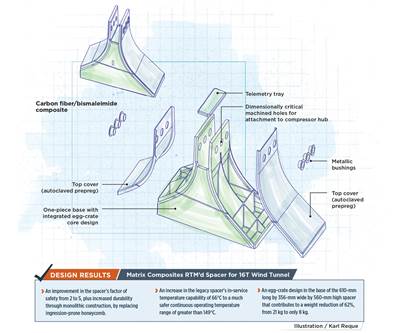

Read MoreRTM-based redesign advances safety for one-of-a-kind wind tunnel

Glass fiber and honeycomb spacers between compressor blades get upgraded to a higher factor of safety with less weight using solid carbon fiber and RTM.

Read MoreArevo composite additive manufacturing: the future of AFP?

Its multi-axis, continuous fiber technology eliminates tooling, matches strength of titanium parts at 1/3 the weight and cuts part cost vs. hand layup/autoclave cure by a factor of 5.

Read MorePlant Tour: GE Aviation, Asheville, NC, US

An avant-garde approach to unprecedented CMC parts production.

Read MoreAutomated Preforming, Part 2: Glide Forming

Flat layups are shaped into stringers with different cross-sections, lengths, thicknesses and curvatures using a single machine at rates up to 10 mm per second.

WatchAn aerocomposites wish list

Boeing R&T fellow Tom Tsotsis offers his vision of how design and manufacture of composite parts and structures might evolve in the aerospace industry.

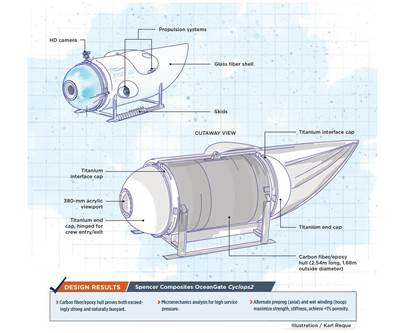

Read MoreComposite submersibles: Under pressure in deep, deep waters

Manned deepsea exploration calls for a highly engineered composites solution that saves weight and preserves life — at 6,500-psi service pressure.

Read MoreEuropean SAMPE meeting explores composites innovation

High spots from SAMPE Europe’s Summit 17.

Read More