Autoclave

The emerging commercial space industry

A decade since NASA opened extraterrestrial space to potential use as a commercial industry workplace, CW traces the role composites have played in public/private progress toward that goal.

Read MoreAirbus Helicopters verify performance of 410km/h Clean Sky 2 demonstrator

X3-based, compound VTOL airframe configuration nears final design but exact use of composites yet to be detailed

Read MoreMS-21 OOA wing and wing box near first flight

Irkut Corp. rolled out the MS-21 single-aisle commercial aircraft on June 8, and we were reminded of its remarkable novelty: It features the first out-of-autoclave composite wing and wing box.

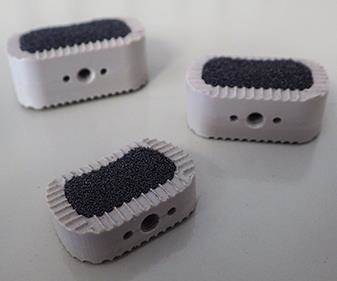

WatchOrthopedics: Carbon foam fosters bone growth

The Center of Innovation for Biomaterials in Orthopedic Research (CIBOR) at the National Institute for Aviation Research (Wichita, KS, US) has two patents on the use of carbon foam as a bone-graft material to improve success in orthopedic implants.

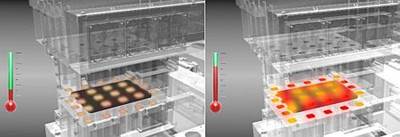

Read MorePixelated temperature control

Surface Generation is providing digital process control for composites molding that cuts energy use, cycle time and processing pressures while breaking boundaries in thickness, complexity and embedded elements.

Read MoreComposites manufacturing — where the excitement lives

A regular CW columnist and the chief commercialization officer for the Institute for Advanced Composites Manufacturing Innovation (IACMI, Knoxville, TN, US), Dale Brosius points out that for today's engineering students, a Ph.D in manufacturing could open the door to an exciting, alternative career path.

Read MoreCarbon/epoxy Cadillac hood

Automated process for prepreg hood inner/outer cuts weight by 20% and yields Class A exterior out of the autoclave.

Read MoreUsing 3D printing for composite molds and tools: the trend continues

Additive manufacturing (AM), or 3D printing, is becoming more common in the aerospace tooling realm. Production tooling can be made quickly and on-demand, which helps the tooling industry keep pace with accelerating composite part design cycles and demand for faster overall part processing speeds.

Read More3-D printing autoclavable composite molds

The polymer additive manufacturing research team at the Department of Energy’s Manufacturing Demonstration Facility at Oak Ridge National Laboratory reports that it has successfully fabricated autoclave-capable carbon fiber composite molds, manufactured using large-scale 3D printing/additive manufacturing.

Read MoreCost-effective aerocomposites: Dry fiber AFP and resin infusion

Aurora Flight Sciences and NONA Composites aim to improve toughness, repeatable aerospace quality and affordability for large-scale NASA structures.

Read More

small.jpg;maxWidth=400;quality=70)

.jpg;maxWidth=300;quality=90)