Robotic injection molding for functionalized composites

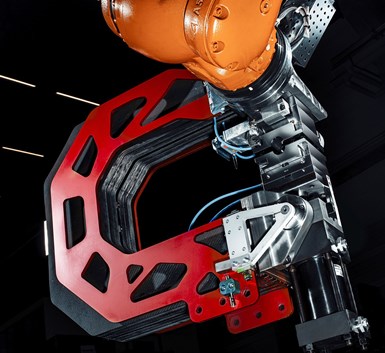

Anybrid enables compact, flexible hybrid injection molding/overmolding for smaller series and larger components.

Photo credit: Anybrid GmbH

Anybrid GmbH (Dresden, Germany) is a spin-off from the Institute for Lightweight Engineering and Polymer Technology (ILK) at TU Dresden. ILK works with industry to develop new lightweight technologies, with a focus on reinforced polymer composites. “We developed this robotized injection molding machine two years ago for producing hybrid components,” says Michael Stegelmann, chief commercial officer at Anybrid. Hybrid components refers to functionalizing a structure — for example, a composite tube or metal electric vehicle chassis — with injection-molded plastic to create local attachment points, stiffening ribs, etc.

This process, referred to as overmolding or hybrid injection molding, has gained a lot of attention over the past 5-6 years, but in a more traditional form — steel molds in a molding press with an attached injection unit. Anybrid has essentially miniaturized this setup into the red and black, C-shaped end effector shown on the Kuka robot in the image above and video below. The result is revolutionary, enabling pultrusions or extrusions to be overmolded as they exit the molding die or large structures to be functionalized as they move down an assembly line.

ROBIN

ROBIN, short for “robotized injection molding”, was first presented in 2019 at the K show in Dusseldorf, Germany. “We then founded the company last year and are now working with customers to establish pilot production lines using the equipment,” says Stegelmann. The concept, he explains, is to reduce the mass of the injection molding machine by using small injection units and compact, inexpensive molding tools that can be quickly exchanged.

Carbon fiber-reinforced polymer components reduce the weight of the ROBIN end effector. Photo credit: Anybrid GmbH

“The ROBIN end effector comprises a C-frame made of carbon fiber composite and on the outside you see an aluminum frame,” explains Stegelmann. “The frame contains the lightweight locking system, which handles up to 12 tons of loading forces during injection molding, brought from the upper side to the lower side of the mold.” ROBIN can also reach out to a 1-meter cantilever across large structures. “This is our know-how within ILK — how to use carbon fiber and lightweight materials in the right way.”

The traditional approach to injection molding requires large presses and expensive molding tools. Thus, it has been limited to large-series/high-volume production. In contrast, ROBIN enables manufacturing of small series or multiple, different moldings on larger components. “The principle is that we have such a flexibility in the machines that we can functionalize almost any composite material or structure,” notes Stegelmann.

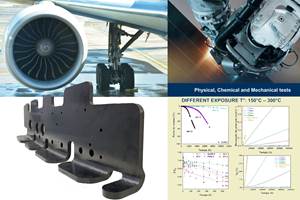

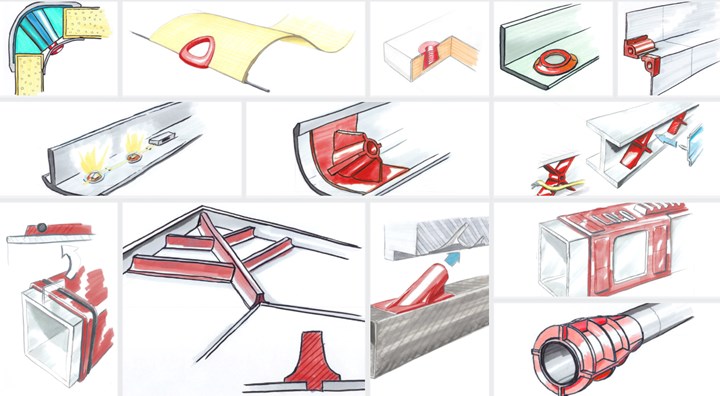

Anybrid’s mobile injection molding approach provides an affordable means for a wide variety of functionalization — e.g., inserts for fasteners and LED lights, localized stiffeners and customized end-fittings — to composite pipes, tubes, profiles, plates and even larger structures, providing the flexibility needed for future manufacturing. Photo credit: Anybrid GmbH

“We try to minimize the size of the molds to reduce costs, so you just need a few thousand euros to build the mold,” Stegelmann explains. “This allows an integrated quick change-out system because only a small mold area has to be changed. The idea, for example, is that you have an assembly line with the possibility to quickly change the mold and do a different part on two different sides of the line. You can either use two Robin systems or one Robin system and quickly change the mold. So, you have high flexibility.”

This reduction in size does limit the area that can be overmolded. “At the moment, we are limited to 50-60 grams for the injection shot,” says Stegelmann. “We developed ROBIN to weigh just 140 kilograms, which makes it possible to use smaller, more affordable automation. We are focusing right now on functionalizing pipes and profiles and adding smaller elements to larger structures.”

Achieving a good bond in overmolding

“This is actually our background,” says Stegelmann, referring to Anybrid’s four co-founders. “We did this in a lot of projects over the last 10 or 15 years, combining different materials and finding the right bonding, I did my PhD on extrusion processes, and it's always challenging when you are combining different materials. You always need some additional preparation for bonding like plasma treatment or laser treatment, to alter the surface structure, especially when bonding plastic or reinforced plastic onto metal. Composites are a bit easier, because you can match the polymer matrix in the injection molding material and the substrate.”

For example, in the overmolded tube shown below, Mitsui Chemicals Europe (Dusseldorf, Germany) supplied the carbon fiber-reinforced polypropylene (PP) unidirectional (UD) tapes and INOMETA (Herford, Germany) used these to produce composite tubes, which Anybrid then overmolded. “The functionalization was the same material as the pipes are made of,” says Stegelmann. “We overmolded it with both unreinforced and carbon fiber-reinforced PP material, but also with glass fiber reinforcements as well. With ROBIN, you can manufacture with any thermoplastic material that is on the market.”

The latter is why Anybrid assists its customers with testing. “We get customers that are not sure if their materials will bond to each other,” notes Stegelmann. “We ask them to send us some of the material and we then make some small, simple structures to test. We have a small mold for a stiffening rib that we can injection mold onto different plates. For example, if the customer sends us samples of some composite plates, we can overmold onto these with their injection molding materials. That's the first step, that we have a feasibility study of the bonding behavior of the different materials. After that, we can do some analysis and offer suggestions for optimization.”

Potential applications

ROBIN is used to functionalize pipes and tubing made from CFRP and other materials.

“We are still exploring applications, but we are initially working with pipes and profiles,” says Stegelmann. “One of our ideas is to sequentially bring different structures onto these continuous, potentially very long shapes,” says Stegelmann. “So, elements can be applied directly to pipes. Such concepts are already being used by INOMETA and Herone (Dresden, Germany) to integrate axial connection systems and form-fitting gears. This also might be interesting in the aviation industry, where you need various stiffness enhancements and perhaps want to add functions such as attachments. Also, you may have a stringer or frame, for example, but many variations in length. With our technology, there is the possibility to maintain a high level of automation and just vary the elements that you are functionalizing from one part to the next.”

“There is also potential with large components,” says Stegelmann. “Working at ILK for the last years, we developed many different hybrid components using steel, plastic and composites. We could see that overmolded clips on structural frames and chassis makes sense for assembly. And with the move to electric vehicles and hydrogen systems, we see that it is important to make assembly lines and processes as flexible as possible, to prepare for a variety of different components that may be needed in the future. With ROBIN, you can easily adjust local enhancements for assembly but also for stiffness of the structure, for example. However, we want to extend this capability beyond just automotive and aerospace. Our idea was to make this more affordable for small companies and enable this hybrid technology for smaller quantities in other fields and other applications.”

Related Content

Partners recycle A350 composite production waste into adjustable-length rods for MFFD

Herone, Spiral RTC, Teijin Carbon Europe and Collins Aerospace Almere recycle A350 thermoplastic composite clips/cleats waste into rods for the all-thermoplastic composite Multifunctional Fuselage Demonstrator’s crown.

Read MoreRecycling end-of-life composite parts: New methods, markets

From infrastructure solutions to consumer products, Polish recycler Anmet and Netherlands-based researchers are developing new methods for repurposing wind turbine blades and other composite parts.

Read MoreDaher CARAC TP project advances thermoplastic composites certification approach

New tests, analysis enable databases, models, design guidelines and methodologies, combining materials science with production processes to predict and optimize part performance at temperatures above Tg (≈150-180°C) for wing and engine structures.

Read MoreMicrowave heating for more sustainable carbon fiber

Skeptics say it won’t work — Osaka-based Microwave Chemical Co. says it already has — and continues to advance its simulation-based technology to slash energy use and emissions in manufacturing.

Read MoreRead Next

Overmolding as enabler for composites, aerospace to automotive

CCP Gransden can make 50 to 100,000 parts/yr economically viable using PEEK, PPS, PEI or PA.

Read MoreInjection-forming for high-performance, unitized thermoplastic structures

Combining braided tape, overmolding and form-locking, herone produces one-piece, high-torque gear-driveshaft as demonstrator for broad range of applications.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read More