Composites Basics

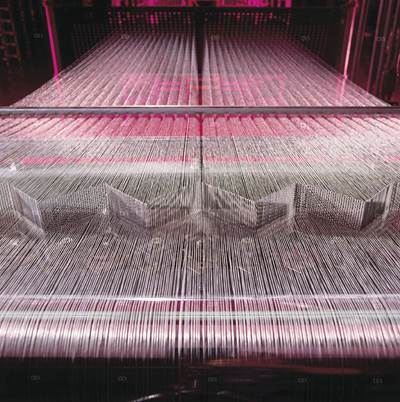

The making of glass fiber

The old art behind this industry’s first fiber reinforcement is explained,with insights into new fiber science and future developments.

Read MoreHow to help CW help you and our audience

It’s more important than ever that you communicate with us about your company’s new products, new technologies, expansions and other activities.

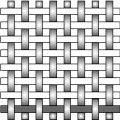

Read MoreWoven fabrics: The basics

For composite applications requiring more than one fiber orientation, woven fabrics can be useful. This primer outlines the basics of woven fabrics and different types.

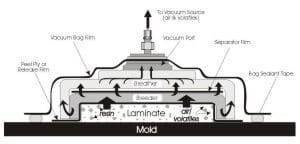

Read MoreVacuum bagging: The basics

A primer on the reasons to use vacuum bagging in composite part manufacture, and the basics of how to do it

Read MoreCore materials: The basics

Core materials available for composite sandwich structures range from paper, aluminum and thermoplastic honeycomb cores to foams and more.

Read MoreAramid fiber: The basics

Aramid fiber is a manmade organic polymer (an aromatic polyamide) produced by spinning a solid fiber from a liquid chemical blend. The fibers offer high strength among other properties.

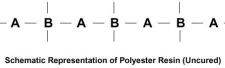

Read MorePolyester resins: The basics

Polyester resins are widely used resin systems. Learn more about their chemical makeup and how they are used in the composites industry.

Read MoreAddcomposites' virtual demo on how to make an AFP composite laminate

Readers are walked through how to program and operate the AFP-XS plug and play system.

Read MoreComposites 101: Tutorials at CAMX

While CAMX generally holds its educational tutorial sessions on Monday before the show opens, this year a second slate of sessions will be held today.

Read MoreWebinar: Building a Case for Automated Composite Lay-up

CompositesWorld is presenting a free CGTech sponsored webinar on Thursday June 21, at 2:00 p.m. EDT, on automated composite lay-up.

Read More